Tolerances to ISO 9445 Cold Rolled Narrow and Wide Strip

ISO 9445 is designed to bring together tolerances for cold rolled narrow and wide stainless steel strip. It has officially superseded EN 10258 and EN 10259 although of course customers and suppliers are entitled to continue to use these standards. In most respects the tolerances from these standards are identical to the ones in this new ISO standard. The major differences are:

- Additional table for wide strip is included which is based on Japanese practice.

- Slightly different edge camber tolerances than in EN 10259 for wide strip.

- Provision for width tolerance on wide strip with mill edges.

Narrow stainless steel strip is defined as having a rolled width of < 600mm and thickness < 3mm. This is the same definition as in EN 10258. This covers material slit from such products and cut lengths.

Wide stainless steel strip is defined as having a rolled width of 600 - 2100 mm from 0.3-8.0mm thick. It therefore includes material slit from this product with actual width < 600mm and sheet/plate

The phrase "specified thickness" is preferred to "nominal thickness" in this ISO standard.

There is a view that the combination of all cold rolled products into one standard can be confusing. There are moves towards separating out narrow and wide products into two standards. This summary adopts this approach as for every tolerance type there are different values for narrow and wide products.

Narrow strip

Thickness tolerance

Tolerances on specified thickness for narrow cold rolled strip

| Specified Thickness (t) |

| w < 125 |

125 < w < 250 |

250 < w < 600 |

| Normal |

Fine

(F) |

Precision

(P) |

Normal |

Fine (F) |

Precision

(P) |

Normal |

Fine (F) |

Precision

(P) |

| 0.05 < t < 0.10 |

±0.10t |

±0.06t |

±0.04t |

±0.12t |

±0.10t |

±0.08t |

±0.15t |

±0.10t |

±0.08t |

| 0.10 < t < 0.15 |

± 0.010 |

±0.008 |

±0.006 |

±0.015 |

±0.012 |

±0.008 |

±0.020 |

±0.015 |

±0.010 |

| 0.15 < t < 0.20 |

±0.015 |

±0.010 |

±0.008 |

±0.020 |

±0.012 |

±0.010 |

±0.025 |

±0.015 |

±0.012 |

| 0.20 < t < 0.25 |

±0.015 |

±0.012 |

±0.008 |

±0.020 |

±0.015 |

±0.010 |

±0.025 |

±0.020 |

±0.012 |

| 0.25 < t < 0.30 |

±0.017 |

±0.012 |

±0.009 |

±0.025 |

±0.015 |

±0.012 |

±0.030 |

±0.020 |

±0.015 |

| 0.30 < t < 0.40 |

±0.020 |

±0.015 |

±0.010 |

±0.025 |

±0.020 |

±0.012 |

±0.030 |

±0.025 |

±0.015 |

| 0.40 < t < 0.50 |

±0.025 |

±0.020 |

±0.012 |

±0.030 |

±0.020 |

±0.015 |

±0.035 |

±0.025 |

±0.018 |

| 0.50 < t < 0.60 |

±0.030 |

±0.020 |

±0.014 |

±0.030 |

±0.025 |

±0.015 |

±0.040 |

±0.030 |

±0.020 |

| 0.60 < t < 0.80 |

±0.030 |

±0.025 |

±0.015 |

±0.035 |

±0.030 |

±0.018 |

±0.040 |

±0.035 |

±0.025 |

| 0.80 < t < 1.00 |

±0.030 |

±0.025 |

±0.018 |

±0.040 |

±0.030 |

±0.020 |

±0.050 |

±0.035 |

±0.025 |

| 1.00 < t < 1.20 |

±0.035 |

±0.030 |

±0.020 |

±0.045 |

±0.035 |

±0.025 |

±0.050 |

±0.040 |

±0.030 |

| 1.20 < t < 1.50 |

±0.040 |

±0.030 |

±0.020 |

±0.050 |

±0.035 |

±0.025 |

±0.060 |

±0.045 |

±0.030 |

| 1.50 < t < 2.00 |

±0.050 |

±0.035 |

±0.025 |

±0.060 |

±0.040 |

±0.030 |

±0.070 |

±0.050 |

±0.035 |

| 2.00 < t < 2.50 |

±0.050 |

±0.035 |

±0.025 |

±0.070 |

±0.045 |

±0.030 |

±0.080 |

±0.060 |

±0.040 |

| 2.50 < t < 3.00 |

±0.060 |

±0.045 |

±0.030 |

±0.070 |

±0.050 |

±0.035 |

±0.090 |

±0.070 |

±0.045 |

- This table is identical to the table in EN 10258.

