ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe

Require Quotation? Send E-mail to : sales@tubingchina.com

ASTM A213 ASME SA213 TP304 TP304L TP309S TP310S TP316 TP316L TP316Ti TP321 TP317L TP347H Stainless Steel Heat Exchanger Tubes

ASTM A312 ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe

EN 10216-5 1.4301 1.4307 1.4948 1.4401 1.4404 1.4541 1.4571 1.4438 1.4841 1.4845 1.4539 Stainless Steel Tube Tubing

ASME SA312 / SA312M Covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless-steel pipe intended for high-temperature and general corrosive service.

ASME SA312 Grades TP304, TP304L, TP304H, TP309S, TP309H, TP310S, TP310H,

TP316, TP316L, TP316H, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP348, TP348H…

Standard: ASME SA312

ASME SA312 seamless stainless tube, ASME SA312 welded seamless stainless tubes, ASTM A312 seamless stainless pipes, ASME SA312 welded seamless stainless pipes, TP304 TP304L TP304H stainless pipes, TP309S TP309H stainless pipes, TP310S TP310H stainless pipes, TP316 TP316L stainless pipes. TP321 TP321H stainless pipe, TP347 TP347H stainless pipe, seamless stainless pipe, welded stainless pipe, seamless stainless tube, welded stainless tube, Seamless Stainless-Steel Pipe.

ASME SA312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Size

OD: 17.15 - 508mm (3/8 INCH to 20 INCH)

WT: 0.5 - 60 mm, Schedule 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXH.

Production Capacity: 500 tons/Month

Require Quotation? Send E-mail to : sales@tubingchina.com

ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Application

Power generation, Boiler, Electricity, Mechanical, Shipbuilding,

Gas cylinder, Chemical, Offshore and oil service…etc.

ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Main Testing Terms and Procedure:

1. Heat Treatment and Solution Annealing / Bright Annealing

2. Cutting to required length and deburring;

3. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

4. Visual Test and Endoscope Test for Surface Quality Test

5. 100% Hydrostatic Test and 100% Eddy Current Test

6. Ultrasonic Test subject to the MPS (Material Purchase Specification)

7. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

8. Impact Test subject to Standard request

9. Grain Size Test and Intergranular Corrosion Test

10. Ultrasoic measuring of Wall Thickness

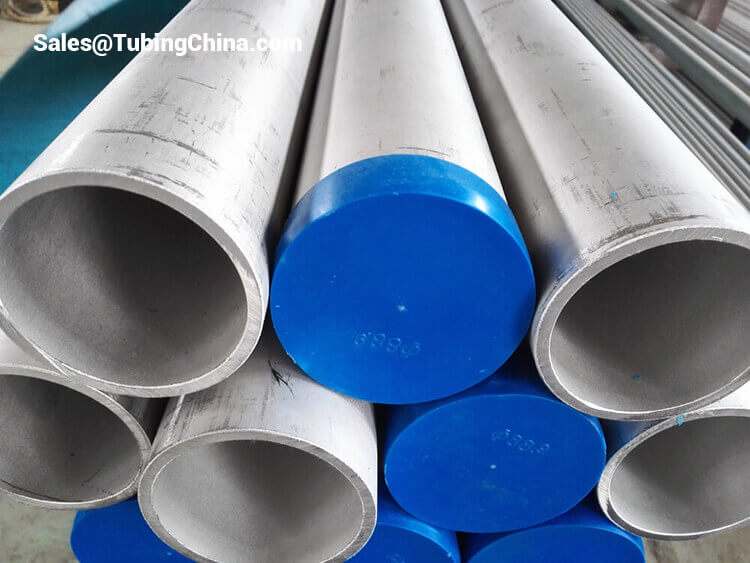

ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Marking & Packing

Marking according to MPS and Standard

Stainless Steel Tubes Ends with Caps according to PO

In Seaworthy Wooden Cases With Plastic Paper protect

In Plywood Cases With Plastic Paper Protect(Recommend, All Plywood Cases made by ourselves with lower cost.)

