Chemical Composition for API5L PSL 2 Pipes

Chemical composition for PSL 2 pipe with t ≤ 25,0 mm (0.984 in)

| Steel grade (steel name) |

Mass fraction, based upon heat and product analyses

% maximum |

Carbon equivalenta

% maximum |

| C b |

Si |

Mn b |

P |

S |

V |

Nb |

Ti |

Other |

CEiiw |

CEpcm |

| Seamless and welded pipes |

| L245R or BR |

0,24 |

0,40 |

1,20 |

0,025 |

0,015 |

c |

c |

0,04 |

e |

0,43 |

0,25 |

| L290R or X42R |

0,24 |

0,40 |

1,20 |

0,025 |

0,015 |

0,06 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L245N or BN |

0,24 |

0,40 |

1,20 |

0,025 |

0,015 |

c |

c |

0,04 |

e |

0,43 |

0,25 |

| L290N or X42N |

0,24 |

0,40 |

1,20 |

0,025 |

0,015 |

0,06 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L320N or X46N |

0,24 |

0,40 |

1,40 |

0,025 |

0,015 |

0,07 |

0,05 |

0,04 |

d,e |

0,43 |

0,25 |

| L360N or X52N |

0,24 |

0,45 |

1,40 |

0,025 |

0,015 |

0,10 |

0,05 |

0,04 |

d,e |

0,43 |

0,25 |

| L390N or X56N |

0,24 |

0,45 |

1,40 |

0,025 |

0,015 |

0,10f |

0,05 |

0,04 |

d,e |

0,43 |

0,25 |

| L415N or X60N |

0,24f |

0,45f |

1,40f |

0,025 |

0,015 |

0,10f |

0,05 |

0,04f |

g,h |

as agreed |

| L245Q or BQ |

0,18 |

0,45 |

1,40 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L290Q or X42Q |

0,18 |

0,45 |

1,40 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L320Q or X46Q |

0,18 |

0,45 |

1,40 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L360Q or X52Q |

0,18 |

0,45 |

1,50 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L390Q or X56Q |

0,18 |

0,45 |

1,50 |

0,025 |

0,015 |

0,07 |

0,05 |

0,04 |

d,e |

0,43 |

0,25 |

| L415Q or X60Q |

0,18f |

0,45f |

1,70f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L450Q or X65Q |

0,18f |

0,45f |

1,70f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L485Q or X70Q |

0,18f |

0,45f |

1,80f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L555Q or X80Q |

0,18f |

0,45f |

1,90f |

0,025 |

0,015 |

g |

g |

g |

i,j |

as agreed |

| Welded pipe |

| L245M or BM |

0,22 |

0,45 |

1,20 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L290M or X42M |

0,22 |

0,45 |

1,30 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L320M or X46M |

0,22 |

0,45 |

1,30 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e |

0,43 |

0,25 |

| L360M or X52M |

0,22 |

0,45 |

1,40 |

0,025 |

0,015 |

d |

d |

d |

e |

0,43 |

0,25 |

| L390M or X56M |

0,22 |

0,45 |

1,40 |

0,025 |

0,015 |

d |

d |

d |

e |

0,43 |

0,25 |

| L415M or X60M |

0,12f |

0,45f |

1,60f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L450M or X65M |

0,12f |

0,45f |

1,60f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L485M or X70M |

0,12f |

0,45f |

1,70f |

0,025 |

0,015 |

g |

g |

g |

h |

0,43 |

0,25 |

| L555M or X80M |

0,12f |

0,45f |

1,85f |

0,025 |

0,015 |

g |

g |

g |

i |

0,43f |

0,25 |

| L625M or X90M |

0,10 |

0,55f |

2,10f |

0,020 |

0,010 |

g |

g |

g |

i |

--- |

0,25 |

| L690M or X100M |

0,10 |

0,55f |

2,10f |

0,020 |

0,010 |

g |

g |

g |

i,j |

0,25 |

| L830M or X120M |

0,10 |

0,55f |

2,10f |

0,020 |

0,010 |

g |

g |

g |

i,j |

0,25 |

Table ---Chemical composition for PSL 2 pipe with t ≤ 25,0 mm (0.984 in) (Continued)

a Based upon product analysis. For seamless pipe with t > 20,0 mm (0.787 in), the carbon equivalent limits shall be as agreed. The CEiiw limits apply if the carbon mass fraction is greater than 0,12 % and the CEpcm limits apply if the carbon mass fraction is less than or equal to 0,12 %.

b For each reduction of 0,01 % below the specified maximum for carbon, an increase of 0,05 % above the specified maximum for manganese is permissible, up to a maximum of 1,65 % for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but < L485 or X70; up to a maximum of 2,00 % for grades ≥L485 or X70, but ≤ L555 or X80; and up to a maximum of 2,20 % for grades >L555 or X80.

c Unless otherwise agreed , the sum of the niobium and vanadium concentrations shall be ≤ 0,06 %.

d The sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

e Unless otherwise agreed, 0,50 % maximum for copper, 0,30 % maximum for nickel, 0,30 % maximum for chromium and 0,15 % maximum for molybdenum.

f Unless otherwise agreed.

g Unless otherwise agreed, the sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

h Unless otherwise agreed, 0,50 % maximum for copper, 0,50 % maximum for Nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

i Unless otherwise agreed, 0,50 % maximum for copper, 1,00 % maximum for nickel, 0,50 % maximum for chromium and 0,50 % maximum for molybdenum.

j 0,004 % maximum for boron.

Chemical compostion

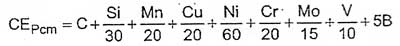

9.2.4 For PSL 2 pipe with a product analysis carbon mass fraction equal to or less than 0,12 %, the carbon equivalent, CEpcm, shall be determined using Equation (2):

where the symbols for the chemical elements represent the mass fraction in percent (see Table 5).

.If the heat analysis for boron is less than 0,000 5 % then it is not necessary for the product analysis to include boron, and the boron content may be considered to be zero for the CEpcm calculation.

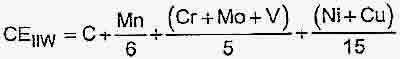

9.2.5 For PSL 2 pipe with a product analysis carbon mass fraction greater than 0,12 % the carbon equivalent, CEllw shall be determined using Equation (3):

where the symbols for the chemical elements represent the mass fraction in percent (see Table 5).

NOTE: A derogation from the ISO rules for the presentation of chemical equations has been granted for Equations (2) and (3) in deference to their longstanding use in the industry.

Related References:

API 5CT. Tubing

API 5L. Line Pipes

OCTG API 5L ASTM Line Pipes Specification

Chemical Composition for API 5L PSL 1 Pipes

Chemical Composition for API 5L PSL 2 Pipes

API 5L PSL 1 Pipe Mechanical Properties Tensile Strength

API 5L PSL 2 Pipe Mechanical Properties Tensile Strength

API 5L PSL 2 Pipes Impact Test Table

API 5L Steel Number Steel Designation Equivalent Table ISO 3138 EN 10027-2 |