The corrosion rate of in

sulfuric acid is negligible in any concentration from 0 to 99% up to a temperature of at least 150°C. In

sulfuric acid at temperatures above 150°C the corrosion rate will have to be considered, but the corrosion rate in high temperature sulfuric acid is magnitudes lower than the corrosion rates of

Hastelloy,

titanium and zirconium.

Corrosion in diluted Sulfuric Acid (0-10%)

In diluted sulfuric acid (less than 10% sulfuric acid) the aggressiveness of the acid is limited, so

austenitic and

duplex steel and to some extend titanium may be a cost efficient option in the low temperature range. At temperatures above 100C more corrosion resistant materials like

Hastelloy grades may be required.

Corrosion in Sulfuric Acid in the Concentration Range 10% to 90%

Sulfuric Acid in concentrations between 10 and 90% is known to be especially corrosive. Common type specialty metals like e.g. titanium and

Hastelloy c-276 will show rapid corrosion in sulfuric acid at temperature lower than 100 C. Very few materials including exotic metals like Zirconium and

Tantalum materials can be applied above the sulfuric acid boiling point. Tantaline is by far the most economical option. Tantaline will further maintain its corrosion resistance above the boiling point independent on the concentration up to 99%, whereas Zirconium will lose its

corrosion resistance in sulfuric acid at concentration above approximately 75%.

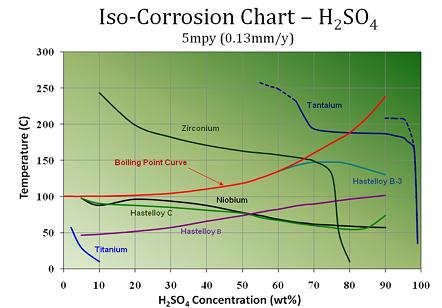

Sulfuric Acid Iso Corrosion Curves

This iso corroion curve shows the relative

corrosion resistance of several specialty alloys and exotic metals in various concentrations and temperatures of sulfuric (sulphuric) acid (H2SO4). It can be seen that the corrosive nature of

sulfuric acid, as with most acids, is highly dependent on the

temperature and concentration of the solution.

Corrosion in Concentrated Sulfuric Acid

Concentrated sulfuric acid (water free) sulfuric acid is less corrosive than water containing sulfuric acid and iron based alloys can shows in general good

corrosion resistance in concentrated sulfuric acid. Silicon cast iron show low corrosion rates in 99% sulfuric acid, but will suffer from

stress corrosion cracking when in SO3 containing concentrated sulfuric acid (oleum). Depending on temperature

austenitic stainless steel can be applied in oleum.

Material performance in Sulphuric acid, H2SO4

| Conc. % |

20 |

20 |

20 |

20 |

30 |

30 |

30 |

30 |

40 |

40 |

40 |

40 |

50 |

50 |

50 |

| Temp. °C |

50 |

60 |

80 |

100 |

20 |

40 |

60 |

80 |

20 |

40 |

60 |

90 |

20 |

40 |

70 |

| Grade or type of alloy: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Carbon steel |

2 |

2 |

|

2 |

2 |

2 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 13 Cr |

2 |

2 |

|

2 |

2 |

2 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 304/304L |

2 |

2 |

|

2 |

2 |

2 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| TP316/316L |

1 |

2 |

|

2 |

1 |

2 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 18Cr13Ni3Mo/317L |

1 |

1 |

|

2 |

1 |

1 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 17Cr14Ni4Mo / 1.4439 |

1 |

1 |

|

2 |

1 |

1 |

2 |

|

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 904L / N08904 |

0 |

0 |

1 |

2 |

0 |

0 |

1 |

|

0 |

0 |

1 |

2 |

0 |

0 |

2 |

| Sanicro 28 |

0 |

0 |

|

2 |

0 |

0 |

1 |

|

0 |

0 |

1 |

2 |

0 |

0 |

1 |

| 254 SMO |

0 |

0 |

|

2 |

0 |

0 |

1 |

2 |

|

1 |

|

|

0 |

1 |

|

| 654 SMO |

0 |

0 |

0 |

2 |

|

|

|

|

0 |

0 |

0 |

|

0 |

0 |

|

| SAF 2304 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| SAF 2205 |

0 |

1 |

2 |

2 |

0 |

1 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| SAF 2507 |

0 |

0 |

|

|

|

0 |

1 |

|

0 |

|

|

2 |

|

|

2 |

| Titanium (CP Ti) |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| SAF 2906 |