- By agreement the tolerances may alternatively be totally + or totally - or unevenly distributed. In any case the total tolerance shall be as in the table.

- For thicknesses below 0.05mm the values for the tolerances are to be agreed at the time of the enquiry and order.

Width tolerance

Tolerances on width for narrow cold rolled strip and cut lengths

|

Specified

Thickness (t) |

Specified Width (w) |

| w < 40 |

40 < w < 125 |

125 < w < 250 |

250 < w < 600 |

| Normal |

Fine F |

Precision (P) |

Normal |

Fine (F) |

P |

Normal |

Fine (F) |

P |

Normal |

Fine (F) |

P |

| t < 0.25 |

+0.17

/-0 |

+0.17

/-0 |

+0.10

/-0 |

+0.20

/-0 |

+0.15

/-0 |

+0.12

/-0 |

+0.25

/-0 |

+0.20

/-0 |

+0.15

/-0 |

+0.50

/-0 |

+0.50

/-0 |

+0.40

/-0 |

| 0.25 < t < 0.50 |

+0.20

/-0 |

+0.15

/-0 |

+0.12

/-0 |

+0.25

/-0 |

+0.20

/-0 |

+0.15

/-0 |

+0.30

/-0 |

+0.22

/-0 |

+0.17

/-0 |

+0.60

/-0 |

+0.50

/0 |

+0.40

/-0 |

| 0.50 < t < 1.00 |

+0.25

/-0 |

+0.20

/-0 |

+0.15

/-0 |

+0.25

/-0 |

+0.22

/-0 |

+0.17

/-0 |

+0.40

/-0 |

+0.25

/-0 |

+0.20

/-0 |

+0.70

/-0 |

+0.60

/-0 |

+0.50

/-0 |

| 1.00 < t < 1.50 |

+0.25

/-0 |

+0.22

/-0 |

+0.15

/-0 |

+0.30

/-0 |

+0.25

/-0 |

+0.17

/-0 |

+0.50

/-0 |

+0.30

/-0 |

+0.22

/-0 |

+1.0

/-0 |

+0.70

/-0 |

+0.60

/-0 |

| 1.50 < t < 2.50 |

--- |

--- |

--- |

+0.40

/-0 |

+0.25

/-0 |

+0.20

/-0 |

+0.60

/-0 |

+0.40

/-0 |

+0.25

/-0 |

+1.0

/-0 |

+0.80

/-0 |

+0.60

/-0 |

| 2.50 < t < 3.00 |

--- |

--- |

--- |

+0.50

/-0 |

+0.3

/-0 |

+0.25

/-0 |

+0.6

/-0 |

+0.40

/-0 |

+0.25

/-0 |

+1.2

/-0 |

+1.0

/-0 |

+0.80

/-0 |

- This table is identical to the one in EN 10258.

- By agreement, the tolerances may be equally ± or all negative. In both cases, the total range of the tolerances shall be as in the table.

Length tolerance

Length tolerances for cut lengths from narrow strip

| Specified length L |

Tolerances |

| Normal |

Special |

| L < 2000 |

+3/-0 |

+1.5/-0 |

| 2000 < L < 4000 |

+5/-0 |

+2/-0 |

- This is identical to the table in EN 10258

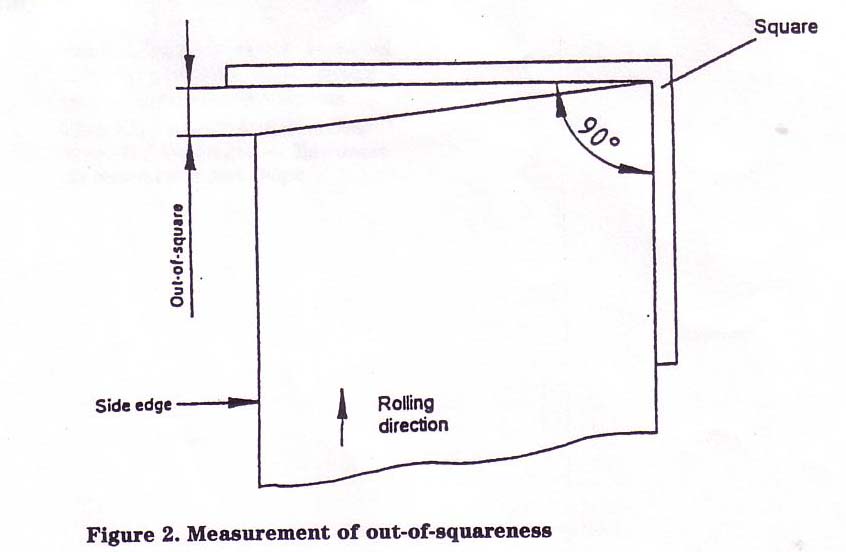

Edge camber

Tolerances on edge camber for cold rolled narrow strip and cut lengths

| Specified width w |

Edge camber tolerances for measuring lengths |

| 1000 |

2000 |

1000 |

2000 |

| Normal |

Precision |

| 10 < w < 25 |

4 |

16 |

1.5 |

6 |

| 25 < w < 40 |

3 |

12 |

1.25 |

5 |

| 40 < w < 125 |

2 |

8 |

1.0 |

4 |

| 125 < w < 600 |

1.5 |

6 |

0.75 |

3 |

- This table is identical to the one in EN 10258.

- If applicable, both measuring lengths shall be used.

- These tolerances do not apply to the work hardened condition. Any requirement for this material shall be agreed at the time of enquiry and order.

Out of squareness

The out of squareness tolerance for cut lengths from narrow strip > 250mm shall not exceed 0.5% of the actual width of the product.

For widths < 250mm the tolerances shall be agreed at the time of enquiry and order.

These requirements are identical to those in EN 10258.

Flatness

The flatness tolerance for cut lengths from narrow strip shall not exceed 10mm for normal cases and 7mm where a special tolerance is required.

This does not apply to material in the work hardened condition which must be agreed at the time of the enquiry and order.

These requirements are identical to those in EN 10258.

Edge Waviness

For skin passed or stretch levelled narrow strip, the ratio of the wave height to wave length shall be a maximum of 0.03 for specified thicknesses < 1.00mm and a maximum of 0.02 for > 1.00mm.

These requirements are identical to those in EN 10258.

-------------------------------------------------------------------------------------------------------------------------------------------------

Wide strip

Thickness tolerance

The standard allows for two methods for defining thicknesses tolerance:

Method A - identical to EN 10259. Thickness is measured at any point located more than 20mm from the edge for slit edges and 30mm for mill edges.

Method B - Thickness is measured at any point located more than 15mm from the edge for slit edges and 25mm for mill edges. This is similar to Japanese standards.

Tolerances on specified thickness for cold rolled wide strip Method A

| Specified thickness (t) |

Normal tolerances for a nominal width w of |

Special tolerances (S) for a nominal width w of |

| w<1000 |

1000<w<1300 |

1300<w<2100 |

w<1000 |

1000<w<1300 |

1300<w<2100 |

| t < 0.30 |

±0.030 |

-- |

-- |

±0.020 |

-- |

-- |

| 0.30 < t < 0.50 |

±0.04 |

±0.04 |

-- |

±0.025 |

±0.030 |

-- |

| 0.50 < t < 0.60 |

±0.045 |

±0.05 |

-- |

±0.030 |

±0.035 |

-- |

| 0.60 < t < 0.80 |

±0.05 |

±0.05 |

-- |

±0.035 |

±0.040 |

-- |

| 0.80 < t < 1.00 |

±0.055 |

±0.06 |

±0.06 |

±0.040 |

±0.045 |

±0.050 |

| 1.00 < t < 1.20 |

±0.06 |

±0.07 |

±0.07 |

±0.045 |

±0.045 |

±0.050 |

| 1.20 < t < 1.50 |

±0.07 |

±0.08 |

±0.08 |

±0.050 |

±0.055 |

±0.060 |

| 1.50 < t < 2.00 |

±0.08 |

±0.09 |

±0.10 |

±0.055 |

±0.060 |

±0.070 |

| 2.00 < t < 2.50 |

±0.09 |

±0.10 |

±0.11 |

-- |

-- |

-- |

| 2.50 < t < 3.00 |

±0.11 |

±0.12 |

±0.12 |

-- |

-- |

-- |

| 3.00 < t < 4.00 |

±0.13 |

±0.14 |

±0.14 |

-- |

-- |

-- |

| 4.00 < t < 5.00 |

±0.14 |

±0.15 |

±0.15 |

-- |

-- |

-- |

| 5.00 < t < 6.50 |

±0.15 |

±0.15 |

±0.16 |

-- |

-- |

-- |

| 6.50 < t < 8.00 |

±0.16 |

±0.17 |

±0.17 |

|

|

|

- This table is similar to that in EN 10259 except that there is an extra line for 6.50 < t < 8.00.

- Also there are some differences in the number of decimal places for Special tolerances.

- Thickness is measured at any point located more than 20mm from the edge for slit edges and 30mm for mill edges - defined as Method A.

