Preventing Corrosion in Cooling System

Water and water/glycol solutions are common heat transfer fluids used in cooling systems and recirculating chillers. Although the fluids are the lifeblood for your heat transfer applications, they can also cause corrosion within your systems. This corrosion can result in a reduction in system thermal performance due to scaling on the heat transfer surface, decreased flow due to reduced pipe diameters from corrosion deposits, and ultimately the need for system component replacement due to corrosion damage.

Corrosion is the chemical or electrochemical reaction between materials, usually a metal and its environment, which results in the deterioration of the metal and its properties. This article will cover chemical corrosion. (For more information on electrochemical or galvanic corrosion, please see our application note Avoiding Galvanic Corrosion.)Corrosion of metallic components is an inherent problem for water and water/glycol cooling systems because many metals naturally tend to oxidize in the presence of water. The dissolved oxygen in water accelerates most corrosion processes. In closed loop systems, the dissolved oxygen is consumed over time and no longer poses a corrosion risk. For open loop systems, however, the continued exposure to air allows oxygen to dissolve into the coolant. Therefore, open loop systems often suffer more corrosion problems compared to closed units. Corrosion is the chemical or electrochemical reaction between materials, usually a metal and its environment, which results in the deterioration of the metal and its properties. This article will cover chemical corrosion. (For more information on electrochemical or galvanic corrosion, please see our application note Avoiding Galvanic Corrosion.)Corrosion of metallic components is an inherent problem for water and water/glycol cooling systems because many metals naturally tend to oxidize in the presence of water. The dissolved oxygen in water accelerates most corrosion processes. In closed loop systems, the dissolved oxygen is consumed over time and no longer poses a corrosion risk. For open loop systems, however, the continued exposure to air allows oxygen to dissolve into the coolant. Therefore, open loop systems often suffer more corrosion problems compared to closed units.

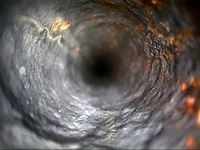

Corrosion is usually classified as either general or localized. General corrosion is the loss of metal uniformly distributed over an entire surface. It typically does not lead to rapid system failure because the rate of metal loss can be discovered before the metal ruptures. Localized corrosion, on the other hand, is not as predictable. It usually shows up in the form of pitting, which can penetrate into the metal very quickly, forming cavities or holes. Another common form of localized corrosion is cavitation, which occurs when pockets of vapor form in a liquid. This process occurs when the local pressure near the metal surface falls below the vapor pressure of the liquid. When these vapor bubbles collapse or implode, they generate large amounts of energy. This causes severe pitting to system components (such as pump), generates a great deal of noise, and results in a decrease in pump efficiency.

Potential corrosion problems

Corrosion can lead to many problems, the most significant being perforation that may result in coolant leakage. Other problems may include reduced heat transfer caused by surface scaling, which occurs when the metal reacts with oxygen, chloride, and/or inhibitors in the coolant and precipitates back to the metal surface, creating a layer that acts as a heat transfer barrier. Additionally, concerns include the clogging of particulate filters and damage to mechanical seals.

When copper corrodes, it is more often degraded by general corrosion than by pitting. General corrosion will often attack copper exposed to ammonia, oxygen, or fluids with high sulfur content. Another source of corrosion affecting copper is dissolved salts in the fluid, such as chlorides, sulfates, and bicarbonates.

For aluminum, pitting corrosion is the most common form of corrosion. Pitting is usually produced by the presence of halide ions, of which chloride (Cl-) is the most frequently encountered in liquid cooling loops. Pitting corrosion of aluminum in halide solutions open to the air occurs because, in the presence of oxygen, the metal is readily polarized to its pitting potential and the naturally occurring protective oxide layer or film is penetrated. This film is stable in aqueous solutions when the pH is between about 4.0 and 8.5. The film is naturally self-renewing and accidental abrasion or other mechanical damage of the surface oxide film is rapidly repaired. We strongly recommends an inhibitor when using water with aluminum to maintain a clean heat transfer surface.

