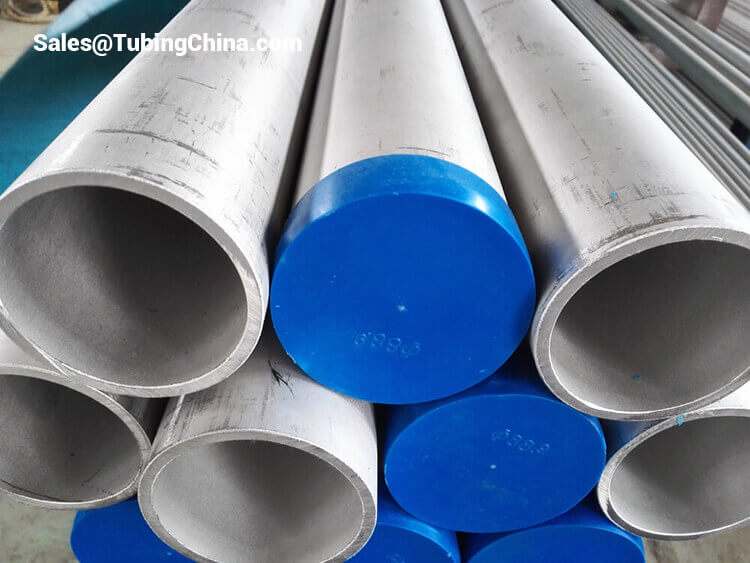

ASTM A312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe

OD: 17.15 - 508mm (3/8 INCH to 20 INCH)

WT: 0.5 - 60 mm, Schedule 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXH.

Production Capacity: 500 MT/Month

Guanyu Tube is specialized manufacturer of ASTM A312 TP304, ASTM A312 TP304L, ASTM A312 TP316, ASTM A312 TP316L, ASTM A312 TP321, ASTM A312 TP310S, ASTM A312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Supplier.

This is issued under the fixed designation ASTM A312; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon indicates an editorial change since the last revision or reapproval. This covers seamless, straight-seam and heavily cold worked welded austenitic stainless steel pipe for high-temperature and general corrosive service.

When the impact test criterion for a low-temperature service would be 15 ft·lbf [20 J] energy absorption or 15 mils [0.38 mm] lateral expansion, some of the austenitic stainless steel grades covered by this specification are accepted by certain pressure vessel or piping codes without the necessity of making the actual test. For example, Grades TP304, TP304L, and TP347 are accepted by the ASME Pressure Vessel Code, Section VIII Division 1, and by the Chemical Plant and Refinery Piping Code, ANSI B31.3, for service at temperatures as low as −425 °F [−250 °C] without qualification by impact tests.

Other AISI stainless steel grades are usually accepted for service temperature as low as −325 °F [−200 °C] without impact testing. Impact testing may, under certain circumstances, be required. For example, materials with chromium or nickel content outside the AISI ranges, and for material with carbon content exceeding 0.10 %, are required to be impact tested under the rules of ASME Section VIII Division 1 when service temperature are lower than −50 °F [−45 °C].

Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309Cb, TP309S, TP310Cb, TP310S, TP316, TP321, TP347, and TP348, and are intended for service at temperatures where creep and stress rupture properties are important.

Optional supplementary requirements are provided for pipe where a greater degree of testing is desired. These supplementary requirements call for additional tests to be made and, when desired, it is permitted to specify in the order one or more of these supplementary requirements.

Table X1.1 lists the standardized dimensions of welded and seamless stainless steel pipe as shown in ANSI B36.19. These dimensions are also applicable to heavily cold worked pipe. Pipe having other dimensions is permitted to be ordered

Nominal Pipe Size (NPS): 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, ... 20 inch

Outside Diameter: 10,3 - 508 mm (0,405 - 2,875 inch)

Wall Thickness: 0.5 - 63.5mm (0,02- 2 1/2 inch)

Notes:

Steel Grades - ASTM A312 TP304, ASTM A312 TP304L, ASTM A312 TP316, ASTM A312 TP316L, ASTM A312 TP321, ASTM A312 TP310S, ASTM A312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S

- Size of pipes in accordance with ANSI/ASME B36. 19M.

- All technical requirements in accordance with ASTM A530.

- Length tolerance of measured pipes is not greater than +10 mm.

- The quality of pipes is ensured by manufacturing process and non-destructive test.

- Intergranular corrosion test in accordance with ASTM A262, Practice E is available.

| ASTM A312 PIPE |

NB SIZES | SCH 5 | SCH 10 | SCH 40 | SCH 80 | SCH 160 | | Stainless Steel Pipe | 1/8″ | | | | | | | Stainless Steel Pipe | 1/4″ | | | | | | | Stainless Steel Pipe | 3/8″ | | | | | | | Stainless Steel Pipe | 1/2″ | | | | | | | Stainless Steel Pipe | 3/4″ | | | | | | | Stainless Steel Pipe | 1″ | | | | | | | Stainless Steel Pipe | 1 1/4″ | | | | | | | Stainless Steel Pipe | 1 1/2″ | | | | | | | Stainless Steel Pipe | 2″ | | | | | | | Stainless Steel Pipe | 2 1/2″ | | | | | | | Stainless Steel Pipe | 3″ | | | | | | | Stainless Steel Pipe | 4″ | | | | | | | Stainless Steel Pipe | 5″ | | | | | | | Stainless Steel Pipe | 6″ | | | | | |

ASTM A312 / A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe ASTM A312 / A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

ASME SA 312 / SA312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe ASME SA 312 / SA312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

ASTM A213 ASME SA213 TP304 TP304L TP309S TP310S TP316 TP316L TP316Ti TP321 TP317L TP347H Stainless Steel Heat Exchanger Tubes

ASTM A312 ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe

EN 10216-5 1.4301 1.4307 1.4948 1.4401 1.4404 1.4541 1.4571 1.4438 1.4841 1.4845 1.4539 Stainless Steel Tube Tubing

ASTM A789 ASME SA 789 S31803 S32205 S32101 S32750 S32760 S32304 S31500 S31260 Seamless Tubes

ASTM A790 ASME SA790 S31803 S32205 S32101 S32750 S32760 S32304 S31500 S31260 Seamless Pipe

EN 10216-5 1.4462 1.4362 1.4162 1.4410 1.4501 Seamless Tubes

Stainless Steel Pipe Specification:

Standard

Item |

ASTM A213 |

ASTM A269 |

ASTM A312 |

| Grade |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

Yield Strength

(Mpa) |

≥170;≥205 |

≥170;≥205 |

≥170;≥205 |

Tensile Strength

(Mpa) |

≥485;≥515 |

≥485;≥515 |

≥485;≥515 |

| Elongation(%) |

≥35 |

≥35 |

≥35 |

| Hydrostatic Test |

OD(mm) Pressure max

(MPa) |

OD(mm) Pressure max

(MPa) |

OD(mm) Pressure max

(MPa) |

|

D<25.4, 7Mpa |

D<25.4, 7Mpa |

D≤88.9, 17MPa |

|

25.4≤D<38.1, 10Mpa |

25.4≤D<38.1, 10Mpa |

|

|

38.1≤D<50.8, 14Mpa |

38.1≤D<50.8, 14Mpa |

|

|

50.8≤D<76.2, 17MPa |

50.8≤D<76.2, 17MPa |

D>88.9, 19MPa |

|

76.2≤D<127, 24MPa |

76.2≤D<127, 24MPa |

|

|

D≥127, 31Mpa |

D≥127, 31Mpa |

|

|

P=220.6t/D |

P=220.6t/D |

P=2St/D S=50%Rp0.2 |

| Intergranular Corrosion Test |

ASTM A262 E |

ASTM A262 E |

ASTM A262 E |

| Eddy Current Test |

ASTM E426 |

ASTM E426 |

ASTM E426 |

O.D. Tolerance

(mm) |

O.D. and

Tolerance |

O.D. and

Tolerance |

O.D. and

Tolerance |

|

D<25.4 +/-0.10 |

D<38.1 +/-0.13 |

10.3≤D≤48.3 +0.40/-0.80 |

| |

25.4≤D≤38.1 +/-0.15 |

|

|

| |

38.1<D<50.8 +/-0.20 |

38.1≤D<88.9 +/-0.25 |

48.3<D≤114.3 +0.80/-0.80 |

|

50.8≤D<63.5 +/-0.25 |

|

|

|

63.5≤D<76.2 +/-0.30 |

88.9≤D<139.7 +/-0.38 |

114.3<D≤219.1 +1.60/-0.80 |

|

76.2≤D≤101.6 +/-0.38 |

|

|

|

101.6<D≤190.5 +0.38/-0.64 |

139.7≤D<203.2 +/-0.76 |

219.1<D≤457.0 +2.40/-0.80 |

|

190.5<D≤228.6 +0.38/-1.14 |

|

|

W.T. Tolerance

(mm) |

O.D.

W.T.

Tolerance |

O.D.

W.T.

Tolerance |

O.D.

W.T.

Tolerance |

|

D≤38.1

WT +20%/-0 |

D<12.7

WT +/-15% |

10.3≤D≤73.0

WT +20.0%/-12.5% |

|

D>38.1

WT +22%/-0 |

12.7≤D<38.1

WT +/-10% |

88.9≤D≤457.0

t/D ≤5%

WT +22.5%/-12.5% |

|

|

D≥38.1

WT: +/-10% |

88.9≤D≤457.0

t/D >5%

WT +15.0%/-12.5% |

Sizes

|

OD, mm |

|

Max. Length, Meters |

1/8 |

10,3 |

1,73; 2,11 |

25 |

1/4 |

13,7 |

2,24; 3,02 |

25 |

3/8 |

17,1 |

2,31; 3,20 |

25 |

1/2 |

21,3 |

2,11; 3,73 |

25 |

3/4 |

26,7 |

2,87; 3,91 |

25 |

1 |

33,4 |

3,38; 4,55; 6,35 |

25 |

1 1/4 |

42,4 |

3,56; 4,85; 6,35 |

25 |

1 1/2 |

48,3 |

3,68; 5,03; 7,14 |

25 |

2 |

60,3 |

3,58; 3,91; 4,37; 4,78; 6,35; 6,94; 7,14 |

25 |

2 1/2 |

73,0 |

3,58; 3,95; 4,37; 4,78; 5,16; 5,49; 6,35; 7,01 |

25 |

Mechanical properties

Steel Grade |

|

|

Elongation, % (min) |

TP304 |

515 |

205 |

35 |

TP304L |

485 |

170 |

35 |

TP316 |

515 |

205 |

35 |

TP316L |

485 |

170 |

35 |

TP321 |

OD < 17,1 mm - 515;

OD > 17,1 mm - 485 |

OD < 17,1 mm - 205;

OD > 17,1 mm - 170 |

35 |

Chemical Composition (%, max)

Steel Grade |

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

TP304 |

0,08 |

0,75 |

2 |

18 - 20 |

8 - 11 |

- |

0,03 |

0,04 |

TP304L |

0,035 |

0,75 |

2 |

18 - 20 |

8 - 13 |

- |

0,03 |

0,04 |

TP316 |

0,08 |

0,75 |

2 |

16 - 18 |

11 - 14 |

2 - 3 |

0,03 |

0,04 |

TP316L |

0,035 |

0,75 |

2 |

16 - 18 |

10 - 15 |

2 - 3 |

0,03 |

0,04 |

TP321 |

0,08 |

0,75 |

2 |

17 - 20 |

9 - 13 |

- |

0,03 |

0,04 |

Difference Between ASTM A213 and ASTM A269

Difference Between ASTM A213 and ASTM A312

Difference Between ASTM A269 and ASTM A312

|