|

|

0 |

2 |

|

|

|

2 |

|

0 |

2 |

|

2 |

2 |

|

| SAF 2707 HD |

|

|

0 |

2 |

|

|

|

2 |

|

0 |

0 |

|

2 |

2 |

|

| SAF 3207 HD |

|

|

0 |

2 |

|

|

|

2 |

|

0 |

0 |

|

0 |

2 |

|

|

| Conc. % |

60 |

60 |

60 |

70 |

70 |

70 |

80 |

80 |

80 |

85 |

85 |

85 |

85 |

90 |

90 |

| Temp. °C |

20 |

40 |

70 |

20 |

40 |

70 |

20 |

40 |

60 |

20 |

30 |

40 |

50 |

20 |

30 |

| Grade or type of alloy: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Carbon steel |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

0 |

1 |

2 |

2 |

0 |

1 |

| 13 Cr |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

1 |

2 |

2 |

0 |

1 |

| 304/304L |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

1 |

1 |

2 |

0 |

0 |

| TP316/316L |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

2 |

2 |

1 |

1 |

1 |

2 |

0 |

0 |

| 18Cr13Ni3Mo/317L |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

2 |

2 |

1 |

1 |

1 |

2 |

0 |

1 |

| 17Cr14Ni4Mo / 1.4439 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

2 |

2 |

1 |

1 |

1 |

2 |

0 |

1 |

| 904L / N08904 |

0 |

1 |

1 |

0 |

1 |

1 |

0 |

1 |

2 |

0 |

0 |

1 |

1 |

0 |

0 |

| Sanicro 28 |

0 |

0 |

1 |

0 |

0 |

1 |

|

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

| 254 SMO |

0 |

1 |

|

0 |

1 |

|

0 |

1 |

2 |

0 |

|

|

|

1 |

|

| 654 SMO |

0 |

1 |

|

0 |

1 |

|

|

|

|

|

|

|

|

1 |

|

| SAF 2304 |

2 |

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

1 |

| SAF 2205 |

2 |

2 |

2 |

1 |

|

|

2 |

2 |

2 |

1 |

|

|

|

1 |

1 |

| SAF 2507 |

|

|

|

0 |

2 |

2 |

2 |

|

2 |

1 |

1 |

1 |

|

0 |

0 |

| Titanium (CP Ti) |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| SAF 2906 |

|

|

|

0 |

|

|

1 |

2 |

|

|

|

1 |

|

|

|

| SAF 2707 HD |

|

|

|

1 |

|

|

2 |

2 |

|

|

|

1 |

|

|

|

| SAF 3207 HD |

|

|

|

0 |

|

|

2 |

2 |

|

|

|

1 |

|

|

| Conc. % |

90 |

90 |

94 |

94 |

94 |

94 |

96 |

96 |

96 |

96 |

98 |

98 |

98 |

98 |

| Temp. °C |

40 |

70 |

20 |

30 |

40 |

50 |

20 |

30 |

40 |

50 |

30 |

40 |

50 |

80 |

| Grade or type of alloy: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Carbon steel |

