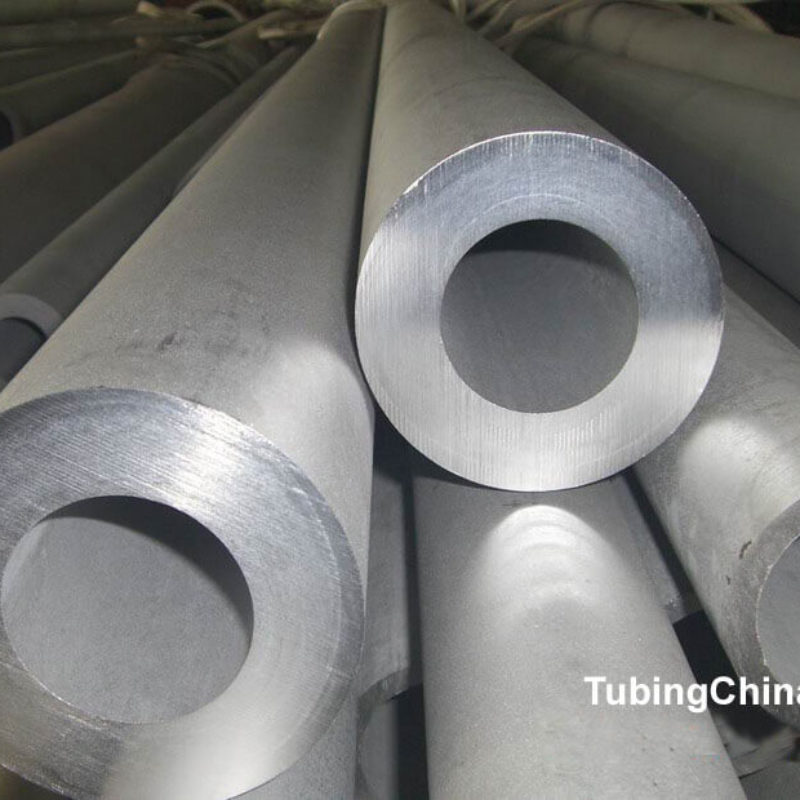

Stainless Steel Mechanical Tube

ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tubing, Stainless Steel Mechanical Tube, Stainless Steel Mechanical Pipe

Guanyu Steel Tube is a leading Manufacturer and Supplier of ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Mechanical Tubing with wide range of Grades and Sizes. ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Mechanical Tubing also known as Stainless Steel Hollow Bar, it is economical choice alternative to Stainless Steel Round Bar.

We choose the best raw material to produce ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Hollow bar, make it have good Machinability and machining properties can increase the cutting speed, reduce the tool waste.

We offer good cutting service. We can cut the Stainless Steel Mechanical Tube in any length according to the customer requirement.

ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tube main application:

Chemical Industry, Petrochemical Industry, Automotive Production Industry, Pulp and Paper Make Industries, Textile Industry, Food processing industry Sanitary Tubes, Anti-friction and Slide Bearing.

ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tube Delivery Condition:

ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Pipe Specification:

ASTM A511 / A511M Standard Specification for Seamless Stainless Steel Mechanical Tubing and Hollow Bar

EN 10294 – 1 Hollow bars for machining — Technical delivery conditions — Part 1: Non alloy and alloy steel

EN 10294 – 2 Hollow Bars for Machining – Technical delivery conditions – Part 2: Stainless Steels with Specified Machinability Properties

EN 10297 – 2 Seamless circular steel tubes for mechanical and general engineering purposes – Technical delivery conditions – Part 2: Stainless steel

| ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tube Outside Diameter: | 31.75 – 323mm; 1 1/4″ – 12″ |

| ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tube Wall Thickness: | 1.24 – 50 mm etc; |

| ASTM A511 304 304L 309S 310S 316 316L 317 321 347 Stainless Steel Mechanical Tube Standards(Norm): | EN 10216-5; EN 10294-1, EN 10294-2, EN 10297-2, DIN 17456, DIN 17458, DIN 2462, DIN 17455 |

| GB/T14975; T14976; T13296; GB5310; | |

| ASTM A213, A269, A312, A511, A789, A790, A928, A999, A1016, ASTM B161, ASTM B163, ASTM B165, ASTM B167, ASTM B338, ASTM B407, ASTM B423, ASTM B444,ASTM B619, ASTM B622, ASTM B626, ASTM B668, ASTM B677, ASTM B829 | |