- For strip and cut lengths < 30mm wide the thickness shall be measured at the centre of the strip.

Tolerances on specified thickness for cold rolled wide strip Method B

| Specified thickness (t) |

Normal tolerances for a nominal width w of |

Special tolerances (S) for a nominal width w of |

| w<1000 |

1000<w<1300 |

1300<w<2100 |

w<1000 |

1000<w<1300 |

1300<w<2100 |

| t < 0.30 |

±0.030 |

-- |

-- |

±0.030 |

-- |

-- |

| 0.30 < t < 0.50 |

±0.04 |

±0.04 |

-- |

±0.030 |

±0.035 |

-- |

| 0.50 < t < 0.60 |

±0.045 |

±0.05 |

-- |

±0.035 |

±0.035 |

-- |

| 0.60 < t < 0.80 |

±0.05 |

±0.05 |

-- |

±0.040 |

±0.040 |

-- |

| 0.80 < t < 1.00 |

±0.055 |

±0.06 |

±0.07 |

±0.040 |

±0.050 |

±0.050 |

| 1.00 < t < 1.20 |

±0.06 |

±0.07 |

±0.08 |

±0.050 |

±0.055 |

±0.060 |

| 1.20 < t < 1.50 |

±0.08 |

±0.08 |

±0.10 |

±0.055 |

±0.060 |

±0.060 |

| 1.50 < t < 2.00 |

±0.08 |

±0.09 |

±0.11 |

±0.065 |

±0.070 |

±0.080 |

| 2.00 < t < 2.50 |

±0.09 |

±0.11 |

±0.13 |

-- |

-- |

-- |

| 2.50 < t < 3.00 |

±0.11 |

±0.13 |

±0.15 |

-- |

-- |

-- |

| 3.00 < t < 4.00 |

±0.14 |

±0.15 |

±0.16 |

-- |

-- |

-- |

| 4.00 < t < 5.00 |

±0.15 |

±0.17 |

±0.19 |

-- |

-- |

-- |

| 5.00 < t < 6.00 |

±0.17 |

±0.20 |

±0.23 |

-- |

-- |

-- |

| 6.00 < t < 8.00 |

±0.17 |

±0.22 |

±0.25 |

|

|

|

- Thickness is measured at any point located more than 15mm from the edge for slit edges and 25mm for mill edges - defined as Method B.

-

For strip and cut lengths < 30mm wide the thickness shall be measured at the centre of the strip.

- Note the difference in the last two thickness bands compared to Method A.

Width tolerance

Provision is made in this standard for width tolerances for mill edges.

For wide strip and sheet/plate cut from wide strip with mill edges < 1000mm, the tolerance is +25/-0mm.

For wider material the tolerance is +30/-0mm.

For wide strip with slit edges the tolerances are as in the table below:

Tolerances on wide cold rolled strip and sheet/plate cut from wide strip

| Specified thickness (t) |

Normal tolerances for a specfied width w of |

Special tolerances (S)1) for a nominal width w of |

| w<125 |

125<w<250 |

250<w<600 |

600<w<1000 |

1000<w<2100 |

w<125 |

125<w<250 |

250<w<600 |

| t < 1.00 |

+0.5/-0 |

+0.5/-0 |

+0.7/-0 |

+1.5/-0 |

+2.0/-0 |

+0.3/-0 |

+0.3/-0 |

+0.6/-0 |

| 1.00 < t < 1.50 |

+0.7/-0 |

+0.7/-0 |

+1.0/-0 |

+1.5/-0 |

+2.0/-0 |

+0.4/-0 |

+0.5/-0 |

+0.7/-0 |

| 1.50 < t < 2.50 |

+1.0/-0 |

+1.0/-0 |

+1.2/-0 |

+2.0/-0 |

+2.5/-0 |

+0.6/-0 |

+0.7/-0 |

+0.9/-0 |

| 2.50 < t < 3.50 |

+1.2/-0 |

+1.2/-0 |

+1.5/-0 |

+3.0/-0 |

+3.0/-0 |

+0.8/-0 |

+0.9/-0 |

+1.0/-0 |

| 3.50 < t < 8.00 |

+2.0/-0 |

+2.0/-0 |

+1.2/-0 |

+4.0/-0 |

+4.0/-0 |

-- |

-- |

-- |

- By special agreement, products can be supplied with permissible undersizes on the nominal width. In this case, the values in this table apply as the oversize plus undersize range. E.g. 1.20 mm thick, 700 mm wide could be ordered to +1.0/-0.5mm by agreement.

