ASTM B444 Nickel Alloys Tubes Pipes UNS6625 UNS6852

ASTM B444 covers nickel-chromiummolybdenum-columbium alloys (UNS N06625 and UNS

N06852) and nickel-chromium-molybdenum-silicon alloy (UNS N06219)* in the form of cold-worked seamless pipe and tube. The general requirements for pipe and tube are covered by Specification B 829.

1.1.1 UNS N06625 products are furnished in two grades of different heat-treated conditions:

1.1.1.1 Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C).

1.1.1.2 Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

NOTE 1—Hot-working or reannealing may change properties significantly, depending on working history and temperatures.

1.1.2 Alloys UNS N06219 and UNS N06852 are supplied in the solution annealed condition only.

1.2 The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

ASTM B829 Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

3. General Requirement

3.1 Material furnished under this specification shall conform to the applicable requirements of Specification ASTM B829 unless otherwise provided herein.

4. Ordering Information

4.1 Orders for material to this specification shall include information with respect to the following:

4.1.1 Alloy name or UNS number,

4.1.2 ASTM designation,

4.1.3 Condition (temper) (see 1.1.1, 1.1.2, Section 6, and Appendix X1 and Appendix X2),

4.1.3.1 If neither grade of N06625 is specified, Grade 1 will be supplied.

4.1.4 Finish (See Appendix X2),

4.1.5 Dimensions:

4.1.5.1 Tube—Specify outside diameter and nominal or minimum wall,

4.1.5.2 Pipe—Specify standard pipe size and schedule,

4.1.5.3 Length—Cut to length or random,

4.1.6 Quantity—Feet (or metres) or number of pieces,

4.1.7 Hydrostatic Test or Nondestructive Electric Test—Specify type of test (see 6.2),

4.1.8 Hydrostatic Pressure Requirements—Specify test pressure if other than required by 9.1.1,

4.1.9 Certification—State if certification is required,

4.1.10 Samples for Product (Check) Analysis—State whether samples for product (check) analysis should be furnished

4.1.11 Purchaser Inspection—If purchaser wishes to witness tests or inspection of material at place of manufacture, the purchase order must so state indicating which tests or inspections

are to be witnessed, and

4.1.12 Small-Diameter and Light-Wall Tube (Converter Sizes)—See Appendix X1 and Table 1.

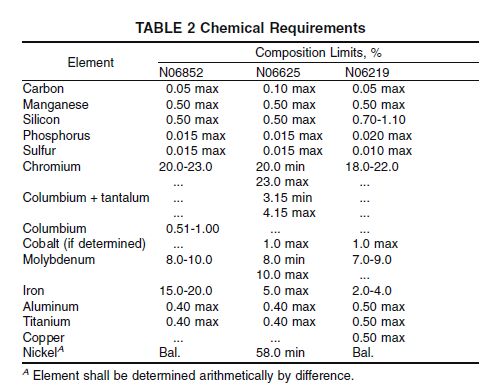

5. Chemical Composition

5.1 The material shall conform to the composition limits specified in Table 2. One test is required for each lot as defined in Specification B 829.

5.2 If a product (check) analysis is performed by the purchaser, the material shall conform to the product (check) analysis variations in Table 2 of Specification B 829.

A Element shall be determined arithmetically by difference.

6. Mechanical Properties and Other Requirements

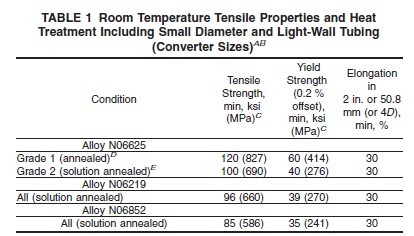

6.1 Tension Test— The material shall conform to the tensile strength properties specified in Table 1. The sampling and specimen preparation are as covered in Specification B 829.

6.2 Hydrostatic or Nondestructive Electric Test—Each pipe or tube shall be subjected to either the hydrostatic test or to the nondestructive electric test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the purchase order.

A Not applicable to outside diameters under 1⁄8 in. (3.2 mm) and to wall thicknesses under 0.015 in. (0.38 mm).

