ASTM B395 C28000 C44300 C68700 C70600 C71500 U Bend Copper Alloy Heat Exchanger and Condenser Tubes

ASTM B395 C28000 C44300 C68700 C70600 C71500 U Bend Copper Alloy Heat Exchanger and Condenser Tubes are manufactured in our plant as per the customer requirements.

ASTM B395 C28000 C44300 C68700 C70600 C71500 U Bend Copper Alloy Heat Exchanger and Condenser Tubes Temper:

- Prior to U-bending, tubes of Copper Alloy UNS Nos. C23000, C44300, C44400, C44500, C60800, C68700, C70400, C70600, C70620, C71000, C71500, C71520, and C72200 shall be in the annealed temper (O61), unless other- wise specified in the purchase order.

- Prior to bending, U-bend tubes of Copper Alloy UNS Nos. C10200, C10300, C10800, C12000, C12200, and C14200 shall be in light drawn temper (H55). Tubes of Copper Alloy UNS Nos. C70400, C70600, C70620, and C72200 shall, if specified, be made in the light-drawn temper (H55).

- Prior to bending, U-bend tubes of Copper Alloy UNS No. C19200 shall be in the annealed (O61) or light drawn temper (H55) as specified.

- Prior to bending, U-bend tubes of Copper Alloy UNS No. C71500 or C71520 shall be made in the drawn, stress- relieved temper (HR50), when specified.

The U-bend portion of tubes furnished in Copper Alloy UNS Nos. C23000, C44300, C44400, C44500, C60800, and C68700 shall be relief annealed (HR) after bending. If specified, the U-bend portion of tubes furnished in Copper Alloy UNS Nos. C70400, C70600, C70620, C71000, C71500, C71520, and C72200 shall be relief annealed (HR) after bending.

Related Standard Specification:

B153 Test Method for Expansion (Pin Test) of Copper and Copper Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B224 Classification of Coppers

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

B858 Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

B900 Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

B968/B968M Test Method for Flattening of Copper and Copper-Alloy Pipe and Tube

E3 Guide for Preparation of Metallographic Specimens E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)4

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper-

Chromium Alloys (Withdrawn 2010)4

E243 Practice for Electromagnetic (Eddy Current) Examina- tion of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys E2575 Test Method for Determination of Oxygen in Copper

and Copper Alloys

U Bend Tube Application

U tube heat exchangers designed for high temperature applications, especially steam condensing or hot oil systems. Application: Boiler, heat exchanger, super heater, feedwater heater, condenser. Thïs model is selected when differential expansion makes a fixed tube sheet exchanger unsuitable and when conditions preclude a floating head type (HPF) selection.

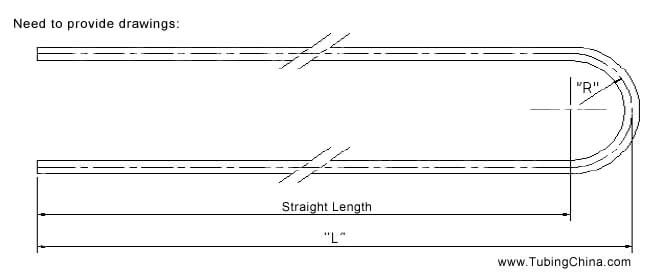

Dimensional tolerances U Bend Tube acc. to TEMA R.C.B. Dimensional tolerances U Bend Tube acc. to TEMA R.C.B.

1) U Bend Pipe Length of straight part -0/+5 mm

Flattening (also called “ovality”) at the bend shall not exceed 10% of the nominal tube outside diameter.

Wall thickness in bending part acc. to TEMA R.C.B 2.31

2) U Bend Tube Minimum tube wall thickness in the bend part (T min)T(min) ≥ (SW × (2×R + D))/( 2× (R+D)

where: SW is smallest wall thickness

D Nominal outside diameter

R radius

3) U Bend Tube Radius tolerance

1) for R 100 mm +/- 3 mm

2) for R ≥ 100 mm +/- 5 mm

4). U bend Pipe Straightness tolerance max. 1,5 mm per 1 m

U Bend Tube ends: plain, vertically cut to the tube axis

U Bend Tube OD in mm can be bent upon agreement: 15.8 16.0 17.0 18.0 19.05 20.0 21.3 25.4 26.7 31.8 32.0 38.1mm

U bend Tube Initial Length

Maximum lengths of 27000mm can be supplied on request

U bend Pipe Bending radius

Minimum: 1.5×OD

Maximum: 1500 mm

The dimensions for heat exchanger tube in special grades may differ from the above,please contact us.

U Bend Tube Main Testing Terms and Procedure:

1. Heat Treatment and Solution Annealing / Bright Annealing

2. Cutting to required length and deburring;

3. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

4. Visual Test and Endoscope Test for Surface Quality Test

5. 100% Hydrostatic Test and 100% Eddy Current Test

6. Ultrasonic Test subject to the MPS (Material Purchase Specification)

7. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

8. Impact Test subject to Standard request

9. Grain Size Test and Intergranular Corrosion Test

10. Ultrasoic measuring of Wall Thickness

11. Stress Relieve Annealing on U bend Parts after bending

U Bend Pipe Other details:

a. All tubes are cut to the specified leg lengths and internally cleaned with air, ends are deburred.

b. Before packing, both ends of U-bends are capped with plastic caps.

c. Vertical separators for each radius.

d. Packing lists, covered with plastic, are placed on each plywood case for easy identification of order details, including exact list of radius and lengths inside.

