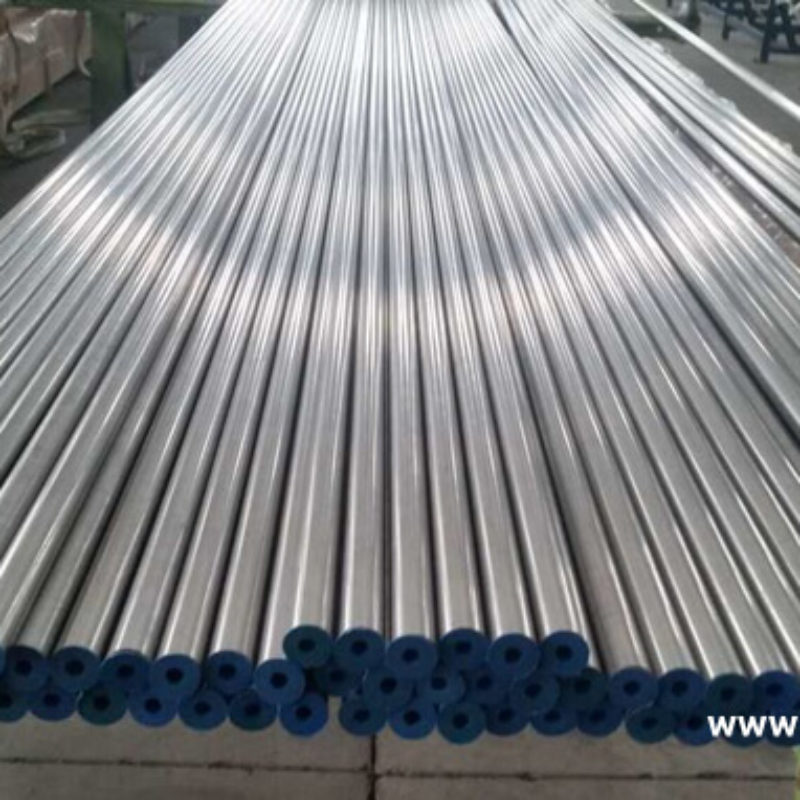

Incoloy Tubes Incoloy Alloy Tubing

Incoloy alloy is applied as the prefix name to several highly corrosion resistant high temperature strength metal alloys produced by Special Metals Corporation. These Incoloy alloys or superalloys are nickel-based alloys that exhibit traits that include good corrosion resistance in aqueous environments, excellent strength and oxidation resistance in high-temperature settings, good creep-rupture strength, and ease of fabrication.

Alloys of identical chemical and mechanical properties are available from other manufacturers and offer excellent alternatives to the various Incoloy brand alloys. The corrosion-resistant superalloys are widely used in extreme environments where tremendous heat and corrosion resistance is paramount to the integrity of the end product. Chemical and petrochemical processing, power plants, and oil and gas industries widely use these superalloys.

Mega Mex supplies Incoloy 800, 800H/800HT and 825 in the form of plate, sheet, strip, bar, wire, pipe, tubing, pipe fittings, and flanges.

Incoloy alloy application:

- Process piping, heat exchangers, carburizing equipment, heating-element sheathing, nuclear steam-generator tubing

- Chemical and petrochemical processing, power plants, industrial furnaces, heat-treating equipment

- Pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, pickling equipment

What are the Characteristics of Incoloy?

- Good corrosion resistance in aqueous environments

- Excellent strength resistance in high-temperature settings

- Excellent oxidation and carburization resistance in high-temperature settings

- Good creep-rupture strength

- Ease of fabrication

Incoloy Alloy Specification:

ASME SB163 Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

ASME SB165 Standard Specification for Nickel-Copper Alloy (UNS N04400)* Seamless Pipe and Tube

ASME SB167 Standard Specification for Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617),and Nickel-Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipe and Tube

ASME SB407 Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

ASME SB423 Standard Specification for Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825, N08221, and N06845) Seamless Pipe and Tube

ASME SB444 Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube

ASME SB622 Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

ASME SB668 UNS N08028 Seamless Pipe and Tube

ASME SB690 Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Seamless Pipe and Tube

ASME SB729 Standard Specification for seamless UNS N08020, UNS N08026, and UNS N08024 nickel alloy pipe and Tube

Superalloys, also known as high performance alloys, have become the steel of choice for corrosion resistance and versatility.

ickel Alloy Tubing Grade Comparion Chart

| China GB | Unified Digital Code | ASTM | UNS Code | EN Code | Company Commercial Grade |