Stainless steel is typically used in corrosive environments but, as with aluminum, it is sensitive to high concentrations of chlorides (>100 ppm) in an oxidizing environment. Pitting remains among the most common and damaging forms of corrosion in stainless steel alloys, but it can be prevented by ensuring that the material is exposed to oxygen and protected from chloride wherever possible. Stainless steels high in chromium, and particularly molybdenum and nitrogen, are more resistant to pitting corrosion.

Corrosion caused by uninhibited ethylene glycol

Studies1 show that uninhibited ethylene glycol will degrade into five organic acids - glycolic, glyoxylic, formic, carbonic, and oxalic - in the presence of heat, oxygen, and common cooling system metals such as copper and aluminum. Copper and aluminum act as a catalyst in the presence of uninhibited ethylene glycol. These organic acids will then chemically attack copper and aluminum in as little as three weeks under extreme conditions (212°F and oxygen bubbling into the uninhibited ethylene glycol solution) to form metal organic compounds in the fluid, which can lead to clogging of pipes, pumps, valves, etc.

Literature2 references often state that copper and aluminum are compatible with uninhibited ethylene glycol, but usually those recommendations are based on a two-week chemical compatibility study of various metals at different temperatures. The study above indicates that uninhibited ethylene glycol typically does not begin to degrade until after three weeks under those extreme conditions. In conclusion, the reported data is based on ethylene glycol's ability to dissolve the metal and ignores the concern of degraded, acidic uninhibited ethylene glycol and its effects on metals. The latter is much more corrosive towards metals.

Protecting against corrosion

In general, corrosion can be reduced through pH control and corrosion inhibitor use. The inhibitors attach to the metal surfaces to passivate them and prevent corrosion. It is also important to maintain a stable water flow to avoid stagnant zones inside the cooling system, which can cause corrosion.

Quality of water also needs to be considered when trying to prevent corrosion. The corrosive effect of natural water can vary considerably depending on its chemical composition. As mentioned earlier in this article, chloride is corrosive and use of tap water should be minimized or avoided if it contains more than 100 ppm of chloride. Hardness of water also needs to be considered because it introduces calcium and magnesium, which form scale on the metal surfaces. Deionized water, demineralized water, or water that has been passed through a reverse osmosis process to remove harmful minerals and salts is highly recommended in order to avoid chloride and scale buildup. A suitable corrosion inhibitor must be used with deionized or demineralized water.

There are different inhibitors for use with different metals, each with its advantages and disadvantages.

- Phosphate is an effective corrosion inhibitor for iron, steel, lead/tin solder, and most aluminum components. It is also a very good buffer for pH control. One disadvantage of phosphate is precipitation with calcium in hard water, which is one reason that deionized water is used for diluting a glycol/water coolant.

- Tolyltriazole is a common and highly effective corrosion inhibitor for copper and brass.

- Mercaptobenzothiazole also works for copper and brass, but it is not as stable as tolyltriazole.

- Nitrite is an excellent corrosion inhibitor for iron. At high concentrations, this inhibitor is corrosive to lead/tin solder.

- Silicate is an effective inhibitor for most metals but it tends to form thick deposits in cooling systems. The rust inhibitors in the automotive anti-freeze may cause premature failure of the pump seals.

- Chromate and soluble oils have been used in the past, but their use has greatly diminished due to their toxicity. Modern inhibitors have replaced them.

Summary

Although we can't stop corrosion all together, there are ways to significantly limit it. By selecting the proper fluid path materials, monitoring solution chemistry (specifically pH levels and water quality), and choosing the appropriate inhibitors, you can minimize the cost impact due to corrosion and ensure the effective operation of your liquid cooling loop for years.

1"Heading off Corrosion". Process Cooling & Equipment. @July/August 2002.

2"Technical Insights into Uninhibited Ethylene Glycol". Process Cooling & Equipment. @July/August 2002.

|