Tolerances to EN 10259 Cold Rolled Wide Stainless Steel Strip

Thickness tolerance

Preferred thicknesses are shown and are intended to indicate which gauges are more likely to be available on an ex-stock basis from suppliers. Buyers of other thicknesses may be required to purchase full coil weight quantities.

Compared with the old British Standard tolerances, EN 10259 has the following differences:

- Tolerances are given up to 6.5mm thick, rather than finishing below 3.0mm.

- There is a 'normal' tolerance and also a 'special' tolerance at some thicknesses and widths. The 'special' range is about 70% of the normal range, and also symmetrical about the nominal. The old British Standards have only one range.

- In EN 10259, the range varies a little across 3 groups of ordered widths, whereas the old BS tolerances did not vary with the width.

- The new 'normal' ranges are close to the old British Standard ranges.

- Purchasers who wish to order 'special' thickness tolerances should enquire about their availability with the supplier. There may be some restrictions associated with these tolerances.

The following is taken from the standard. It is not totally clear from the standard but the nominal widths defined in the table are the original rolled width not the slit width of the coil. All dimensions in mm.

| Nominal thickness |

Normal tolerances for a nominal width w of |

Special tolerances (S) for a nominal width w of |

| Equal to and over |

less than |

w<1000 |

1000<w<1300 |

1300<w<2100 |

w<1000 |

1000<w<1300 |

1300<w<2100 |

| ---------- |

0.30 |

±0.03 |

-- |

-- |

±0.02 |

-- |

-- |

| 0.30 |

0.50 |

±0.04 |

±0.04 |

-- |

±0.025 |

±0.030 |

-- |

| 0.50 |

0.60 |

±0.045 |

±0.05 |

-- |

±0.030 |

±0.035 |

-- |

| 0.60 |

0.80 |

±0.05 |

±0.05 |

-- |

±0.035 |

±0.040 |

-- |

| 0.80 |

1.00 |

±0.055 |

±0.06 |

±0.06 |

±0.040 |

±0.045 |

±0.050 |

| 1.00 |

1.20 |

±0.06 |

±0.07 |

±0.07 |

±0.045 |

±0.045 |

±0.050 |

| 1.20 |

1.50 |

±0.07 |

±0.08 |

±0.08 |

±0.050 |

±0.055 |

±0.06 |

| 1.50 |

2.00 |

±0.08 |

±0.09 |

±0.10 |

±0.055 |

±0.06 |

±0.07 |

| 2.00 |

2.50 |

±0.09 |

±0.10 |

±0.11 |

-- |

-- |

-- |

| 2.50 |

3.00 |

±0.11 |

±0.12 |

±0.12 |

-- |

-- |

-- |

| 3.00 |

4.00 |

±0.13 |

±0.14 |

±0.14 |

-- |

-- |

-- |

| 4.00 |

5.00 |

±0.14 |

±0.15 |

±0.15 |

-- |

-- |

-- |

| 5.00 |

6.501) |

±0.15 |

±0.15 |

±0.16 |

-- |

-- |

-- |

1) Includes 6.50

Width tolerance

Width tolerances are all positive, unlike the standards replaced that had equal plus and minus tolerances EN 10259 has both 'normal' and 'special' ranges, the special tolerances being closest to those in the standard replaced, so if the 'old' width tolerances are required, then the EN 10259 special tolerances should be specified.

| Nominal thickness |

Normal tolerances 1) for a nominal width w of |

Special tolerances (S)1) for a nominal width w of |

| Equal to and over |

less than |

w<1252) |

125<w<2502) |

250<w<6002) |

600<w<10002) |

1000<w<21002) |

w<125 |

125<w<250 |

250<w<600 |

| -- |

1.00 |

+0.5/-0 |

+0.5/-0 |

+0.7/-0 |

+1.5/-0 |

+2.0/-0 |

+0.3/-0 |

+0.3/-0 |

+0.6/-0 |

| 1.00 |

1.50 |

+0.7/-0 |

+0.7/-0 |

+1.0/-0 |

+1.5/-0 |

+2.0/-0 |

+0.4/-0 |

+0.5/-0 |

+0.7/-0 |

| 1.50 |

2.50 |

+1.0/-0 |

+1.0/-0 |

+1.2/-0 |

+2.0/-0 |

+2.5/-0 |

+0.6/-0 |

+0.7/-0 |

+0.9/-0 |

| 2.50 |

3.50 |

+1.2/-0 |

+1.2/-0 |

+1.5/-0 |

+3.0/-0 |

+3.0/-0 |

+0.8/-0 |

+0.9/-0 |

+1.0/-0 |

| 3.50 |

6.503) |

+2.0/-0 |

+2.0/-0 |

+1.2/-0 |

+4.0/-0 |

+4.0/-0 |

-- |

-- |

-- |

- By special agreement, products can be supplied with permissible undersizes on the nominal width. In this case, the values in this table apply as the oversize plus undersize range. E.g. 1.20 mm thick, 700 mm wide could be ordered to +1.0/-0.5mm by agreement.

- For material with edges re-cut by shearing, the tolerances on width may by agreement be increased to 5mm

- Including 6.50 mm

Length tolerance

Length tolerances also have both 'normal' and 'special' tolerance ranges. 'Special' tolerance should be specifically requested. Each range is proportional to the length of the sheet or cut length, with a minimum tolerance at 2000mm length. Unlike the old standard, these tolerances apply for any length that can be supplied, and across the whole thickness range.

| Nominal Length L |

Tolerances |

| Normal |

Special (S) |

| L < 2000 |

+5/-0 |

+3/-0 |

| 2000 < L |

+0.0025 x L/-0 |

+0.0015 x L/-0 |

Flatness and edge waviness tolerances

In contrast to the standards replaced, EN 10259 introduces tolerances for flatness of sheet, plate and cut lengths, with both a 'normal' and 'special' range. There is a larger tolerance range above 3000mm lengths. This greater tolerance also applies to strip, for which there is also a limitation of edge waviness.

The flatness tolerance of of strip, sheet/plate and cut length shall not exceed 10mm for normal cases and 7mm where a special tolerance (FS) is required for length < 3000mm and 12mm for normal cases and 8mm where a special tolerance (FS) is required for length > 3000mm.

For strip, the waviness of the edges, i.e. the ratio of wave height (h) to wave length (l) shall be max 0.03 for all thicknesses.

These requirements do not apply to work hardened material for which any requirement must be agreed between manufacturer and customer.

Out-of-squareness and edge camber

EN 10259 and the old British Standard take different approaches. The old standards specified that the nominal rectangular ordered dimensions (the 'ordered format') must be capable of being inscribed within the actual pieces supplied. EN 10259 allows this as an option, which may be specifically requested. If so requested, then the tolerances on width, length, out-of-square and edge camber can be re-negotiated. However, as the principal method of control, the EN defines the limit of out-of-squareness in two alternative ways, either through the difference in diagonal lengths, or by a direct measurement of the deviation from rectangular shape.

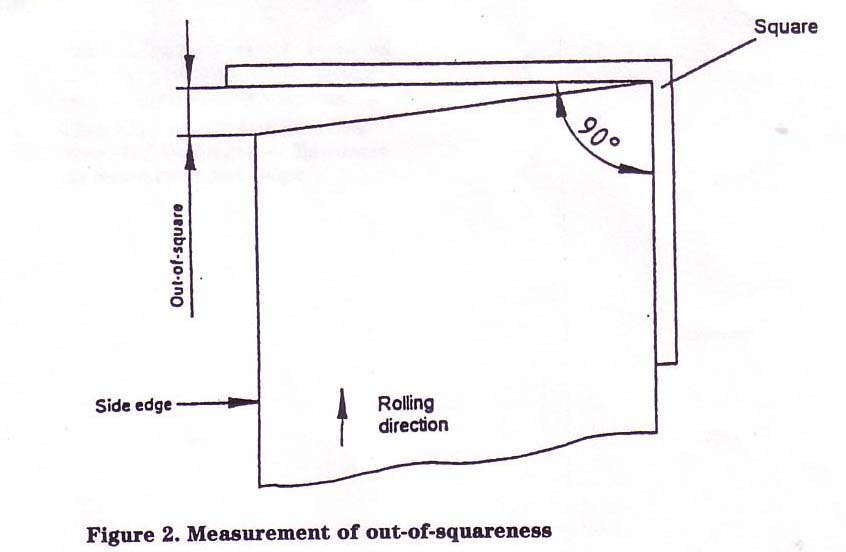

Option 1 - The out-of-squareness of sheets/plates and cut lengths shall not exceed 0.5% of the width of the product. Out of squareness is defined in Fig 2 below:

OR

Option 2 - shall not exceed the values in the table:

All dimensions in mm

| Length L of sheet plate or cut length |

Maximum difference in diagonal lengths |

| L < 3000 |

6 |

| 3000 < L < 6000 |

10 |

| > 6000 |

15 |

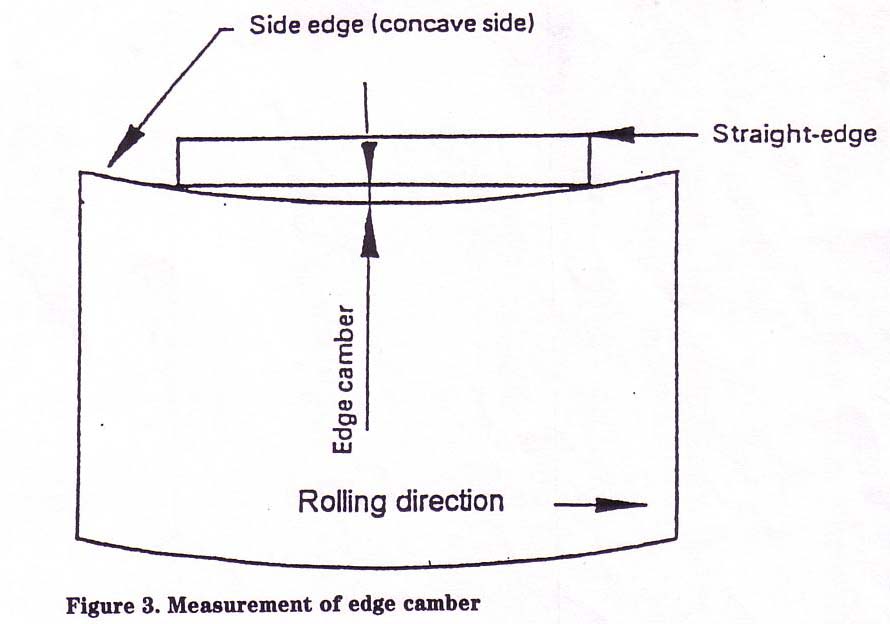

In a similar way, the EN defines limiting edge camber of sheets, plates and cut lengths, measured over either a 1000mm or 2000mm length. The old standards did not specify edge camber limits. Edge camber is defined as shown in Fig 3:

| Specified Width |

Edge camber tolerances for measuring length |

| equal to and over |

less than |

1000 |

2000 |

| 10 |

25 |

4 |

16 |

| 25 |

40 |

3 |

12 |

| 40 |

125 |

2 |

8 |

| 125 |

500 |

1.5 |

6 |

| 500 |

2100 |

1 |

4 |

Advantages of using EN 10259

EN 10259 has the following benefits over the requirements in the withdrawn BS 1501-3 and BS 1449-2:

- It quite clearly applies to all product forms cut from cold rolled wide strip i.e. strip rolled to a width of 600mm or more. It therefore covers wide strip, sheet, plate, slit strip and cut lengths of whatever final width or length.

- It clearly does not apply to cold rolled narrow strip or products cut from narrow strip, with a rolling width of less than 600mm, for which EN 10258 exists. This narrow strip is also called precision strip.

- It recognises that cold rolled products are now available up to 6.5mm thick and 2100mm wide.

- Although the European and British definition of the boundary between 'plate' and 'sheet' is at 3mm, the tables cover the whole range, and don't depend on this distinction.

- It includes systematic requirements for flatness, out-of-squareness and edge camber.

- It describes the measurement method(s) for each parameter.

- For most parameters, there is a 'normal' requirement, plus alternative 'special' requirement.

- Widespread adoption of this standard throughout Europe will enable producers to manufacture in a more consistent way, giving greater flexibility to supply across Europe, leading to shorter lead times with lower stocks, but faster, more flexible response.

- Dimensional standardisation will help satisfy customers throughout Europe.

- The standard offers a concise method of defining purchase requirements, so reducing the risk of doubt or confusion.

Related References:

Cold Rolling

Cold Rolled Steel Thickness Weight Table

Cold rolled stainless steel Tube

Tolerances to EN 10259 Cold Rolled Wide Stainless Steel Strip

Tolerances to EN 10258 Cold Rolled Narrow stainless steel strip

|