Residual Stress

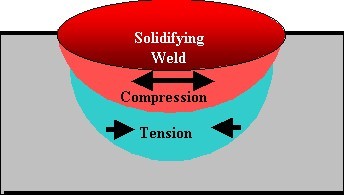

If a run of weld is applied to a plate, the heated area below is expands,but the bulk of the material stops it. Therefore the area below the welds is in compression, caused by tension from bulk of the material stopping it from expanding.

If a run of weld is applied to a plate, the heated area below is expands,but the bulk of the material stops it. Therefore the area below the welds is in compression, caused by tension from bulk of the material stopping it from expanding.

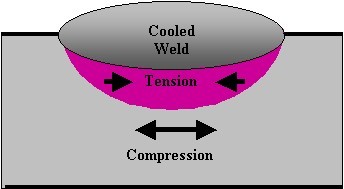

When the weld cools, it contracts, but the bulk of the material stops it. This leaves the weld and the area immediately below it, in Compression.

When the weld cools, it contracts, but the bulk of the material stops it. This leaves the weld and the area immediately below it, in Compression.

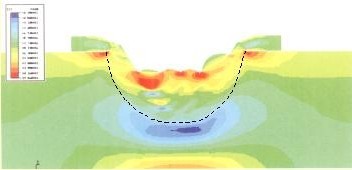

Below is the finite element simulation of a weld repair. The program can be used to find a suitable welding sequence that will minimise residual stress, and thus avoid having to perform costly post weld stress relif after welding. Note the blue compressive region underneath the weld repair.

Related References:

Related References:

Stress Definition

|

|