Lightweight Titanium Heat Exchanger for Airborne

In most aircraft cabin environmental control systems, bleed-air is cooled via a lightweight plate-fin heat exchanger using ram-air as the coolant. The high temperature of the hot bleed-air precludes construction from lightweight aluminum alloys, as they are generally only suitable for use up to approximately 400°F (204°C); stainless steel or nickel alloys (e.g. Inconel®) are generally the material of choice. Titanium heat exchangers offer a much higher performance to weight ratio than either of these materials. They can be operated at high temperature and are easily tailored to a given envelope.

Lytron, in conjunction with Material Resources International (MRi), and with SBIR funding1, has designed, developed, tested, and proven the manufacturing concepts for a titanium plate fin heat exchanger. It offers similar performance to stainless steel or nickel alloy heat exchanger at 30-50% less weight.

Design Specification

High performance, small size, and low weight are critical requirements for any airborne heat exchanger. For bleed-air cooling, the heat exchanger must additionally maintain its integrity at elevated temperature as the hot bleed air is typically in the 600°F-1000°F (316°C-538°C) range. It must also withstand the potentially high pressure (several hundred psi) on the bleed-air side of the exchanger without distortion, leakage, or failure.

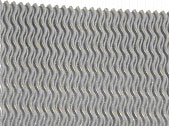

Fig. 2. Wavy titanium fin Fig. 2. Wavy titanium fin Heat Exchanger Design

Lytron designed the heat exchanger based on the stringent performance, dimensional, and weight specifications required for a typical bleed air engine application.

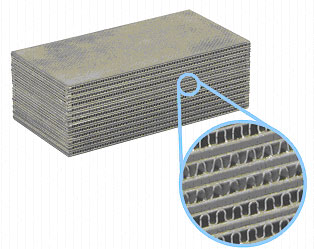

The plate fin design consists of folded fin layered in alternate directions, with side rails to complete the loop (Fig. 1). Wavy fin was selected as it has good thermal transfer properties, and is practical to manufacture from titanium. Alternatives such as lanced offset fin are difficult to make due to the material properties of the titanium. The geometric dimensions meet the envelope specifications and the number of passes was designed for optimal heat transfer.

Fig. 3. Titanium heat exchanger core showing close-up of fin Fig. 3. Titanium heat exchanger core showing close-up of fin Development of Manufacturing Concepts

Lytron investigated a variety of titanium alloys. C.P. Ti Grade 4 was selected for the fin stock and tube plate. This is a commercially pure titanium alloy with high tensile and yield strengths. Wavy fin was manufactured at Lytron using a Robinson fin machine with a custom fin-folding die (Fig. 2).

Braze fillers of various material compositions and forms (pastes, foils, and powders) were evaluated. A pre-alloyed titanium powder developed by MRi provided the highest quality braze joints. Several methods of application were tested and a suspension spray method yielded the most even coverage.

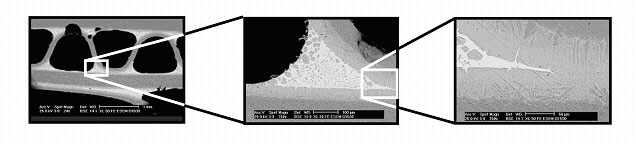

The heat exchanger cores produced using spray-applied titanium alloy braze material showed excellent joining at all observable edges and internal fin-plate joints, and there was no plugging of passages (Fig. 3.) Tensile pull, lap shear, and burst tests demonstrated good consistency in braze strengths. Metallographic cross sections of the various fin-plate joints showed that the structure of the braze joint was sound with no voiding (Fig. 4). As with all plate-fin heat exchangers, well designed braze fixtures are critical to ensuring high quality brazed joints and good yields from the vacuum brazing process.

Lytron experimented with various header designs and methods of attachment. The best results were achieved with a header that was directly welded in a glove box.

Fig. 4. Microphotographs of cut (EDM) core made with folded-wavy Grade 4 titanium fin braze joined to tube sheet with a Ti alloy

Fig. 5. Titanium heat exchanger

Testing and Validation

Thermal Performance

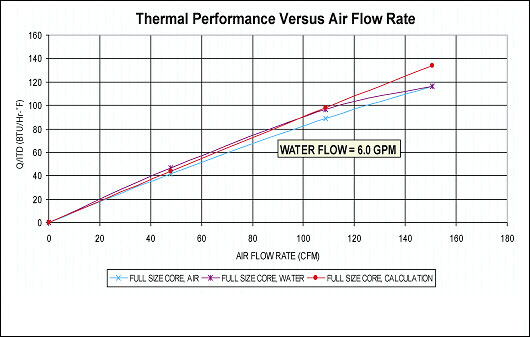

Lytron built several titanium plate-fin heat exchangers (Fig. 5) and tested them over a range of conditions. These results were compared to the thermal model to verify its accuracy. For ease of laboratory testing, the bleed air heat exchanger was tested as a water/air heat exchanger (water on the hot side) rather than an air/air heat exchanger. Measured results were compared to predicted results (Fig. 6). These results validated the predicted performance for a range of Reynold's numbers. They also enabled the difference between measured and calculated values to be quantified and the theoretical model further refined.

Fig. 6. Comparison of actual to predicted heat exchanger thermal performance with air flow rate. Water flow rate = 6.0 gpm (performance was also measured at 4gpm and 8 gpm)*

Based on these results, it is predicted that the heat exchanger meets or exceeds the original design specification at the elevated temperatures and pressures that would be found in a typical bleed-air to ram-air heat exchanger application.

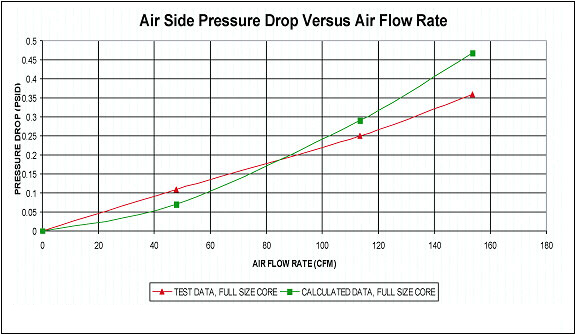

Pressure Drop Performance

Fig. 7. Air side Pressure Drop

Pressure Testing

All samples held a proof pressure of 800 PSI. One was tested to burst pressure. It burst at 1500 PSI where it leaked along the seam between the header and the bar.

Size and Weight

The heat exchanger weighs just 2 lbs. 14½ ounces and measures 7.5" x 3" x 2.125" including headers.

Summary

Lytron has designed and built prototype titanium heat exchangers for bleed-air to ram-air cooling. These demonstrated excellent correlation to predicted results in laboratory scale performance tests and are predicted to meet or exceed the performance specifications to which they were designed. The heat exchangers also passed all laboratory reliability tests including tensile testing, pressure testing, and burst testing.

Further Development

Lytron has developed the design and manufacturing skills, as well as the manufacturing infrastructure and qualified material sources to produce titanium heat exchangers. To move forward with this technology, Lytron is seeking military and/or commercial partners to assist in fabricating a 'flight-worthy' titanium plate fin heat exchanger and to install titanium plate fin heat exchangers onto aircraft for more extensive testing.

|