|---|---|---|---|---|---|

| Ni68Cu28Fe | – | 400 | N04400 | 2.4360 | Monel 400(SMC) |

| – | – | K500 | N05500 | 2.4375 | Monel K500(SMC) |

| 1Cr15Ni75Fe | NS3102 | 600 | N06600 | 2.4816 | Inconel 600(SMC) |

| 1Cr23Ni60Fe13Al | NS3103 | 601 | N06601 | 2.4851 | Inconel 601(SMC) |

| 20Cr25Ni60Fe10AlY | – | 602 | N06025 | 2.4633 | Nicrofer 6025HT(VDM) |

| – | – | 617 | N06617 | 2.4663 | Inconel 617(SMC) |

| 0Cr20Ni65Mo10Nb4 | NS3306 | 625 | N06625 | 2.4856 | Inconel 625(SMC) |

| 0Cr30Ni60Fe10 | NS3105 | 690 | N06690 | 2.4642 | Inconel 690(SMC) |

| 0Cr20Ni32AlTi | NS1101 | 800 | N08800 | 1.4876 | Incoloy 800(SMC) |

| 1Cr20Ni32AlTi | NS1102 | 800H | N08810 | 1.4958 | Incoloy 800H(SMC) |

| 1Cr20Ni32AlTi | NS1102 | 800HT | N08811 | 1.4959 | Incoloy 800HT(SMC) |

| 0Cr21Ni42Mo3Cu2Ti | NS1402 | 825 | N08825 | 2.4858 | Incoloy 825(SMC) |

| 00Cr15Ni60Mo16W5Fe5 | NS3304 | C276 | N10276 | 2.4819 | Hastelloy C276(Haynes) |

| 00Cr17Ni57Mo13W3 | NS3308 | C22 | N06022 | 2.4602 | Hastelloy C22(Haynes) |

| – | NS3405 | C2000 | N06200 | 2.4675 | Hastelloy C2000(Haynes) |

| 00Ni70Mo28 | NS3202 | B2 | N10665 | 2.4617 | Hastelloy B2(Haynes) |

| 00Mo28Ni65Fe1.5Cr1.5 | NS3203 | B3 | N10675 | 2.4600 | Hastelloy B3(Haynes) |

| 0Cr20Ni35Mo3Cu3Nb | NS1403 | Alloy 20 | N08020 | 2.4660 | Incoloy 020(SMC) |

| 00Cr27Ni31Mo3Cu | – | Alloy 28 | N08028 | 1.4563 | Sanicro 28 |

| 00Cr27Ni31Mo7CuN | NS1404 | Alloy 31 | N08031 | 1.4562 | Nicrofer 3127hMo(VDM) |

| 00Cr22Ni48Mo7Cu2Nb | NS3403 | G3 | N06985 | 2.4619 | Hastelloy G3(Haynes) |

| 00Cr30Ni43Mo5.5W2.5Cu2Nb | NS3404 | G30 | N06030 | 2.4603 | Hastelloy G30(Haynes) |

| 0Cr33Ni55Mo8 | – | G35 | N06035 | 2.4643 | Hastelloy G35(Haynes) |

| 0Cr15Ni70Ti3AlNb | GH4145 | X750 | N07750 | 2.4669 | Inconel X750(SMC) |

- Incoloy Alloy Tubing

- A286 Nickel Alloy Tubing

- Nickel Alloy 20 N08020 Nickel Alloy Tubing Tubes Pipe

- Incoloy 800 N08800 Alloy Tubing Tubes Pipe

- Incoloy 800H N08810 Alloy Tubing Tubes Pipe

- Incoloy 800HT N08811 Alloy Tubing Tubes Pipe

- Incoloy 825 Pipe, N08825 Alloy Pipe

- Incoloy 901 N09901 Nickel Alloy Tubing Tubes Pipe

- Incoloy 925 N09925 Nickel Alloy Tubing Tubes Pipe

- Incoloy 926 N08926 Nickel Alloy Tubing Tubes Pipe Stockholder

- Inconel Alloy Tubing

- Inconel 600 N06600 Nickel Alloy Tubing Tubes Pipe

- Inconel 601 N06601 Nickel Alloy Tubing Tubes Pipe

- Inconel 625 N06625 Nickel Alloy Tubing Tubes Pipe

- Inconel 706 N09706Nickel Alloy Tubing Tubes Pipe

- Inconel 718 N07718 Nickel Alloy Tubing Tubes Pipe

- Inconel X-750 N07750 Nickel Alloy Tubing Tubes PipeHastelloy Alloy Tubing

- Hastelloy B N10001 Nickel Alloy Tubing Tubes Pipe Manufacturer

- Hastelloy B2 N10665 Nickel Alloy Tubing Tubes Pipe

- Hastelloy B3 N10675 Nickel Alloy Tubing Tubes Pipe Supplier

- Hastelloy C4 N06455 Nickel Alloy Tubing Tubes Pipe

- Hastelloy C22 N06022 Nickel Alloy Tubing Tubes Pipe Supplier

- Hastelloy C276 ASTM B622 N10276 Nickel Alloy Tubing Tubes Pipe

- Hastelloy X N06002 Nickel Alloy Tubing Tubes Pipe Factory

- Hastelloy G Nickel Alloy Tubing Tubes Pipe

- Hastelloy G3 N06985 Nickel Alloy Tubing Tubes Pipe

- Nimonic Alloy Tubing

- Nimonic 75 N06075 Alloy Tubing Tubes Pipe

- Nimonic 80A N07080 Alloy Tubing Tubes Pipe

- Nimonic 90 N07090 Alloy Tubing Tubes Pipe Suppliers

- Monel Nickel Alloy Tubing

- Alloy 200 N02200 Nickel Alloy Tubing Tubes Pipe

- Alloy 201 N02201 Nickel Alloy Tubing Tubes Pipe

- Monel 400 Tubing

- Monel 401 N04401 Nickel Alloy Tubing Tubes Pipe Manufacturer

- Monel R 405 N04405 Nickel Alloy Tubing Tubes Pipe

- Monel K 500 N05500 Nickel Alloy Tubing Tubes Pipe Exporter