Tolerances to EN 10051 Continuously Rolled Hot Rolled Plate

This standard covers continuously rolled hot rolled flat products with a rolled width of 600 - 2200mm inclusive in non-alloy, alloy and stainless steel. Strip of width < 600mm slit from wide strip is therefore covered by the standard.

EN 10048 covers hot rolled flat products with a rolled width of < 600mm.

Thickness is < 25 mm.

As the standard covers a wide range of steel, the tolerances depend on the type of steel. Stainless steel falls into one of 3 categories:

Ferritic and martensitic category B

Non-Mo alloyed austenitic category C

Mo-alloyed austenitic category D

These classes are driven by the hot workability at rolling temperature. There are notable omissions from this list, duplex and precipitation hardening steel. It can be guessed that duplex stainless steel should be in category D whilst precipitation hardening steel should be in category B.

Tolerances for sheets and plates cut from coil

Thickness

The table below gives the basic tolerances for a category A steel. The standard then states that these basic tolerances are increased by a % based on the category:

Category B - 15%

Category C - 30%

Category D - 40%

Of course, this approach gives rise to rounding errors. There is no guidance in the standard as to how to treat this.

Thickness tolerances for category A steel

| Nominal thickness |

Tolerances for nominal width |

| < 1200 |

> 1200 < 1500 |

> 1500 < 1800 |

> 1800 |

| < 2.00 |

± 0.17 |

± 0.19 |

± 0.21 |

-- |

| > 2.00 < 2.50 |

± 0.18 |

± 0.21 |

± 0.23 |

± 0.25 |

| > 2.50 < 3.00 |

± 0.20 |

± 0.22 |

± 0.24 |

± 0.26 |

| > 3.00 < 4.00 |

± 0.22 |

± 0.24 |

± 0.26 |

± 0.27 |

| > 4.00 < 5.00 |

± 0.24 |

± 0.26 |

± 0.28 |

± 0.29 |

| > 5.00 < 6.00 |

± 0.26 |

± 0.28 |

± 0.29 |

± 0.31 |

| > 6.00 < 8.00 |

± 0.29 |

± 0.30 |

± 0.31 |

± 0.35 |

| > 8.00 < 10.00 |

± 0.32 |

± 0.33 |

± 0.34 |

± 0.40 |

| > 10.00 < 12.50 |

± 0.35 |

± 0.36 |

± 0.37 |

± 0.43 |

| > 12.50 < 15.00 |

± 0.37 |

± 0.38 |

± 0.40 |

± 0.46 |

| > 15.00 < 25.00 |

± 0.40 |

± 0.42 |

± 0.45 |

± 0.50 |

The thickness shall be measured at any point at least 40mm from the edges for products with mill edges and at least 25mm from the edges for products with trimmed edges.

Length tolerance

This does not depend on the steel category.

| Nominal length (L) |

Tolerances |

| Lower |

Upper |

| < 2000 |

0 |

+ 10 |

| > 2000 < 8000 |

0 |

+ 0.005 x L |

| > 8000 |

0 |

+ 40 |

The length shall be measured along one of the longer edges of the sheet/plate.

Width tolerance

This does not depend on the steel category. Note that the standard says that the width depends on nominal length. This does not seem logical and it may be inferred that this is an error.

| Nominal length |

Tolerances |

| Mill edges |

Trimmed edges1) |

| Lower |

Upper |

Lower |

Upper |

| < 1200 |

0 |

+ 20 |

0 |

+ 3 |

| > 1200 < 1500 |

0 |

+ 20 |

0 |

+ 5 |

| > 1500 |

0 |

+ 20 |

0 |

+6 |

- Tolerances for trimmed edges apply to products with nominal thicknesses < 10mm. For nominal thicknesses > 10mm the upper tolerances shall be agreed at the time of the enquiry and order.

The width shall be measured at right angles to the longitudinal axis of the product.

Flatness

This is dependent on the steel category.

| Nominal width |

Tolerances on flatness for category |

| B |

C |

D |

| < 1200 |

18 |

23 |

Shall be agreed at the time of the enquiry and order |

| > 1200 < 1500 |

23 |

30 |

| > 1500 |

28 |

38 |

Closer tolerances for categories B and C may be agreed at the time of enquiry and order

The flatness shall be determined by measuring the deviation in distance between the product and a flat horizontal surface on which it is placed.

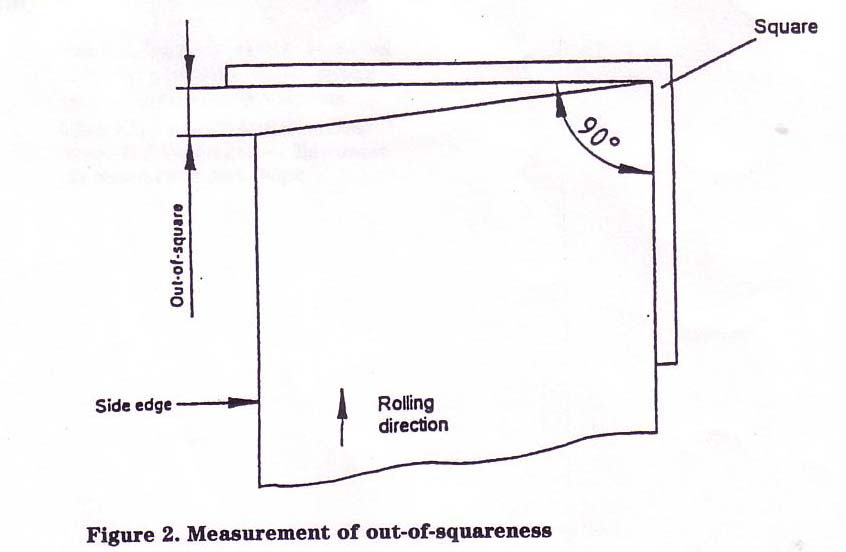

Out of squareness

This shall not exceed 1% of the actual width of the plate as defined by the diagram below:

Edge camber

The edge camber shall not exceed 0.5% of the actual length of the for a nominal length of < 5000mm.

For sheet/plate with a nominal length > 5000mm and widths > 600mm, the edge camber shall not exceed 20mm for any length of 5000mm for sheet/plate with mill edges and 15mm for sheet/plate with trimmed edges.

Superposition of dimensions

By agreement at the time of enquiry and order the tolerances on out of squareness and edge camber may be replaced by a requirement that a perfect rectangle of the ordered dimensions can be superimposed on the delivered sheets/plates.

Tolerances for products in coil form

All the above tolerances apply to individual sheets. In addition, there are requirements for products in coil form.

General

The specified values for tolerances shall not apply to the uncropped ends of the coil for a total length L which is calculated using the formula:

L (in metres) = 90/Nominal thickness (in mm) provided that the result does not exceed 20 metres.

Thickness

The same as for sheet/plate.

Width

The same as for sheet/plate.

Crown

There are tolerances for crown for Category A steel used for cold rolling. However, there is no definition for Category B, C or D steels. There is not even the usual reference "must be agreed at time of enquiry and order". However, the lack of a positive reference to crown for stainless steels can only imply that such an agreement is necessary.

Related References:

|