Steel Racks Package

Hexagonal packing in Bundles

ASTM A312 ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe Specification:

ASTM A312/A312M-17 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe ASTM A312/A312M-17 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

ASTM A790 - 16 Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe ASTM A790 - 16 Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

Nominal Pipe Size (NPS): 1/8, 1/4, 3/8, 1/2, 3/4, 1, 11/4, 11/2, 2, 21/2 inch

Outside Diameter: 10,3 - 73 mm (0,405 - 2,875 inch)

Wall Thickness: 1,73 - 7,01 (0,068 - 0,276 inch)

Notes:

Steel Grades - TP 304, TP 304L, TP 316, TP 321

- Size of pipes in accordance with ANSI/ASME B36. 19M.

- All technical requirements in accordance with ASTM A530.

- Length tolerance of measured pipes is not greater than +10 mm.

- The quality of pipes is ensured by manufacturing process and non-destructive test.

- Intergranular corrosion test in accordance with ASTM A262, Practice E is available.

ASTM A312 / A312M - 17 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe ASTM A312 / A312M - 17 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

ASME SA 312 / SA312M - 15 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe ASME SA 312 / SA312M - 15 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

Stainless Steel Pipe Specification:

Standard

Item |

ASTM A213 |

ASTM A269 |

ASTM A312 |

| Grade |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

304 304L 304H 304N 304LN

316 316L 316Ti 316N 316LN

321 321H 310S 310H 309S

317 317L 347 347H |

Yield Strength

(Mpa) |

≥170;≥205 |

≥170;≥205 |

≥170;≥205 |

Tensile Strength

(Mpa) |

≥485;≥515 |

≥485;≥515 |

≥485;≥515 |

| Elongation(%) |

≥35 |

≥35 |

≥35 |

| Hydrostatic Test |

OD(mm) Pressure max

(MPa) |

OD(mm) Pressure max

(MPa) |

OD(mm) Pressure max

(MPa) |

|

D<25.4, 7Mpa |

D<25.4, 7Mpa |

D≤88.9, 17MPa |

|

25.4≤D<38.1, 10Mpa |

25.4≤D<38.1, 10Mpa |

|

|

38.1≤D<50.8, 14Mpa |

38.1≤D<50.8, 14Mpa |

|

|

50.8≤D<76.2, 17MPa |

50.8≤D<76.2, 17MPa |

D>88.9, 19MPa |

|

76.2≤D<127, 24MPa |

76.2≤D<127, 24MPa |

|

|

D≥127, 31Mpa |

D≥127, 31Mpa |

|

|

P=220.6t/D |

P=220.6t/D |

P=2St/D S=50%Rp0.2 |

| Intergranular Corrosion Test |

ASTM A262 E |

ASTM A262 E |

ASTM A262 E |

| Eddy Current Test |

ASTM E426 |

ASTM E426 |

ASTM E426 |

O.D. Tolerance

(mm) |

O.D. and

Tolerance |

O.D. and

Tolerance |

O.D. and

Tolerance |

|

D<25.4 +/-0.10 |

D<38.1 +/-0.13 |

10.3≤D≤48.3 +0.40/-0.80 |

| |

25.4≤D≤38.1 +/-0.15 |

|

|

| |

38.1<D<50.8 +/-0.20 |

38.1≤D<88.9 +/-0.25 |

48.3<D≤114.3 +0.80/-0.80 |

|

50.8≤D<63.5 +/-0.25 |

|

|

|

63.5≤D<76.2 +/-0.30 |

88.9≤D<139.7 +/-0.38 |

114.3<D≤219.1 +1.60/-0.80 |

|

76.2≤D≤101.6 +/-0.38 |

|

|

|

101.6<D≤190.5 +0.38/-0.64 |

139.7≤D<203.2 +/-0.76 |

219.1<D≤457.0 +2.40/-0.80 |

|

190.5<D≤228.6 +0.38/-1.14 |

|

|

W.T. Tolerance

(mm) |

O.D.

