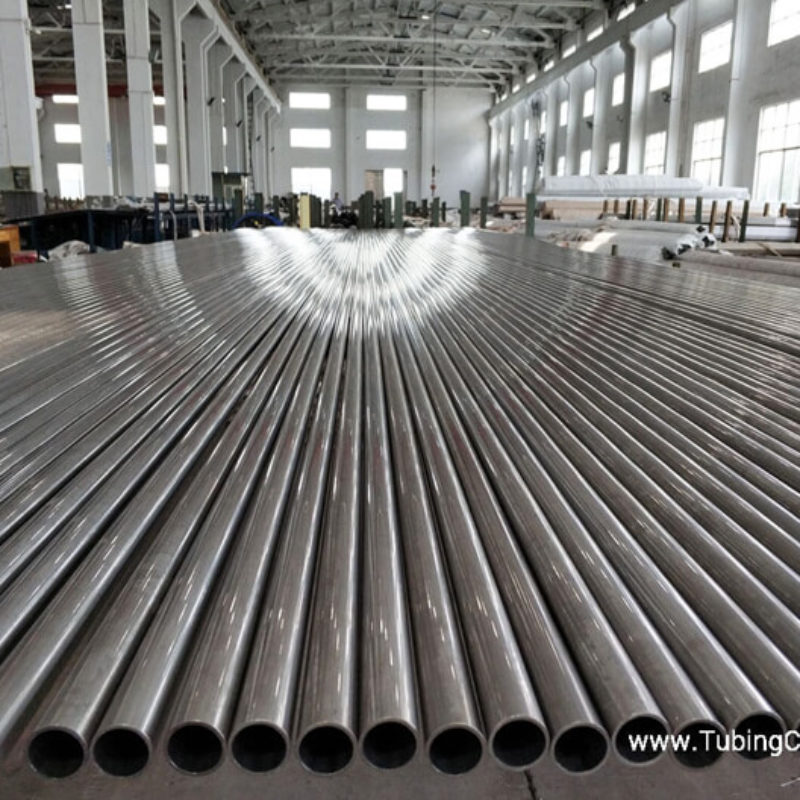

Inconel 690 Pipe Alloy 690 Pipe N06690 Alloy Tubes

Alloy 690 Product forms & sizes (mm):

Alloy 690 Bar: Φ12~Ф450

Alloy 690 Wire: Φ0.5~Ф12

Plate & Strip: δ0.2~δ350

Alloy 690 Tube: Φ4~Ф400

Other Forms & sizes: Negotiable

Alloy 690 Corrosion resistance:

Intergranular Corrosion Resistance according to ASTM A262 Practice C, under 675 ℃, 1 hour sensitizationCorrosion rate should be less than 20mdd.

Alloy 690 Pipe Inconel 690 Standard Specification

| Alloy 690 Rod, Bar, Wire and Forging stock | ASTM B / ASME SB 166,ASTM B 564 /ASME SB 564,ASME Code Case N-525,ISO 9723, MIL-DTL-24801 |

| Alloy 690 Plate, Sheet, Strip | ASTM B / ASME SB 168 /906,ASME N-525, ISO 6208,MIL-DTL-24802 |

| Inconel 690 Seamless Pipe and Alloy 690 Tube | ASTM B / ASME SB 163,ASTM B 167 / ASME SB 829,ASTM B 829 /ASME SB 829,ASME Code Cases 2083, N-20, N-525,ISO 6207, MILDTL-24803 |

Alloy 690 Pipe Inconel 690 Pipe (UNS N06690) is a high-chromium, nickel-based alloy with excellent resistance to corrosion by a variety of aqueous media and high-temperature atmospheres. It also has high strength, good metallurgical stability and excellent processing characteristics.

Alloy 690 Pipe Inconel 690 Pipe Application

The alloy’s ability to resist sulfur-containing atmospheres makes it used as a coal gasification device, a burner and furnace tube for sulfuric acid treatment, a petrochemical furnace, a heat exchanger tube, an incinerator, and a glass curing equipment for disposal of radioactive waste. The alloy shows excellent low corrosion rate and stress corrosion resistance in various types of high-temperature water, so it is widely used in steam generator heat transfer tubes, separators, tube sheets and nuclear power components.

Alloy 690 Pipe Inconel 690 Pipe Chemical Composition:

| C | Cr | Fe | Ti | Al | Nb+Ta | Cu | B |

| 0.015 ~0.03 | 27.0~31.0 | 7.0 ~11.0 | 0.5 Max | 0.5 Max | 0.1 Max | 0.2Max | 0.005 Max |

| Mn | Si | S | P | Co | N | Zr | Ni |

| 0.5Max | 0.5Max | 0.01Max | 0.015 Max | 0.05Max | 0.05 Max | 0.02 Max | 58Min |

Alloy 690 Pipe Inconel 690 Pipe Mechanical Properties

| Material | Bar &wire & Sheet, Strip and Plate | Bar &wire & Sheet, Strip and Plate | Bar &wire & Sheet, Strip and Plate | Alloy 690 Tube | Inconel 690 Tube |

| Testing temperature | At room temperature | At room temperature | At 350°C | At room temperature | At 350°C |

| Sizes (inch) | 0.5≤Φ≤3 | Φ>3 | / | / | / |

| Tensile Strength Rm (MPa) | ≥620 | ≥585 | ≥550 | ≥550 | ≥510 |

| Yield Strength Rp0.2 (MPa) | 275~345 | 240~345 | ≥190 | 240~400 | ≥190 |

| Alongation A 5D (%) | ≥25 | ≥30 | / | ≥35 | ≥30 |

Alloy 690 Pipe Inconel 690 Pipe Physical properties:

| Alloy 690 Density, kg/dm3 | 8.19 |

| Permeability | 1.001 |

| Melting range, ℃ | 1343~1377 |

| Electrical resistivity, μΩ•m | 1.148 |

| Thermal conductivity, W/m•℃ | 13.5 |

| Poisson’s ration | 0.289 |

| Coefficient of expansion (0~100°C), ×10-6/℃ | 14.06 |

| Young Modulus, GPa | 211 |

Corrosion Resistance of Nickel Alloy in difference acid

| Alloy | Sulphuric Acid | Phosphoric acid | Hydrochloric acid | Hydrofluoric acid | Nitric acid | Organic acid | Strong Alkali | Reducing salt | Oxidizing salt |

| Alloy 200 | ▲ | ▲ | ▲ | ● | ■ | ● | ● | ● | ■ |

| Monel 400 | ● | ▲ | ▲ | ● | ■ | ● | ● | ● | ■ |

| Inconel 600 | ▲ | ▲ | ■ | ▲ | ▲ | ● | ● | ● | ▲ |

| Inconel 625 | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Inconel 690 | ▲ | ● | ▲ | ● | ● | ● | ● | ● | ● |

| Incoloy 825 | ● | ● | ▲ | ■ | ● | ● | ▲ | ● | ▲ |

| Hastelloy G-3 | ● | ● | ▲ | ● | ● | ● | ● | ● | ● |

| Hastelloy C-276 | ● | ● | ▲ | ● | ▲ | ● | ● | ● | ● |

| Hastelloy B-2 | ● | ● | ● | ● | ■ | ● | ● | ● | ■ |

| ● Very Good ▲Good ■Not recommended |

Alloy 690 Pipe Inconel 690 Pipe Corrosion Rate

| Solution Component | Temperature(°C) | Corrosion rate(mm/a) |

| 10%HNO3+3%HF | 60 | 0.15 |

| 15%HNO3+3%HF | 60 | 0.25 |

| 20%HNO3+3%HF | 60 | 0.15 |