- For material with edges re-cut by shearing, the tolerances on width may by agreement be increased to 5mm

- This table is similar to that in EN 10259 except that the highest nominal thickness is now 8.00mm.

Length tolerance

Length tolerances also have both 'normal' and 'special' tolerance ranges. 'Special' tolerance should be specifically requested. Each range is proportional to the length of the sheet or cut length, with a minimum tolerance at 2000mm length. Unlike the old standards, these tolerances apply for any length that can be supplied, and across the whole thickness range.

| Nominal Length L |

Tolerances |

| Normal |

Special (S) |

| L < 2000 |

+5/-0 |

+3/-0 |

| 2000 < L |

+0.0025 x L/-0 |

+0.0015 x L/-0 |

- This is identical to that in EN 10259

Edge camber

Tolerances on edge camber for wide strip and plate/sheet from wide strip

| Specified width (w) |

Edge camber tolerances for measuring lengths |

| 1000 |

2000 |

| 10 < w < 40 |

2.5 |

10 |

| 40 < w < 125 |

2 |

8 |

| 125 < w < 600 |

1.5 |

6 |

| 600 < w < 2100 |

1 |

4 |

- If applicable both measuring lengths shall be used.

- This table is the same as that in EN 10259 for widths from 40mm upwards. Two width bands in EN 10259 have been combined in this standard into the 10-40mm band and new values specified.

Out of Squareness

As in EN 10259 there are two ways to specify out of squareness and the values are identical to this standard.

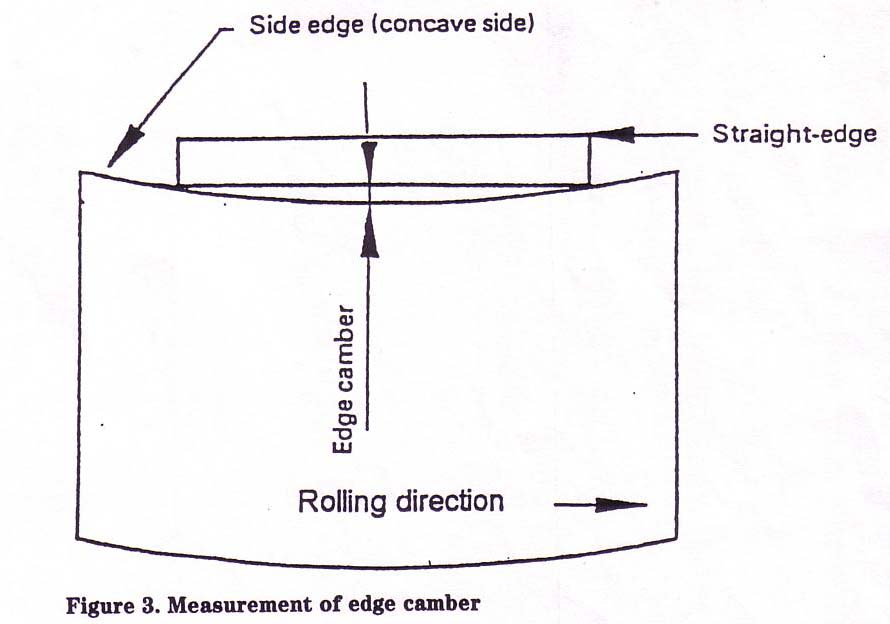

Out of squareness is defined in Fig 2 below:

OR

Option 2 - shall not exceed the values in the table:

All dimensions in mm

| Length L of sheet plate or cut length |

Maximum difference in diagonal lengths |

| L < 3000 |

6 |

| 3000 < L < 6000 |

10 |

| > 6000 |

15 |

Ordered format

When ordering an agreement may be made that the ordered format (i.e. width and length) be contained in every piece supplied. In this case, the tolerances on width, length, edge camber and out of squareness shall be agreed at the time of the enquiry and order.Flatness tolerance

The flatness tolerance of of stainless steel strip, sheet/plate and cut length shall not exceed 10mm for normal cases and 7mm where a special tolerance (FS) is required for length < 3000mm and 12mm for normal cases and 8mm where a special tolerance (FS) is required for length > 3000mm. This is identical to the requirements of EN 10259.These requirements do not apply to work hardened material or condition 2D.

Related References:

ISO Tolerance Table

ISO Tolerances For Fasteners

Tolerances to ISO 9445 Cold Rolled Narrow and Wide Strip

Tolerances to ISO 9444 ontinuously Rolled Hot Rolled Strip

ISO Steel Pipe Tube and Fittings Standard and Specifications

Tolerances to ISO 18286 hot rolled stainless steel quarto plate

|