Selecting a Heat Exchanger Cooling Liquid

Selecting a Cooling System: Ambient Cooling System | Recirculating Chiller | Liquid-to-Liquid Cooling System | Recirculating Chiller or Liquid-to-Liquid Cooling System | Selecting A Cold Plate Technology | Selecting A Pump | Selecting a Recirculating Chiller | Selecting A Modular Cooling System | Selecting an Liquid-to-Liquid Cooling System

In order to select the correct heat exchanger or oil cooler, you must first determine the required thermal performance for your application. Use the example shown below:

Step 1: Application Data

| Liquid Type: |

Water |

| Required Heat Load (Q): |

3,300 W (11,263 BTU/Hr) |

| Temp. of Incoming Liquid (Tliquid in): |

80°C (176°F) |

| Temp. of Incoming Air (Tair in): |

21°C (70°F) |

| Rate of Liquid Flow: |

2 gpm (7.6 lpm) |

Step 2: Select the heat exchanger product series

Choose an aluminum, copper or stainless steel heat exchanger based on the fluid compatibility. Aluminum tubing is usually used with light oils, or ethylene glycol and water solutions. Copper is normally used with water. Stainless steel is used with deionized water or corrosive fluids.

Step 3: Calculate the initial temperature difference

Subtract the temperature of the incoming air from the temperature of the incoming liquid as it enters the heat exchanger.

| ITD |

= |

Tliquid in – Tair in |

|

= |

80°C – 21°C = 59°C or (176°F – 70°F = 106°F) |

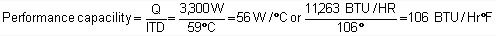

Step 4: Calculate the required performance capability (Q/ITD)

Divide the required heat load (Q) by the ITD found above in step 3.

Step 5: Select the appropriate heat exchanger model

Refer to the thermal performance graphs for the heat exchangers selected (See performance graphs for copper heat exchangers – 6000 series, copper heat exchangers – OEM Coils, stainless steel heat exchangers – Aspen Series, stainless steel heat exchangers – 4000 Series and oil coolers). Any heat exchanger that exceeds 56 W/°C at 2 gpm (using a standard fan) would be acceptable. As shown in the following graph, Lytron’s 6210 exceeds the required performance.

Step 6: Determine the liquid pressure drop

From the data given, we know our pump needs to supply water at 2 gpm. Using the liquid side pressure drop chart for the 6210 curve, the point where a vertical line at the 2 gpm point on the x-axis intersects with the 6210 curve reveals that the liquid pressure drop through the 6210 is 8 psi (0.55 bars). The pump selected must overcome this pressure drop to ensure a 2 gpm flow.

Step 7: Determine the air pressure drop

The vertical line on the thermal performance chart indicates the air flow rate (190 CFM for the Patriot fan) as provided by our standard fans at 60 Hz. The intersection point of this air flow rate and the 6210 graph on the air side pressure drop reveals that the air side pressure drop through the 6210 is 0.24 inches of water (55 pascals).

|