W.T.

Tolerance |

O.D.

W.T.

Tolerance |

O.D.

W.T.

Tolerance |

|

D≤38.1

WT +20%/-0 |

D<12.7

WT +/-15% |

10.3≤D≤73.0

WT +20.0%/-12.5% |

|

D>38.1

WT +22%/-0 |

12.7≤D<38.1

WT +/-10% |

88.9≤D≤457.0

t/D ≤5%

WT +22.5%/-12.5% |

|

|

D≥38.1

WT: +/-10% |

88.9≤D≤457.0

t/D >5%

WT +15.0%/-12.5% |

| Sizes |

|

OD, mm |

|

Max. Length, м |

1/8 |

10,3 |

1,73; 2,11 |

12 |

1/4 |

13,7 |

2,24; 3,02 |

3/8 |

17,1 |

2,31; 3,20 |

1/2 |

21,3 |

2,11; 3,73 |

3/4 |

26,7 |

2,87; 3,91 |

1 |

33,4 |

3,38; 4,55; 6,35 |

10 |

1 1/4 |

42,4 |

3,56; 4,85; 6,35 |

1 1/2 |

48,3 |

3,68; 5,03; 7,14 |

2 |

60,3 |

3,58; 3,91; 4,37; 4,78; 6,35; 6,94; 7,14 |

2 1/2 |

73,0 |

3,58; 3,95; 4,37; 4,78; 5,16; 5,49; 6,35; 7,01 |

| Mechanical properties |

Steel Grade |

|

|

Elongation, % (min) |

TP304 |

515 |

205 |

35 |

TP304L |

485 |

170 |

35 |

TP316 |

515 |

205 |

35 |

TP316L |

485 |

170 |

35 |

TP321 |

OD < 17,1 mm - 515;

OD > 17,1 mm - 485 |

OD < 17,1 mm - 205;

OD > 17,1 mm - 170 |

35 |

| Chemical Composition (%, max) |

Steel Grade |

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

TP304 |

0,08 |

0,75 |

2 |

18 - 20 |

8 - 11 |

- |

0,03 |

0,04 |

TP304L |

0,035 |

0,75 |

2 |

18 - 20 |

8 - 13 |

- |

0,03 |

0,04 |

TP316 |

0,08 |

0,75 |

2 |

16 - 18 |

11 - 14 |

2 - 3 |

0,03 |

0,04 |

TP316L |

0,035 |

0,75 |

2 |

16 - 18 |

10 - 15 |

2 - 3 |

0,03 |

0,04 |

TP321 |

0,08 |

0,75 |

2 |

17 - 20 |

9 - 13 |

- |

0,03 |

0,04 |

ASTM A213 ASME SA213 TP304 TP304L TP309S TP310S TP316 TP316L TP316Ti TP321 TP317L TP347H Stainless Steel Heat Exchanger Tubes

ASME SA 312 TP304 TP304L TP304H TP316 TP316L TP317L TP321 TP316Ti TP347 TP347H TP310S TP309S Stainless Steel Pipe

EN 10216-5 1.4301 1.4307 1.4948 1.4401 1.4404 1.4541 1.4571 1.4438 1.4841 1.4845 1.4539 Stainless Steel Tube Tubing

ASTM A213 ASME SA213 304H 321H 347H 309S 310S 316H S31035 800HT N08811 N08825 Reheater Tubes and Superheater Tubes for Boiler

ASTM A269 TP304 TP304L TP316 TP316L TP321 Seamless and Welded Austenitic Stainless Steel Tubing

ASTM A789 ASME SA 789 S31803 S32205 S32101 S32750 S32760 S32304 S31500 S31260 Seamless Tubes

ASTM A790 ASME SA790 S31803 S32205 S32101 S32750 S32760 S32304 S31500 S31260 Seamless Pipe

EN 10216-5 1.4462 1.4362 1.4162 1.4410 1.4501 Seamless Tubes

Difference Between ASTM A213 and ASTM A269

Difference Between ASTM A213 and ASTM A312

Nominal Pipe Size ⅛ to Nominal Pipe Size 3½

| Nominal Pipe Size |

DN

mm |

OD

inches (mm) |

Wall Thickness

inches (mm) |

| SCH 5 |

SCH 10 |

SCH 30 |

SCH 40/STD |

SCH 80 |

SCH 120 |

SCH 160 |

XXS |

| ⅛ |

6 |

0.405 in (10.29 mm) |

0.035 in (0.889 mm) |

0.049 in (1.245 mm) |

0.057 in (1.448 mm) |

0.068 in (1.727 mm) |

0.095 in (2.413 mm) |

--- |

--- |

--- |

| ¼ |

8 |

0.540 in (13.72 mm) |

0.049 in (1.245 mm) |

0.065 in (1.651 mm) |

0.073 in (1.854 mm) |

0.088 in (2.235 mm) |

0.119 in (3.023 mm) |

--- |

--- |

--- |

| ⅜ |

10 |

0.675 in (17.15 mm) |

0.049 in (1.245 mm) |

0.065 in (1.651 mm) |

0.073 in (1.854 mm) |

0.091 in (2.311 mm) |

0.126 in (3.200 mm) |

--- |

--- |

--- |

| ½ |

15 |

0.840 in (21.34 mm) |

0.065 in (1.651 mm) |

0.083 in (2.108 mm) |

--- |

0.109 in (2.769 mm) |

0.147 in (3.734 mm) |

--- |

4.78mm |

0.294 in (7.47 mm) |

| ¾ |

20 |

1.050 in (26.67 mm) |

0.065 in (1.651 mm) |

0.083 in (2.108 mm) |

2.41mm |

0.113 in (2.870 mm) |

0.154 in (3.912 mm) |

--- |

5.56mm |

0.308 in (7.823 mm) |

| 1 |

25 |

1.315 in (33.40 mm) |

0.065 in (1.651 mm) |

0.109 in (2.769 mm) |

2.90mm |

0.133 in (3.378 mm) |

0.179 in (4.547 mm) |

--- |

6.35mm |

0.358 in (9.093 mm) |

| 1¼ |

32 |

1.660 in (42.16 mm) |

0.065 in (1.651 mm) |

0.109 in (2.769 mm) |

0.117 in (2.972 mm) |

0.140 in (3.556 mm) |

0.191 in (4.851 mm) |

--- |

6.35mm |

0.382 in (9.703 mm) |

| 1½ |

40 |

1.900 in (48.26 mm) |

0.065 in (1.651 mm) |

0.109 in (2.769 mm) |

0.125 in (3.175 mm) |

0.145 in (3.683 mm) |

0.200 in (5.080 mm) |

--- |

7.14mm |

0.400 in (10.160 mm) |

| 2 |

50 |

2.375 in (60.33 mm) |

0.065 in (1.651 mm) |

0.109 in (2.769 mm) |

0.125 in (3.175 mm) |

0.154 in (3.912 mm) |

0.218 in (5.537 mm) |

0.250 in (6.350 mm) |

8.74mm |

0.436 in (11.074 mm) |

| 2½ |

65 |

2.875 in (73.02 mm) |

0.083 in (2.108 mm) |

0.120 in (3.048 mm) |

0.188 in (4.775 mm) |

0.203 in (5.156 mm) |

0.276 in (7.010 mm) |

0.300 in (7.620 mm) |

0.344 in (8.738 mm) |

0.552 in (14.021 mm) |

| 3 |

80 |

3.500 in (88.90 mm) |

0.083 in (2.108 mm) |

0.120 in (3.048 mm) |

0.188 in (4.775 mm) |

0.216 in (5.486 mm) |

0.300 in (7.620 mm) |

0.350 in (8.890 mm) |

0.438 in (11.13 mm) |

0.600 in (15.240 mm) |

| 3½ |

90 |

4.000 in (101.60 mm) |

0.083 in (2.108 mm) |

0.120 in (3.048 mm) |

0.188 in (4.775 mm) |

0.226 in (5.740 mm) |

0.318 in (8.077 mm) |

--- |

--- |

0.636 in (16.154 mm) |

Nominal Pipe Size 4 to Nominal Pipe Size 9

| NPS |

DN

mm |

OD

inches (mm) |

Wall thickness

inches (mm) |

| SCH 5 |

SCH 10 |

SCH 20 |

SCH 30 |

SCH 40/STD |

SCH 60 |

SCH 80 |

SCH 100 |

SCH 120 |

SCH 140 |

SCH 160 |

| 4 |

100 |

4.500 in (114.30 mm) |

0.083 in (2.108 mm) |

0.120

in

(3.

048 mm) |

--- |

0.188

in

(4.

775 mm) |

0.237 in (6.02 mm) |

0.281

in (7.137 mm) |

0.337 in (8.560 mm) |

--- |

0.437

in (11.13 mm) |

--- |

0.531

in (13.49 mm) |

| 4½ |

115 |

5.000 in (127.00 mm) |

--- |

--- |

--- |

--- |

0.247 in (6.274 mm) |

--- |

0.355 in (9.017 mm) |

--- |

--- |

--- |

--- |

| 5 |

125 |

5.563 in (141.30 mm) |

0.109 in (2.769 mm) |

0.134

in

(3.404 mm) |

--- |

--- |

0.258 in (6.553 mm) |

--- |

0.375 in (9.525 mm) |

--- |

0.500

in (12.70 mm) |

--- |

0.625

in (15.875 mm) |

| 6 |

150 |

6.625 in (168.27 mm) |

0.109 in (2.769 mm) |

0.134

in (3.404 mm) |

--- |

--- |

0.280 in (7.112 mm) |

--- |

0.432 in (10.973 mm) |

--- |

0.562

in (14.27 mm) |

--- |

0.719

in (18.263 mm) |

| 8 |

200 |

8.625 in (219.08 mm) |

0.109 in (2.769 mm) |

0.148

in (3.759 mm) |

0.250

in

(6.

35 mm) |

0.277

in

(7.

036 mm) |

0.322 in (8.179 mm) |

0.406

in

(10.

312 mm) |

0.500 in (12.70 mm) |

0.593

in

(15.

09 mm) |

0.718

in (18.2 6mm) |

0.812

in

(20.

