Physical Properties of HDG Hot-Dipped Galvanized

The superior corrosion protection provided by hot-dip galvanizing is the most important reason for specifying zinc coating. However, some other factors have an impact on the appearance and use of galvanized steel.

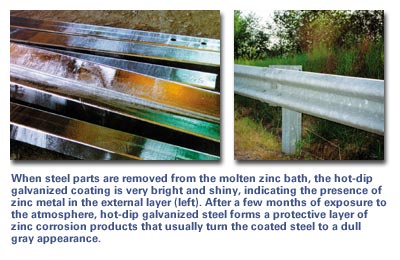

Galvanized coating are generally bright and shiny but within a year will weather to a uniform dull gray appearance. The basic finish requirements of the galvanized coating are that it be relatively smooth, continuous, and free from gross surface imperfections. Smoothness is an ambiguous term; the product’s end use must be the determining factor in setting tolerances for smoothness. The galvanized coating is continuous and provides optimum corrosion protection.

Handling techniques for galvanizing may require the use of chain slings, wire or other holding devices to lower material into the galvanizing kettle if suitable lifting features are not available on the item. Chains, wires, and special jigs used to handle the items may leave a mark on the galvanized item. These marks are not detrimental to the coating, nor are they cause for rejection. If considered necessary, or expose bare steel, these areas can be easily touched up using the procedures described in ASTM A 780.

Differences in the luster and color of galvanized coatings do not significantly affect corrosion resistance. The presence or absence of spangle has no affect on coating performance. The well-known spangled effect found on galvanized products is a crystallization process that is dependent upon the zinc bath chemistry, the rate of cooling, the method of pickling, the steel chemistry, and the thickness of the coating. Dull gray or patchy matte gray galvanized coatings give a service life equal to bright or spangled coatings since the service life depends on the zinc coating thickness. Variations in coating appearance or finish are important only to the extent that they will affect the intended use of the article. The primary function of the galvanized coating is corrosion protection.

Related References:

1. About Zinc

2. About Hot-Dip Galvanizing

3. HDG Hot-Dip Galvanizing Last Time

4. Cost of Galvanized Steel

5. Selection of Zinc Coatings

6. Zinc Coatings-Galvanized|Electrogalvanized|Galvanneal|Galfan

7. Physical Properties of HDG Hot-Dip Galvanized

8. HDG Hot-Dip Galvanized Abrasion Resistance Resistance to Mechanical Damage

9. Hot-Dip Galvanized Corrosion Protection and the Zinc Patina

10. HDG Hot-Dip Galvanized High Temperature Exposure

11. HDG Hot-Dip Galvanized Surface Reflectivity

12. HDG Hot Dip Galvanized Coating Structure

13. HDG Hot Dip Galvanized Bond Strength

14. HDG Hot Dip Galvanized Coating Uniformity

15. HDG Hot Dip Galvanized Coating Thickness

16. Powder Coating Hot Dipped Galvanized Steel

17. Painting Hot-Dippped Galvanized Steel

18. Painting Hot-Dipped Galvanized Steel Surface Preparation

19. Surface Coatings for Corrosion

20. Hot-Dip Galvanizing Surface Preparation

21. Hot-Dip Galvanizing Galvanizing

22. Hot-Dip Galvanizing Inspection

23. Characteristics of Zinc

24. Hot-Dip Galvanizing Performance in Atmosphere

25. Hot-Dip Galvanizing in Atmosphere Time to First Maintenance

26. Hot-Dip Galvanizing Performance in Soil

27. Soil Corrosion Data for Corrugated Steel Pipe

28. Hot-Dip Galvanizing Performance in Water

29. Cause of Zinc Corrosion

30. Corrosion of Zinc Coated Steel in Selected Natural Fresh Water

31. Corrosion of Zinc and Zinc Coated Steel in Sea Water

32. Corrosion of Zinc Coating in Industrial and Domestic Water

33. Concrete Corrosion of Hot Dip Galvanizing

34. Concrete corrosion resistance of hot dip galvanized reinforcing

35. Removal of Forms Concrete Corrosion

36. Zinc Reaction in Concrete Corrosion

37. Concrete Corrosion References

38. Hot-Dip Galvanizing Performance in Chemical Solutions

39.Hot-Dip Galvanizing Performance in Contact with Other Metals

40. Hot-Dip Galvanizing Performance in contact with Treated Wood

41. Hot-Dip Galvanizing Performance in contact with Food

42. Hot-Dip Galvanizing Performance in Extreme Temperature

|