Relation of Hardness to Mechanical Properties Tensile Strength

Hardness covers several properties: resistance to deformation, resistance to friction and abrasion.

The well known correlation links hardness with tensile strength, while resistance to deformation is dependent on modulus of elasticity. The frictional resistance may be divided in two equally important parts: the chemical affinity of materials in contact, and the hardness itself.

So it is easy to understand that surface treatments modify frictional coefficients and behaviour of the parts in contact. The abrasion resistance is partially related to hardness (between 2 metallic parts in frictional contact, the less hard one will be the more rapidly worn), but experiments carried out at Centre de Recherches PECHINEY in Voreppe (CRV), with TABER test show that the correlation resistance against wear/ hardness presents some inversions.

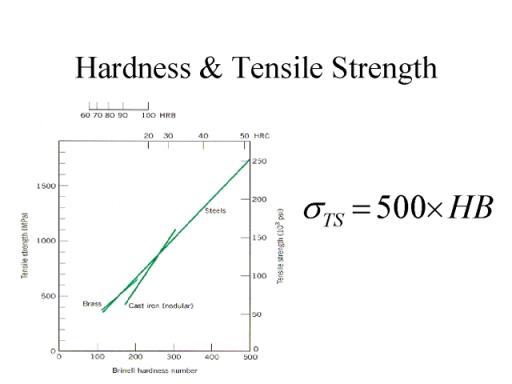

A correlation may be established between hardness and some other material property such as tensile strength. Then the other properties (such as strength) may be estimated based on hardness test results, which are much simpler to obtain. This correlation depends upon specific test data and cannot be extrapolated to include other materials not tested.

The yield strength in tension is about 1/3 of the hardness. To find the ball park figure for the yield strength convert the hardness number to MPa (or psi ) and divide by 3. For example take the Vickers number, which has the dimension kg/mm2, and multiply by 10 to (approximately) convert it to /mm2 (=MPa) then divide by three.

For example: HV 300 corresponds to a Sigma-y of approximately 1000 MPa. An approximate relationship between the hardness and the tensile strength (of steel) is,

Where HB is the Brinnell Hardness of the material, as measured with a standard indenter and a 3000 kgf load.

Figure 23. Harfdness & Tensile Strength

Wear is generally affected by several factors, among them materials selection, friction, surface load, sliding distance, surface hardness, surface finish, and lubrication. Controlling these factors can contribute to a successful application by helping to prevent wear and premature product failure. Wear can be defined as both material loss and deformation at contact surfaces. Wear results in particle generation and surface degradation

Properties are high wear resistance; high strength , hardness and fracture toughness; low porosity; high creep and corrosion resistance; The hardness of a metal limits the ease with which it can be machined, since toughness decreases as hardness increases Toughness is a combination of high strength and medium ductility. It is the ability of a material or metal to resist fracture, plus the ability to resist failure after the damage has begun. A tough metal, such as cold chisel, is one that can withstand considerable stress, slowly or suddenly applied, and which will deform before failure. Toughness is the ability of a material to resist the start of permanent distortion plus the ability to resist shock or absorb energy

|