2 |

2 |

0 |

2 |

2 |

2 |

0 |

1 |

2 |

2 |

1 |

1 |

2 |

2 |

| 13 Cr |

2 |

2 |

0 |

1 |

2 |

2 |

0 |

1 |

2 |

2 |

1 |

1 |

2 |

2 |

| 304/304L |

2 |

2 |

0 |

0 |

1 |

1 |

0 |

0 |

0 |

1 |

0 |

0 |

2 |

2 |

| TP316/316L |

1 |

2 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

2 |

| 18Cr13Ni3Mo/317L |

1 |

2 |

0 |

0 |

1 |

1 |

0 |

0 |

1 |

1 |

0 |

0 |

1 |

2 |

| 17Cr14Ni4Mo / 1.4439 |

1 |

2 |

0 |

0 |

1 |

1 |

0 |

0 |

1 |

1 |

0 |

0 |

1 |

2 |

| 904L / N08904 |

1 |

2 |

0 |

0 |

1 |

1 |

0 |

0 |

1 |

1 |

0 |

1 |

1 |

2 |

| Sanicro 28 |

0 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

| 254 SMO |

1 |

|

|

|

|

|

1 |

|

|

|

|

|

0 |

2 |

| 654 SMO |

2 |

2 |

|

|

|

2 |

0 |

1 |

|

2 |

|

|

1 |

1 |

| SAF 2304 |

1 |

|

|

|

|

|

1 |

|

|

0 |

|

|

0 |

1 |

| SAF 2205 |

1 |

|

0 |

|

|

|

0 |

0 |

1 |

|

0 |

0 |

1 |

1 |

| SAF 2507 |

0 |

2 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

| Titanium (CP Ti) |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| SAF 2906 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

| SAF 2707 HD |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

| SAF 3207 HD |

|

2 |

|

| Conc. H2SO4 % |

100 |

100 |

100 |

100 |

100 |

100 |

| Conc. SO3 % |

7 |

11 |

11 |

60 |

60 |

60 |

| Temp. °C |

60 |

60 |

100 |

20 |

70 |

80 |

| Grade or type of alloy: |

|

|

|

|

|

|

| Carbon steel |

0 |

0 |

2 |

|

|

|

| 13 Cr |

0 |

0 |

2 |

|

|

2 |

| 304/304L |

0 |

0 |

1 |

0 |

0 |

0 |

| TP316/316L |

0 |

0 |

0 |

0 |

0 |

0 |

| 18Cr13Ni3Mo/317L |

0 |

0 |

|

0 |

0 |

|

| 17Cr14Ni4Mo / 1.4439 |

0 |

0 |

|

0 |

0 |

|

| 904L / N08904 |

0 |

0 |

|

0 |

0 |

|

| Sanicro 28 |

|

|

|

|

|

|

| 254 SMO |

|

|

|

|

|

|

| 654 SMO |

|

|

|

|

|

|

| SAF 2304 |

|

|

|

|

|

|

| SAF 2205 |

|

|

|

|

|

|

| SAF 2507 |

|

|

|

|

|

|

| Titanium (CP Ti) |

2 |

2 |

2 |

2 |

2 |

2 |

Symbol clarification

These corrosion tables use a number of symbols, having the following meanings:

| Symbol |

Description |

| 0 |

Corrosion rate less than 0.1 mm/year. The material is corrosion proof. |

| 1 |

Corrosion rate 0.1—1.0 mm/year. The material is not corrosion proof, but useful in certain cases. |

| 2 |

Corrosion rate over 1.0 mm/year. Serious corrosion. The material is not usable. |

| p, P |

Risk (severe risk) of pitting and crevice corrosion. |

| c, C |

Risk (Severe risk) of crevice corrosion. Used when there is a risk of localised corrosion only if crevices are present. Under more severe conditions, when there is also a risk of pitting corrosion, the symbols p or P are used instead. |

| s, S |

Risk (Severe risk) of stress corrosion cracking. |

| ig |

Risk of intergranular corrosion. |

| BP |

Boiling solution. |

| ND |

No data. (Used only where there are no actual data to estimate the risk of localised corrosion instead of p or s). |

Sulfuric Acid Corrosion Tables

Table: Corrosion Performance and Relative Cost of Materials in Sulfuric Acid at Concentrations from 10 to 90% and Temperatures of 50°C, 100°C and 150°C

Performance/ Price Ratio of Materials for Sulfuric Acid service

Offers a chemical performance equal to tantalum at prices similar to nickel alloys having an absolutely unique performance/cost ratio compared to other solutions in titanium, nickel alloys, zirconium and tantalum. As can be seen from the table above Tantaline has superior performance over niobium, zirconium and nickel based alloys at a lower relative price.

Solutions for Sulfuric Acid Service

A large heater services have been installed in plants for the re-concentration of diluted sulphuric acid arising from metal pickling, oil refinery operations and from petrochemical processes producing alcohols and ketones.

Limitation of Sulfuric Acid Service

At very high concentrations of sulfuric acid (>98%), the corrosion performance of tantalum will decrease due to existence of "free" SO3. Thus Tantalum metal is in general not suitable for fuming sulfuric acid (oleum).