| JIS G3459, JIS G3463, JIS G3446, JIS G3447, JIS G3448, JIS G3468 | |

| GOST 9940;GOST 9941 |

ASTM A511 Chemical Composition:

| Grade | Carbon | Mn | P | S | Si, max | Ni | Cr | Mo | Ti | Columbium plus Tantalum | Se |

| max | max | max | |||||||||

| MT 302 | 0.08 to 0.20 | 2 | 0.04 | 0.03 | 1 | 8.0–10.0 | 17.0–19.0 | … | … | … | … |

| MT 303 | 0.15 max | 2 | 0.2 | 0.15 min | 1 | 8.0–10.0 | 17.0–19.0 | … | … | … | … |

| MT 303Se | 0.15 max | 2 | 0.04 | 0.04 | 1 | 8.0–11.0 | 17.0–19.0 | … | … | … | 0.12–0.2 |

| MT 304 | 0.08 max | 2 | 0.04 | 0.03 | 1 | 8.0–11.0 | 18.0–20.0 | … | … | … | … |

| MT 304L | 0.035 maxA | 2 | 0.04 | 0.03 | 1 | 8.0–13.0 | 18.0–20.0 | … | … | … | … |

| MT 305 | 0.12 | 2 | 0.04 | 0.03 | 1 | 10.0–13.0 | 17.0–19.0 | … | … | … | … |

| MT 309S | 0.08 max | 2 | 0.04 | 0.03 | 1 | 12.0–15.0 | 22.0–24.0 | … | … | … | … |

| MT 310S | 0.08 max | 2 | 0.04 | 0.03 | 1 | 19.0–22.0 | 24.0–26.0 | … | … | … | … |

| MT 316 | 0.08 max | 2 | 0.04 | 0.03 | 1 | 11.0–14.0 | 16.0–18.0 | 2.0–3.0 | … | … | … |

| MT 316L | 0.035 maxA | 2 | 0.04 | 0.03 | 1 | 10.0–15.0 | 16.0–18.0 | 2.0–3.0 | … | … | … |

| MT 317 | 0.08 max | 2 | 0.04 | 0.03 | 1 | 11.0–14.0 | 18.0–20.0 | 3.0–4.0 | … | … | … |

| MT 321 | 0.08 max | 2 | 0.04 | 0.03 | 1 | 9.0–13.0 | 17.0–20.0 | … | B | … | … |

| MT 347 | 0.08 max | 2 | 0.04 | 0.03 | 1 | 9.0–13.0 | 17.0–20.0 | … | … | C | … |

A For small diameter or thin wall tubing or both, where many drawing passes are required, a maximum of 0.040 % carbon is necessary in grades MT-304L and MT-316L. Small outside diameter tubes are defined as those under a 0.500 in. [12.7 mm] outside diameter and light-wall tubes as those under a 0.049 in. [1.2 mm] average wall thickness (0.044 in. [1.1 mm] min wall thickness).

B The titanium content shall be not less than five times the carbon content and not more than 0.60 %.

C The columbium plus tantalum content shall be not less than ten times the carbon content and not more than 1.00 %.

4. Permissible Variations in Outside Diameter, Ovality, Wall Thickness, and Cut-Length Variations

(Cold-Finished Round Tubing)A

| Outside Diameter,in. | Outside Diameter, Tolerance,B in. Over and Under | Ovality,B Double Outside Diameter Tolerance when wall is: | Wall Thickness in %C,D | Wall Thickness in %C,D | Permissible Variations in Cut Length, in.E | Permissible Variations in Cut Length, in.E |

| Over | Under | Over | Under | |||

| Under 1⁄2 | 0.005 | less than 0.015 in. | 15 | 15 | 1⁄8 | 0 |

| 1⁄2 to 11⁄2 , excl | 0.005 | less than 0.065 in. | 10 | 10 | 1⁄8 | 0 |

| 11⁄2 to 31⁄2 , excl | 0.01 | less than 0.095 in. | 10 | 10 | 3⁄16 | 0 |

| 31⁄2 to 51⁄2 , excl | 0.015 | less than 0.150 in. | 10 | 10 | 3⁄16 | 0 |

| 51⁄2 to 8, exc | 0.03 | less than 0.240 in. | 10 | 10 | 3⁄16 | 0 |

| 8 to 85⁄8 , excl | 0.045 | less than 0.300 in. | 10 | 10 | 3⁄16 | 0 |

| 85⁄8 to 123⁄4 , incl | 0.062 | less than 0.350 in. | 10 | 10 | 3⁄16 | 0 |