Selecting a Cooling System

Selecting a Cooling System: Ambient Cooling System | Recirculating Chiller | Liquid-to-Liquid Cooling System | Recirculating Chiller or Liquid-to-Liquid Cooling System | Selecting A Cold Plate Technology | Selecting A Pump | Selecting a Recirculating Chiller | Selecting Modular Cooling System | Selecting Liquid-to-Liquid Cooling System

Ambient Cooling Systems, Recirculating Chillers, Liquid-to-Liquid Cooling Systems.There are many different cooling technologies that selecting one can be a daunting task. This simple step-by-step guide explains the different types of cooling systems available and highlights how to select the right product for your application.

The first consideration is whether you need precise temperature control or need to cool below ambient (air) temperature. If you can answer 'no' to both of these, you are looking for a cooling system that will simply remove bulk heat. The most cost effective solution is an ambient cooling system.

Ambient Cooling Systems

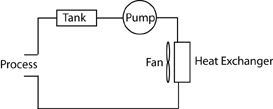

An ambient cooling system is the simplest and most economical cooling system. It contains a heat exchanger, fan, pump and tank, in a compact package. The pump circulates the fluid to your system and back through the heat exchanger, and the fan blows ambient air across the heat exchanger to cool the liquid.

There is no temperature control circuit, so an ambient cooling system does not maintain a pre-set temperature. Since the ambient air provides the cooling, the ambient temperature is the lower limit for the fluid exit temperature.

Figure 1 - Schematic of an Ambient Cooling System

Although they appear simple, ambient cooling systems are engineered for maximum capacity. The cooling system manufacturer's thorough understanding of heat exchanger performance allows the liquid flow rate and air flow rate to be performance-matched to extract the most cooling capacity from the system. The plumbing is designed for high reliability and components are carefully selected to avoid any galvanic corrosion issues. An off-the-shelf ambient cooling system is extremely easy to use - simply connect the fluid inlet / outlet fittings to your equipment, fill the tank and turn it on!

But what if you need to control the temperature or cool below room temperature? Recirculating chillers and liquid-to-liquid cooling systems are both good alternatives.

Recirculating Chillers

Recirculating chillers offer precise temperature control (within 0.1°C) and cooling below ambient temperature. They are quiet, cover a wide range of cooling capacities, and are available with many different options and additional features. Recirculating chillers are compact, quiet and easy to install.

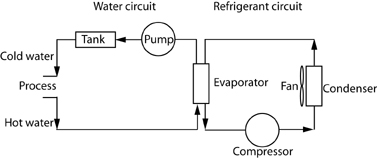

Recirculating chillers use refrigerant for cooling. They operate in a similar way to your refrigerator at home, except that they cool water instead of air. The process water circuit includes an evaporator, tank, and pump. The water is cooled by the refrigerant as it passes through the evaporator. On the other side of the evaporator the refrigerant evaporates to cool the water, then passes through a compressor and condenser, rejecting the heat to the ambient air.

Figure 2 - Schematic of a Recirculating Chiller

When heat loads get high, chillers can cause the room's air conditioning system to become overloaded as they reject the waste heat into the ambient environment. One option is to use a chiller with a liquid-cooled condenser. In this case, the refrigerant is cooled by facility-chilled water instead of air, making the chiller quieter and avoiding room-warming problems.

Another alternative for high heat loads is a liquid-to-liquid cooling system.

Liquid-to-liquid Cooling Systems (LCS)

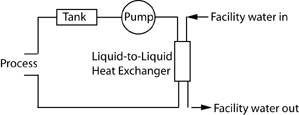

A liquid-to-liquid cooling system cools below ambient temperature and offers similar temperature stability to a recirculating chiller. Instead of rejecting the waste heat to the room, it transfers it to chilled facility water via a liquid-to-liquid heat exchanger.

The process side circuit is completely isolated from the facility water, protecting your equipment from fluctuations in temperature and flow rate of the facility water and any contaminants that may be present. Since the facility water provides the cooling, the facility water temperature is the lower limit for the fluid exit temperature.

Figure 3 - Schematic of a Liquid-to-Liquid Cooling System

Liquid-to-liquid cooling systems are popular for high heat load applications as they are compact - approximately 1/3 the size of a refrigerant-based chiller of similar capacity. Without a compressor, they are also very quiet and energy efficient.

Recirculating chiller or liquid-to-liquid cooling system?

For low heat loads, recirculating chillers are usually the simplest solution as installation is so easy. At high heat loads, liquid-to-liquid cooling systems are more cost effective. However, their use is restricted to situations where chilled facility water is available. The necessity to plumb them into facility water may affect the locations they can be used in and the portability of the equipment.

If you have high heat loads and need to reject the heat to facility water, the choice between an LCS and a recirculating chiller with a water-cooled condenser depends on your set-point temperature. If your set-point temperature is higher than your maximum facility water temperature, an LCS is more cost-effective. However, if you need to cool close to or below the facility water temperature, you will need a refrigerant based chiller with a water-cooled condenser.

Conclusions

Ultimately, the required cooling capacity, temperature stability, set-point temperature, and the availability of facility cooling water will dictate which system to use. For further assistance in choosing a cooling system, Lytron's interactive cooling system selector guides you through the options involved in selecting a system. Based on inputs such as your heat load and required flow rate, it will even recommend an appropriate product.

|