62mm) |

0.906

in (23.01 mm) |

Nominal Pipe Size 10 to Nominal Pipe Size 24

| Nominal Pipe Size |

DN

mm |

OD

inches (mm) |

Wall Thickness

inches (mm) |

| SCH 5s |

SCH 5 |

SCH 10s |

SCH 10 |

SCH 20 |

SCH 30 |

| 10 |

250 |

10.75 in (273.05 mm) |

0.134 in (3.404 mm) |

0.134 in (3.404 mm) |

0.165 in (4.191 mm) |

0.165 in (4.191 mm) |

0.250 in (6.350 mm) |

0.307 in (7.798 mm) |

| 12 |

300 |

12.75 in (323.85 mm) |

0.156 in (3.962 mm) |

0.165 in (4.191 mm) |

0.180 in (4.572 mm) |

0.180 in (4.572 mm) |

0.250 in (6.350 mm) |

0.330 in (8.382 mm) |

| 14 |

350 |

14.00 in (355.60 mm) |

0.156 in (3.962 mm) |

0.156 in (3.962 mm) |

0.188 in (4.775 mm) |

0.250 in (6.350 mm) |

0.312 in (7.925 mm) |

0.375 in (9.525 mm) |

| 16 |

400 |

16.00 in (406.40 mm) |

0.165 in (4.191 mm) |

0.165 in (4.191 mm) |

0.188 in (4.775 mm) |

0.250 in (6.350 mm) |

0.312 in (7.925 mm) |

0.375 in (9.525 mm) |

| 18 |

450 |

18.00 in (457.20 mm) |

0.165 in (4.191 mm) |

0.165 in (4.191 mm) |

0.188 in (4.775 mm) |

0.250 in (6.350 mm) |

0.312 in (7.925 mm) |

0.437 in (11.100 mm) |

| 20 |

500 |

20.00 in (508.00 mm) |

0.188 in (4.775 mm) |

0.188 in (4.775 mm) |

0.218 in (5.537 mm) |

0.250 in (6.350 mm) |

0.375 in (9.525 mm) |

0.500 in (12.700 mm) |

| 24 |

600 |

24.00 in (609.60 mm) |

0.218 in (5.537 mm) |

0.218 in (5.537 mm) |

0.250 in (6.350 mm) |

0.250 in (6.350 mm) |

0.375 in (9.525 mm) |

0.562 in (14.275 mm) |

| Nominal Pipe Size |

Wall thickness

inches (mm) |

| SCH 40s |

SCH 40 |

SCH 60 |

SCH 80s |

SCH 80 |

SCH 100 |

SCH 120 |

SCH 140 |

SCH 160 |

| 10 |

0.365 in (9.271 mm) |

0.365 in (9.271 mm) |

0.500 in (12.700 mm) |

0.500 in (12.700 mm) |

0.593 in (15.062 mm) |

0.718 in (18.237 mm) |

0.843 in (21.412 mm) |

1.000 in (25.400 mm) |

1.125 in (28.575 mm) |

| 12 |

0.375 in (9.525 mm) |

0.406 in (10.312 mm) |

0.500 in (12.700 mm) |

0.500 in (12.700 mm) |

0.687 in (17.450 mm) |

0.843 in (21.412 mm) |

1.000 in (25.400 mm) |

1.125 in (28.575 mm) |

1.312 in (33.325 mm) |

| 14 |

0.375 in (9.525 mm) |

0.437 in (11.100 mm) |

0.593 in (15.062 mm) |

0.500 in (12.700 mm) |

0.750 in (19.050 mm) |

0.937 in (23.800 mm) |

1.093 in (27.762 mm) |

1.250 in (31.750 mm) |

1.406 in (35.712 mm) |

| 16 |

0.375 in (9.525 mm) |

0.500 in (12.700 mm) |

0.656 in (16.662 mm) |

0.500 in (12.700 mm) |

0.843 in (21.412 mm) |

1.031 in (26.187 mm) |

1.218 in (30.937 mm) |

1.437 in (36.500 mm) |

1.593 in (40.462 mm) |

| 18 |

0.375 in (9.525 mm) |

0.562 in (14.275 mm) |

0.750 in (19.050 mm) |

0.500 in (12.700 mm) |

0.937 in (23.800 mm) |

1.156 in (29.362 mm) |

1.375 in (34.925 mm) |

1.562 in (39.675 mm) |

1.781 in (45.237 mm) |

| 20 |

0.375 in (9.525 mm) |

0.593 in (15.062 mm) |

0.812 in (20.625 mm) |

0.500 in (12.700 mm) |

1.031 in (26.187 mm) |

1.280 in (32.512 mm) |

1.500 in (38.100 mm) |

1.750 in (44.450 mm) |

1.968 in (49.987 mm) |

| 24 |

0.375 in (9.525 mm) |

0.687 in (17.450 mm) |

0.968 in (24.587 mm) |

0.500 in (12.700 mm) |

1.218 in (30.937 mm) |

1.531 in (38.887 mm) |

1.812 in (46.025 mm) |

2.062 in (52.375 mm) |

2.343 in (59.512 mm) |

|