B Hot forming quality pipe and tubing is furnished to chemical requirements and surface inspection only. No tensile properties are required.

C The minimum strength values apply only to tubing in straight lengths.

D Annealed at 1600°F (871°C) minimum.

E Solution annealed at 2000°F (1093°C) minimum, with or without subsequent stabilization anneal at 1800°F (982°C) minimum to increase resistance to sensitization.

7. Dimensions and Permissible Variations

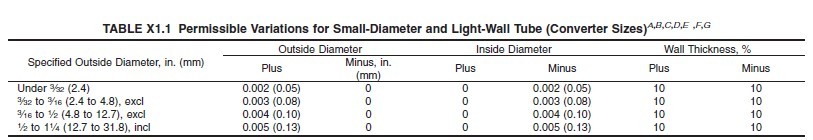

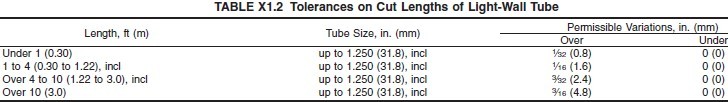

7.1 Permissible variations for material specified as smalldiameter and light-wall tube (converter size) shall conform to the permissible variations prescribed in Table X1.1 and Table

X1.2.

A Ovality, Normal-Wall Tube—Ovality will be held within 2 % of the theoretical average outside diameter.

B Ovality, Light-Wall Tube—Ovality will be held within 3 % of the theoretical average outside diameter.

C Wall Tolerances, Light-Wall Tube—The plus and minus wall tolerance shown in the table shall apply down to and including 0.005 in. (0.13 mm) in wall thickness. For wall thicknesses less than 0.005 in. (0.13 mm), the tolerance shall be 60.0005 in. (0.013 mm).

D Random Lengths:

Where nominal random lengths on tubing 1⁄8 in. (3.2 mm) and larger in outside diameter are specified, a length tolerance of 631⁄2 ft (1.07 m) applies to the nominal length. This is a total spread of 7 ft (2.13 m).

Random lengths in sizes 1⁄8 in. (3.2 mm) and larger in outside diameter shall be subject to a length range of 5 to 24 ft (1.52 to 7.32 m). Long random lengths are subject to a range from 15 to 22 ft (4.57 to 6.71 m).

Random lengths in sizes up to, but not including 1⁄8 in. (3.2 mm) in outside diameter, and fragile light-wall tubes over this outside diameter are subject to the length range from 1 to 15 ft (0.30 to 4.57 m).

E Cut Lengths—Tolerances on cut lengths shall be in accordance with Table X1.1.

FStraightness—Round tubing is subject to a straightness tolerance of 1 part in 600 [equivalent to a depth of arc of 0.030 in. (0.76 mm) in any 3 ft (0.91 m) of length].

GWhen specified, the tolerance spreads of this table may be applied as desired. However, when not specified, the tolerances in this table will apply. It should be noted that inside diameter tolerances are based upon the outside diameter range.

8. Number of Tests

8.1 Chemical Analysis—One test per lot.

8.2 Tension—One test per lot.

8.3 Hydrostatic or Nondestructive Electric Test—Each piece in each lot.

9. Test Methods

9.1 Hydrostatic Test—Each pipe or tube with an outside diameter 1⁄8 in. (3 mm) and larger and with wall thickness of 0.015 in. (0.38 mm) and over shall be tested in accordance with Specification B 829. The allowable fiber stress for material in the condition furnished, is as follows:

UNS N06625:

Grade 1—30 000 psi (207 MPa)

Grade 2—25 000 psi (172 MPa)

UNS N06219:

All—24 000 psi (165 MPa)

UNS N06852:

All—21 000 psi (145 MPa)

9.1.1 When so agreed upon by the manufacturer and purchaser, pipe or tube may be tested to 11⁄2 times the allowable

fiber stress given above.

9.1.2 If any pipe or tube shows leak during hydrostatic testing, it shall be rejected.

9.2 Nondestructive Electric Test—Each pipe or tube shall be examined with a nondestructive electric test as per prescribed in Specification B 829.

ASTM B444 Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube ASTM B444 Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube |