ASTM A262 Intergranular Corrosion Test IGC

Intergranular corrosion is sometimes also called "intercrystalline corrosion" or "interdendritic corrosion". In the presence of tensile stress, cracking may occur along grain boundaries and this type of corrosion is frequently called "interranular stress corrosion cracking (IGSCC)" or simply "intergranular corrosion cracking".

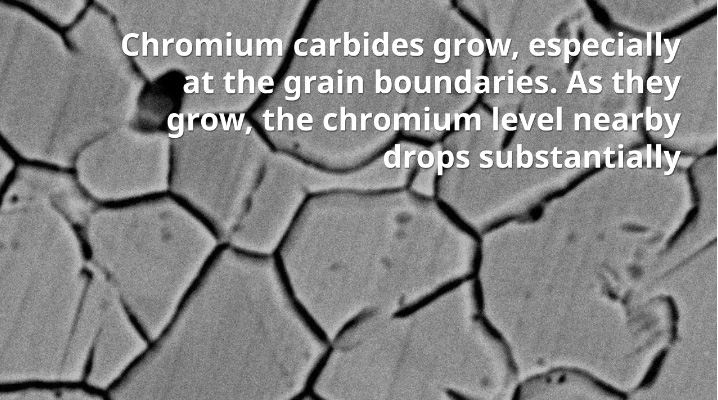

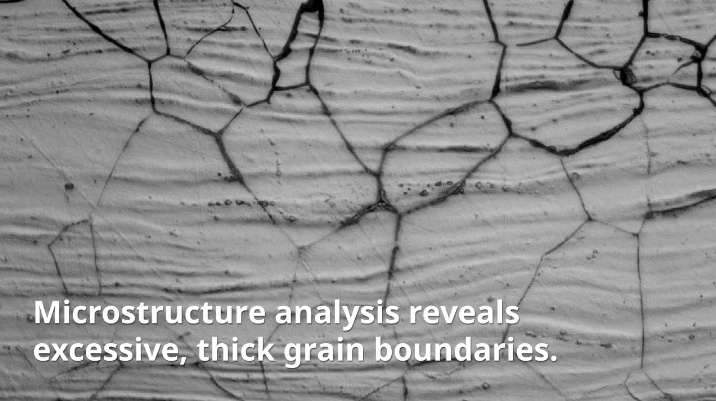

Intergranular corrosion in stainless steel may result from precipitation of carbides, nitrides or intermetallic phases. Only in the most highly oxidizing solutions can intergranular attack be caused by intermetallic phases. When a test is to be restricted to carbides, in a material containing nitrides or intermetallic phases, a less oxidizing solution is chosen.

The following tests are carried out by us as per the ASTM A262 specification.

Oxalic Acid Test, ASTM A262, Practice A (Oxalic Acid Etch)

The oxalic acid etch test is a rapid method of screening those specimens of certain stainless steel grades which are essentially free of susceptibility to intergranular attack associated with chromium carbide participates. The test is used for acceptance but not rejection of material.

Ferric Sulfate - Sulfuric Acid, ASTM A262 - Practice B (Streicher Test)

This test is based on weight loss determinations and provides a quantitative measure of the relative performance of the material evaluated. The procedure includes subjecting a specimen to a 24 to 120 hour boil in ferric sulfate - 50% sulfuric acid. This procedure measures the susceptibility of stainless steel and nickel alloys to inter granular attack associated with the precipitation of chromium carbides at grain boundaries.

Nitric Acid, ASTM A262, Practice C, (Huey Test)

The specimens are boiled for five periods, each of 48 hours, in a 65 per cent solution of nitric acid. The corrosion rate during each boiling period is calculated from the decrease in the weight of the specimens. Properly interpreted, the results can reveal whether or not the steel has been heat-treated in the correct manner. The customer must specify the maximum permissible corrosion rate and, in applicable cases, data on sensibilizing heat treatment.

The Huey test environment is strongly oxidizing, and, is only used as a check on whether the material has been correctly heat treated. This test is suitable for the detection of chromium depleted regions as well as intermetallic precipitations, like sigma phase, in the material. The Huey test is also used for materials that come into contact with strongly oxidising agents, e.g. nitric acid. This procedure may also be used to check the effectiveness of stabilizing elements and of reductions in carbon content in reducing susceptibility to inter granular attack in chromium-nickel stainless steel.

Copper - Copper Sulfate - 16% sulfuric acid, ASTM A262 - Practice E (Strauss Test)

This procedure is conducted to determine the susceptibility of austenitic stainless steel to inter granular attack associated with the precipitation of chromium-rich carbides. Once the specimen has been subjected to the solution boil, it is bent through 180° and over a diameter equal to the thickness of the specimen being bent. This test is based on a visual examination of the bent specimen.

Copper - Copper Sulfate - 50% sulfuric acid, ASTM A262 - Practice F

This test is based on weight loss determination which provides a quantitative measure of the relative performance of the material evaluated. It measures the susceptibility of "as received" stainless steels to inter granular attack.

Salt Spray (Neutral / Fog), ASTM B117

This is the most commonly used salt spray for testing of

inorganic and organic coatings, especially where such tests are

used for material or product specifications. Salt Spray testing

is a tool for evaluation the uniformity of thickness and degree

of porosity of metallic and nonmetallic protective coatings. A

number of samples can be tested at once depending upon their

size CASS Test, tarnishing test are also done.

Pitting Corrosion Test, ASTM Gr 48

This Procedure is used to assist in the selection of test

methods that can be used in the identification and examination

of pits and in the evaluation of pitting corrosion to determine

the extent of its effect. The importance of this evaluation is

to be able to determine the extent of pitting, either in a

service application where it is necessary to predict the

remaining life in a metal structure, or in laboratory test

programs that are used to select the most pitting-resistant

materials for service. ASTM Gr 48 Method A and ASTM A923 Method

C are typical pitting corrosion tests performed.

Hydrogen-Induced Cracking (HIC) Test, NACE TMO284

This test method evaluates the resistance of pipeline and

pressure vessel plate steels to Hydrogen Inducted Cracking

caused by hydrogen absorption from aqueous sulfide corrosion. An

unstressed test specimen is exposed to a solution at ambient

temperature and pressure and after a specified time, the test

specimen is removed and evaluated.

Sulfide Stress Corrosion Cracking (SSCC), NACE TM 0177

The polythionic acid (sulfurous acid and hydrogen sulfide)

environment provides a way of evaluating the resistance of

stainless steels and related alloys to inter-granular stress

corrosion cracking. This practice can be applied to wrought

products, castings, weld metal of stainless steels or other

materials to be used in environments containing sulfur or

sulfides

Chloride Stress Corrosion Test as per ASTM Gr 36 Specification

ASTM A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels ASTM A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

Corrosion | Metallographic Test | Metallographic Test Report | Stress Corrosion Cracking | Chloride SCC | Minimizing Chloride SCC | Stainless Steel Corrosion | Intergranular Corrosion | Stainless Steel Intergranular Corrosion | Corrosion of Piping Corrosion Resistant Stainless Steel | Corrosion Resistant Material | Corrosion Resistance | Seawater Resistance

Corrosion Mechanism | Corrosion Process | Surface Coatings for Corrosion | Galvanic Corrosion | Galvanic Corrosion Risks Causes of Metal Corrosion | Stainless Steel for Corrosion Resistance | ASTM A262 | ASTM E112 | Corrosion Resistance Table | Metals Corrosion Resistance | Oxidation Resistance | NACE MR0175/ISO 15156 | Carbon on Corrosion Resistance

Metallographic Test - Metallography Testing

Metallographic Test Report

Stress Corrosion Cracking (SCC)

Chloride Stress Corrosion Cracking

Stainless Steel Corrosion

Intergranular Corrosion

Intergranular Corrosion of Stainless Steel Tubes

Corrosion Resistant Stainless Steel Tube

Corrosion Resistance of Stainless Steel Tubes

Seawater Resistance of Stainless Steel Tubes

Corrosion Mechanism in Stainless Steel Tube

ASTM A262 Intergranular Corrosion Test IGC

ASTM E112 Standard Test Methods for Determining Average Grain Size

Methods of minimizing chloride stress corrosion cracking

|