| Material Designation |

Corresponding Material Symbol |

| GB/T8890 |

ASTM B111 |

BS2871 |

JIS H3300 |

DIN1785 |

| Copper-Nickel |

BFe10-1-1 |

C70600 |

CN102 |

C7060 |

CuNi10Fe1Mn |

| BFe30-1-1 |

C71500 |

CN107 |

C7150 |

CuNi30Mn1Fe |

| (BFe30-2-2) |

C71640 |

CN108 |

C7164 |

CuNi30Fe2Mn2 |

| (BFe5-1.5-0.5) |

C70400 |

– |

– |

– |

| B7 |

– |

– |

– |

– |

| Aluminium Brass |

HAL77-2 |

C68700 |

CZ110 |

C6870 |

CuZn20Al2 |

| Admiralty Brass |

HSn70-1 |

C44300 |

CZ111 |

C4430 |

CuZn28Sn1 |

| Boric Brass |

Hsn70-18 |

– |

– |

– |

– |

| HSn70-1 AB |

– |

– |

– |

– |

| Arsenical Brass |

H68A |

– |

CZ126 |

– |

– |

| Brass Tubes |

H65/H63 |

C28000/C27200 |

CZ108 |

C2800/C2700 |

CuZn36/CuZn37 |

ASTM B111 Chemical Composition

| Designation |

Chemical Composition % |

| Cu |

Sn |

Al |

As |

Ni |

Fe |

Mn |

Pb

Max. |

Zn |

| C44300 |

70.0-73.0 |

0.9-1.2 |

– |

0.02-0.06 |

– |

0.06Max |

– |

0.07 |

Rem |

| C68700 |

76.0-79.0 |

– |

1.8-2.5 |

0.02-0.06 |

– |

0.06Max |

– |

0.07 |

Rem |

| C70400 |

Rem |

– |

– |

– |

4.8-6.2 |

1.3-1.7 |

0.3-0.8 |

0.05 |

1.0Max |

| C70600 |

Rem |

– |

– |

– |

9.0-11.0 |

1.0-1.8 |

1.0Max |

0.05 |

1.0Max |

| C71500 |

Rem |

– |

– |

– |

29.0-33.0 |

0.4-1.0 |

1.0Max |

0.05 |

1.0Max |

| C71640 |

Rem |

– |

– |

– |

29.0-32..0 |

1.7-2.3 |

1.5-2.5 |

0.05 |

1.0Max |

Brass Seamless Tubes Standard Specification:

| COUNTRY |

STANDARD |

NAME |

| ASTM |

ASTM B111 |

Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock |

| GB/T |

GB/T8890 |

Seamless Copper Alloy Heat Exchanger Tubes |

| BS |

BS2871 |

Copper and Copper Alloys Tubes |

| JIS |

JIS H3300 |

Copper and Copper Alloy-Seamless Pipes and Tubes |

| DIN |

DIN1785 |

Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers |

Standard Specification:

ASTM B111 Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock ASTM B111 Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

ASTM B395 Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes ASTM B395 Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

ASME SB466 Specification for Seamless Copper-Nickel Pipe and Tube ASME SB466 Specification for Seamless Copper-Nickel Pipe and Tube

BS 2871-2 Specification for copper and copper alloys. Tubes. Part 2: Tubes for general purposes BS 2871-2 Specification for copper and copper alloys. Tubes. Part 2: Tubes for general purposes

EN 12451 Copper and copper alloys - Seamless, round tubes for heat exchangers EN 12451 Copper and copper alloys - Seamless, round tubes for heat exchangers

DIN1785 Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers DIN1785 Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers

GB/T8890 Seamless Copper Alloy Heat Exchanger Tubes

JIS H3300 Copper and Copper Alloy-Seamless Pipes and Tubes

EEMUA 144 Specifications covering 90-10 Cu-Ni Piping for Offshore Applications are : Tubes Seamless and Welded Publication

EEMUA 234 UNS 7060X - 90/10 Copper nickel alloy piping for offshore applications (Incorporating EEMUA 144, 145 and 146)

DIN1785 Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers

EN 12451 CuNi10Fe1Mn CuZn20Al2As CuZn28Sn1As CuNi30Mn1Fe Copper and Copper Alloys Seamless Round Tubes for Heat Exchangers

DIN 86019 Seamless Tubes Made of CuNi10Fe1.6Mn for Pipes - Dimensions for Standard Tubes and Precision Tubes e

BS 2871 CN102 CN107 CN108 CZ110 CZ111 CZ126 CZ108 C101 C102 C106 Copper and Copper Alloy Tubes

Inch to mm Chart

Inches |

Decimal |

Millimeters |

1/16″ |

.0625 |

1.59 mm |

1/8″ |

.1250 |

3.18 mm |

3/16″ |

.1875 |

4.76 mm |

1/4″ |

.2500 |

6.35 mm |

5/16″ |

.3125 |

7.94 mm |

3/8″ |

.3750 |

9.53 mm |

7/16″ |

.4375 |

11.11 mm |

1/2″ |

.5000 |

12.70 mm |

9/16″ |

.5625 |

14.29 mm |

5/8″ |

.6250 |

15.88 mm |

11/16″ |

.6875 |

17.46 mm |

3/4″ |

.7500 |

19.05 mm |

13/16″ |

.8125 |

20.64 mm |

7/8″ |

.8750 |

22.23 mm |

15/16″ |

.9375 |

23.81 mm |

1″ |

1.00 |

25.40 mm |

1 1/4″ |

1.25 |

31.75 mm |

1 1/2″ |

1.50 |

38.10 mm |

2″ |

2.00 |

50.80 mm |

|