Surface Finish for Stainless Steel Sheet Plate Coil Strip

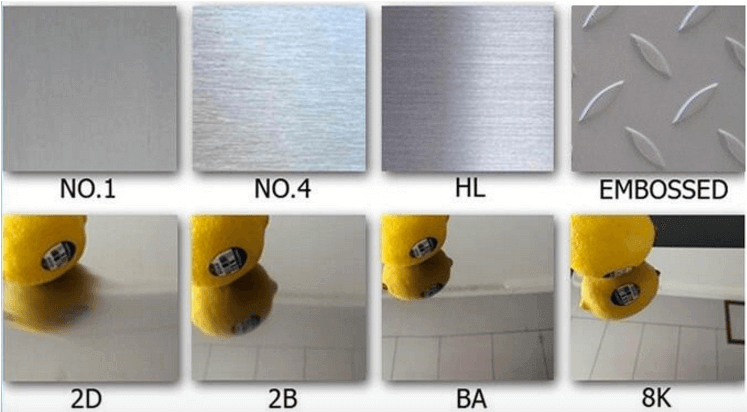

Surface finish for stainless steel sheet (coil, strip) and plates, are specified in EN 10088-2:2005. 'Stainless steel - Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes.' The standard identifies both 'ex-mill' hot and cold rolled finishes and 'special finishes', as value added finishes to achieve specific aesthetic effects.

Most of the finishes available have a surface that provides a high standard of corrosion resistance, up to the limit of the compositional potential of the particular grade. The coarser finishes (eg finish 'G') may limit the corrosion resistance of the steel in severe applications, where the particular grade is operating in conditions close to the limit of its corrosion resistance. In numeric or quantitative terms this is very difficult to define and is often a matter of judgement.

EN 10088-2 Surface Finishes

Table 6 of EN 10088-2 defines finishes for both

Ex-mill Hot Rolled Finishes

Ex-mill Cold Rolled Finishes

'Special Finishes'

The definitions of surface finish do not attempt to express surface finish in terms of the surface topography achieved in terms of Ra values. The standard uses a coding system based on the manufacturing process. A full definition is shown in the standard, with appropriate notes in terms of:

Type of process route

Surface finish

To precisely define a 'special finish' for a particular application where a specific aesthetic texture or appearance is required usually involves close consultation with specialist finishers, as surface characteristics can vary.Once the grade of finishing grit has been defined, the final acceptance of special finishes is often done by using reference 'swatch' samples.

Ex-mill hot rolled finishes

The table shows the EN 10088-2 hot rolled finishes from table 6 of the standard, with a guide to typical Ra values (in micro-metres) , based, where available, on manufacturers or surface finishing contractors' data.

| Ex-mill Hot Rolled Finishes |

| Abbreviation |

Finishing Process Route |

Notes |

Typical (Ra) micro-metres |

| 1C |

Hot rolled, heat treated, not descaled |

Surface covered with mill scale. Finished parts may be suitable for heat (oxidation) resisting applications as supplied, but should be descaled to optimise corrosion resistance |

. |

| 1E |

Hot rolled, heat treated, mechanically descaled |

Free of mill scale by shot blasting or grinding. This finish can also limit the crevice corrosion resistance |

. |

| 1D |

Hot rolled, heat treated, pickled |

Most common 'hot rolled' finish available. Most corrosion resistant hot rolled finish specified |

4-7 |

| |

| 1U |

Hot rolled, not heat treated, not descaled |

Surface is left covered with rolling (mill) scale. Surface suitable for products intended for further working eg strip for re-rolling. |

- |

Ex-mill cold rolled finishes

The table shows the EN 10088-2 cold rolled finishes from table 6 of the standard, with a guide to typical Ra values (in micro-metres) , based, where available, on manufacturers or surface finishing contractors' data.

| Ex-mill Cold Rolled Finishes |

| Abbreviation |

Finishing Process Route |

Notes |

Typical (Ra) micro-metres |

| 2B |

Cold rolled, heat treated, pickled, skin passed |

Most common 'cold rolled' finish available. Non-reflective, smooth finish, good flatness control. Thickness range limited by manufactures' skin passing rolling capacity. |

0.1-0.5 |

| 2C |

Cold rolled, heat treated, not descaled |

Smooth with scale from heat treatment, suitable for parts to be machined or descaled in subsequent production or where the parts are for heat resisting applications. |

- |

| 2D |

Cold rolled, heat treated, pickled |

Thicker sheet size ranges. Smoothness not as good as 2B, but adequate for most purposes. |

