Tolerances to ISO 9444 ontinuously Rolled Hot Rolled Strip

This standard covers continuously rolled hot rolled flat products of rolled widths > 600 mm in stainless steels. It therefore is designed to replace EN 10051. The maximum width is increased to 2500 mm compared to EN 10051.

Tolerances are defined for thickness is < 13mm. Special agreement is required for > 13mm.

The tolerances are the same for all grades of stainless steel. This is in contrast to previous standards and previous drafts of this standard.

This simple categorisation removes the apparent omission from EN 10051 of duplex and precipitation hardening steels. It also removes the difference between ferritic and martensitic grades and non-Mo austenitics.

Thickness

Thickness tolerances for hot rolled wide strip

| Specified thickness (t) |

Tolerances on specified thickness for nominal width (w) |

| w < 1400 |

1400 < w < 2500 |

| t < 2.0 |

± 0.22 |

± 0.27 |

| 2.0 < t < 2.5 |

± 0.23 |

± 0.30 |

| 2.5 < t < 3.0 |

± 0.26 |

± 0.31 |

| 3.0 < t < 4.0 |

± 0.29 |

± 0.34 |

| 4.0 < t < 5.0 |

± 0.31 |

± 0.36 |

| 5.0 < t < 6.0 |

± 0.34 |

± 0.38 |

| 6.0 < t < 8.0 |

± 0.38 |

± 0.40 |

| 8.0 < t <10.0 |

± 0.42 |

± 0.44 |

| 10.0 < t <13.0 |

± 0.46 |

± 0.48 |

| t >13.0 |

The tolerances have to be agreed at the time of enquiry and order |

These tolerances include crown. If an agreement on crown is agreed separately, the measurement of crwon shall be from the centre-line to a point at least 40mm from the edges for products with mill edges and at least 25mm from the edges for products with trimmed edges.

The thickness shall be measured at any point at least 40mm from the edges for products with mill edges and at least 25mm from the edges for products with trimmed edges.

The tolerances shall not apply to the uncropped ends of the coil for a total length L in metres which is calculated using the formula:

L = 90/t (in mm) provided that the result does not exceed 20 metres per coil.

Trimmed or sheared edges may have burrs.

For widths up to 30mm, the thickness is measured at any point on the longitudinal axis.

For widths above 30mm it is measured at any point at least 10mm or 15mm from the longitudinal edges for slit or mill edges respectively.

Thickness variations for strip intended for cold rolling

EN 10051 was somewhat ambiguous in this area. This standard is quite specific.

Permitted thickness difference within one coil for cold rolling wide strip

| Specified thickness (t) |

Permitted thickness differences for width of strip w |

| w < 1200 |

1200 < w < 1500 |

1500 < w < 2500 |

| t < 2.0 |

0.20 |

0.24 |

0.28 |

| 2.0 < t < 3.0 |

0.22 |

0.27 |

0.33 |

| 3.0 < t < 13.0 |

0.28 |

0.32 |

0.40 |

The thickness (within one coil) shall change gradually and shall not occur with visible discontinuity.

Length tolerance

These apply to both wide and narrow products cut from coils

| Specified length (L) |

Tolerances |

| Lower |

Upper |

| L < 2000 |

0 |

+ 10 |

| 2000 < L < 20000 |

0 |

+ 0.005 x L |

| L > 20000 |

To be agreed |

The length shall be measured along one of the longer edges of the sheet/plate.

Width tolerance

For wide strip and sheet/plate cut from wide strip with thickness < 10mm, the tolerance on width is +20/-0 for mill edges and +5/-0 for slit edges. For thickness > 10mm, the width tolerance shall be agreed at the time of enquiry and order.

Flatness

For plate/sheet cut from wide strip of thickness < 13mm, the flatness tolerance shall be as in table below.

Tolerances on flatness for sheet/plate

| Specified width (w) |

Tolerances on flatness |

| 600 < w < 1200 |

23 |

| 1200 < w < 1500 |

30 |

| w > 1500 |

38 |

The flatness shall be determined by measuring the deviation in distance between the product and a flat horizontal surface on which it is placed.

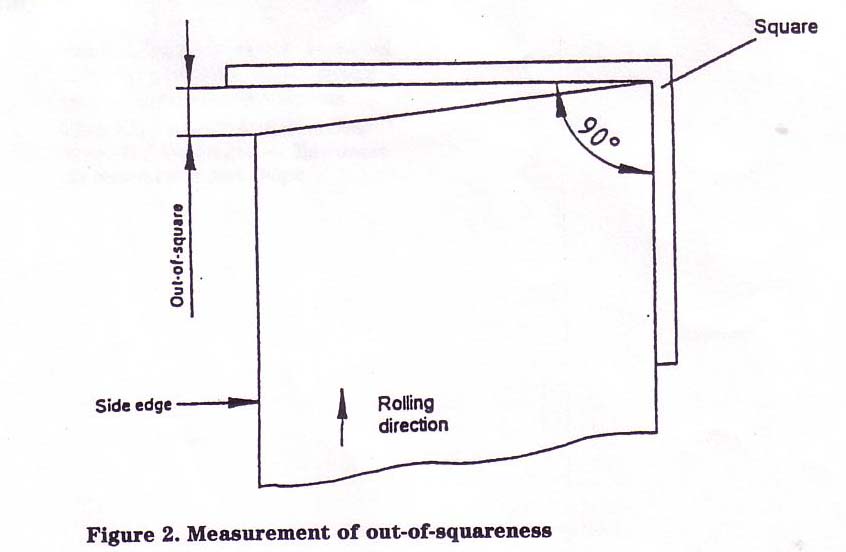

Out of squareness

This shall not exceed 1% of the actual width of the plate as defined by the diagram below:

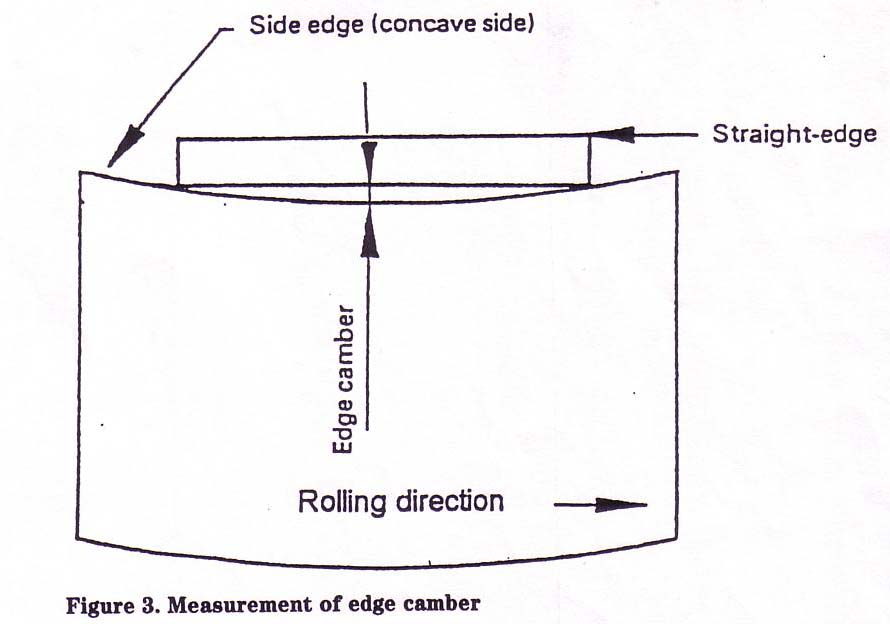

Edge camber

For hot rolled wide strip, the edge camber shall not exceed 20mm of any length of 5000 mm in the case of strip with mill edges and 15 mm in the case of strip with trimmed edges.

For sheet/plate cut from wide strip edge camber shall not exceed 0.5% of the specified length for a specified length of < 5000mm.

For sheet/plate cut from wide strip with a specified length > 5000mm, the edge camber shall not exceed 20mm for any length of 5000mm for sheet/plate with mill edges and 15mm for sheet/plate with slit edges.

Edge camber is measured as in the diagram below:

Edge camber is not normally measured unless compliance is in doubt.

Superposition of dimensions

By agreement at the time of enquiry and order the tolerances on out of squareness and edge camber may be replaced by a requirement that a perfect rectangle of the ordered dimensions can be superimposed on the delivered sheets/plates or cut lengths.

Related References:

ISO Tolerance Table

ISO Tolerances For Fasteners

Tolerances to ISO 9445 Cold Rolled Narrow and Wide Strip

Tolerances to ISO 9444 ontinuously Rolled Hot Rolled Strip

ISO Steel Pipe Tube and Fittings Standard and Specifications

Tolerances to ISO 18286 hot rolled stainless steel quarto plate

|