ASTM A312 353 MA 1.4854 Stainless Steel Tubing and Pipes

ASTM A312 ASME SA312 353 MA UNS S35315, EN 10297 - 2 1.4854 is an austenitic, chromium-nickel steel contributing to longer tube life and reduced maintenance in a wide range of high temperature applications. Alloyed with nitrogen and rare earth metals (REM), 353 MA is characterized by high performance in oxidizing, carburizing and nitriding environments.

Alloy 353 MA is a strong, micro-alloyed austenitic with oxidation resistance through 2300° F. Carburization, oxidizing hot corrosion resistance. The upgrade from Alloy 330 was developed as a filler alloy for alloy 2219 that is widely used in high strength structural and aircraft applications where superior resistance to stress corrosion cracking and high elevated temperature properties are desired. This alloy is heat treatable and provides higher strength and better ductility than the 4xxx filler alloys when welding 2xxx alloys.

Good weldability of 353 MA. Suitable welding methods are manual metal-arc (MMA) welding with covered electrodes and gas shielded arc welded with the TIG and MIG methods as first choice. Preheating and post-weld heat treatment are normally not necessary.

Compared with cast alloys, wrought alloys, such as 353 MA, can be produced in longer lengths. The longer length gives cost advantages, since less welding is required during fabrication of furnace coils. Wrought materials are also more ductile at room temperature. Consequently, welding is easier, especially after service exposure. Both cold bending and hot bending are possible depending on tube dimensions and the bending radius.

ASTM A312 S35313 Chemical Composition

| C |

P |

Mn |

S |

Si |

Cr |

Ni |

N |

Ce |

| 0.04-0.08 |

0.040 |

2.00 |

0.030 |

1.2-2.0 |

24.0-26.0 |

34.0-36.0 |

0.12-0.18 |

0.03-0.08 |

Mechanical Properties

Tensile Strength 87Ksi (600Mpa) min, Yield Strength 38Ksi (260 Mpa) min

Physical Properties

Melting Range: 1010-1190° F

Density: 7.90 g/cm3 / 0.285 lb/in3

Resistance to corrosion: D (Gen) C(SCC)

Anodize Color: Golden

Application

Some typical applications are:

- Welding Filler Wire

- Ethylene furnace, radiant cracking tubes

- EDC furnace tubes

- Tubes in wast heat recovery systems in the metallurgical industry, e.g. recuperators

- Tubes in heat treatment furnaces, e.g. muffle tubes, radiant tubes, thermocouple protection tubes, burner components, furnace rollers

- Recuperator tubes in chemical waste and sewage sludge incineration

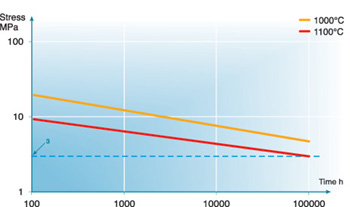

High creep strength

353 MA exhibits very good creep properties at high temperature and its creep strength meets the design requirements of steam cracking furnace tubes. The material's high content of nitrogen contributes to the high temperature strength.

Comparing 353 MA with cast alloys, it can be seen that the creep strength is not as high. The additional strength in cast material is, however, normally not utilized, since the limiting factor for tube life is carburization and time between decoking.

Visual Testing

100% PMI Testing

Hydraustatic Testing

Plywood Cases Package

Iron Frame Plywood Case Package

|