Selecting a Recirculating Chiller

Selecting a Cooling System: Ambient Cooling System | Recirculating Chiller | Liquid-to-Liquid Cooling System | Recirculating Chiller or Liquid-to-Liquid Cooling System | Selecting A Cold Plate Technology | Selecting A Pump | Selecting a Recirculating Chiller | Selecting A Modular Cooling System | Selecting an Liquid-to-Liquid Cooling System

Selecting the proper recirculating chiller is a function of four factors:

|

Figure 1: Recirculating Chiller RC022-RC045 Thermal Performance Curve |

|

Figure 2: Recirculating Chiller System Pump Curve |

- The heat load generated by the device being cooled (Q)

- The maximum acceptable temperature of the fluid exiting the heat source (TOUT)

- Available fluid flow rate (

) )

- Ambient operating conditions

Often, an equipment manufacturer will specify the set point temperature and flow rate of the required chiller. In this case, selecting a recirculating chiller is simple. Simply mark the intersection of the desired cooling capacity and the set point temperature on the chiller graph. Any chiller with a performance curve above or equal to this point will provide enough capacity. Next, use the pump graph to select a pump for your recirculating chiller which meets the desired flow rate.

Example 1:

A chiller needs to supply 2 gpm at 20°C to an x-ray tube that generates 2,000 W of heat. The power supply is 60 Hz. Marking this point on the chiller graph we can see that an RC022 would be an appropriate choice. From looking at the pump curves we see that a BE pump would provide the necessary flow rate.

If the Heat Load (Q) is known, but the Flow Rate is unknown, the following equation can be used to determine the required flow rate.

Example 2:

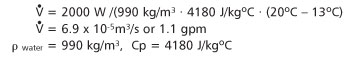

A laser head generates 2,000 Watts (6,824 BTU/Hr) of heat. The fluid temperature must not exceed 20°C (68°F). With a cooling fluid of water, 60 Hz power, at 20°C ambient, what is the appropriate recirculating chiller?

Using the thermal performance graphs (fig 1), draw a horizontal line at the required heat load (2000 W). As shown, the RC022 would match this requirement at 13°C (55°F). This is TIN (the temperature exiting the recirculating chiller). Therefore, the calculation then becomes:

Next, determine if the recirculating chiller can meet the required flow rate. As shown on the system pump graph (fig 2), the 1.3 gpm positive displacement pump would more than satisfy the flow requirement.

|