0.4-1.0 |

| 2E |

Cold rolled, heat treated, mechanically descaled |

Rough and dull. Usually applied to steels with a scale which is very resistant to pickling solutions |

- |

| 2H |

Cold rolled, work hardened |

"Temper" rolling on austenitic types improves mechanical strength. Smoothness similar to 2B |

- |

| 2R |

Cold rolled, bright annealed |

Highly reflective "mirror" finish, very smooth. Often supplied with plastic coatings for pressings. Manufactured items usually put into service without further finishing |

.05-0.1 |

| 2Q |

Cold rolled, hardened and tempered, scale free |

Only available on martensitic types (eg 420). Scaling avoided by protective atmosphere heat treatment or descaling after heat treatment |

- |

Special finishes

The table shows the EN 10088-2 special finishes from table 6 of the standard, with a guide to typical Ra values (in micro-metres) , based, where available, on manufacturers or surface finishing contractors' data.

| Special Finishes |

| Abbreviation |

Finishing Process Route |

Notes |

Typical (Ra) micro-metres |

| 1G or 2G |

Ground |

Can be based on either '1' or '2' ex-mill finishes. A unidirectional texture, not very reflective |

- |

| 1J or 2J |

Brushed or dull polished |

Can be based on either '1' or '2' ex-mill finishes Smoother than "G" with a unidirectional texture, not very reflective |

0.2-1.0 |

| 1K or 2K |

Satin polished |

Can be based on either '1' or '2' ex-mill finishes Smoothest of the special non-reflective finishes with corrosion resistance suitable for most external applications. |

less than0.5 |

| 1P or 2P |

Bright polished |

Can be based on either '1' or '2' ex-mill finishes Mechanically polished reflective finish. Can be a mirror finish. |

less than 0.1 |

| 2F |

Cold rolled, heat treated, skin passed on roughened rolls |

Uniform non-reflective matt surface, can be based on either 2B or 2R mill finishes |

- |

| 1M or 2M |

Patterned |

Can be based on either '1' or '2' ex-mill finishes. One side patterned only. Includes "chequer" plates ("1" ex-mill finish) & fine textures finishes ("2" ex-mill finish) |

- |

| 2W |

Corrugated |

Profile rolled (eg trapezoidal or sinusoidal shapes) |

- |

| 2L |

Coloured |

Applied to flat (2R, 2P or 2K type fishes) or patterned (2M) sheet base finishes in a range of colours |

- |

| 1S or 2S |

Surface coated |

Can be based on either '1' or '2' ex-mill finishes . Normally coated on one side only with a metallic coating, such as tin, aluminium or titanium |

- |

Electropolished finishes are not covered in EN 10088-2 table 6. The process is however covered by ISO 15730 and is outlined in the technical article Electropolishing of Stainless Steel

Shot blast, shot peen and glass bead peening surface finish processes are not covered by EN 10088-2 table 6. There is no British Standard that specifically deals with specifying these finishes on stainless steel. US Military Specification MIL-S-13165 is used by some contract finishers for specifying the control of shot peening of metal parts.

Comparison of current surface finish codes with BS 1449 (obsolete)

The table gives an indication of how different surface finish specifying systems define similar finishes, in relation to EN 10088-2.

| - |

Description |

BS1449-2 |

DIN |

ASTM (A480) |

| 1D |

Hot rolled, heat treated, pickled |

1 |

IIa (c2) |

1 |

| 2B |

Cold rolled, heat treated, pickled, skin passed |

2B |

IIIc (n) |

2B |

| 2D |

Cold rolled, heat treated, pickled |

2D |

IIIb (h) |

2D |

| 2R |

Cold rolled, bright annealed |

2A |

IIId (m) |

BA |

| 2G |

Cold rolled, ground |

3A |

- |

No.3 |

| 2J |

Cold rolled, brushed or dull polished |

3B (or 4) |

- |

No.4 |

| 2K |

Cold rolled, satin polished |

5 |

- |

No.6 |

| 2P |

Cold rolled, bright polished |

8 |

- |

No.8 |

Related References:

1. Patterned Stainless Steel Finishes and Application

2. Mechanical Polished Brushed and Buffed Stainless Steel

3. Surface Finish for Stainless Steel Sheet Plate Coil Strip

4. Coloured Stainless Steel Finishes and Application

5. Bead and Shot Blasted Stainless Steel Finishes Application

|