How to Repair the deviate of U Bent Tubes Shaping in U Parts - Flatten | Ball Passing Test

Permissible variations from the specified outside diameter

shall be in accordance with Specification A 1016/A 1016M. Those tolerances do not apply to the bent portion of the U-tubes. At the bent portion of a U-tube for R = 2 3 D or greater, neither the major nor minor diameter of the tube shall deviate from the nominal diameter prior to bending by more than 10 %. If less than 2 3 D is specified, tolerances could be greater.

Permissible Variations from the Specified Wall Thickness:

Permissible variations from the specified minimum wall thickness shall not exceed +20 % − 0.

Permissible variations from the specified average wall thickness are 610 % of the nominal wall thickness.

The end of any tube may depart from square by not more than the amount given in Table 4. The leg spacing measured between the points of tangency of the bend to the legs shall not vary from the value (2 R − specified tube outside diameter) by more than 1⁄16 in.[1.5 mm] where R is the center-line bend radius.

The bent portion of the U-tube shall be substantially uniform in curvature, and not to exceed 61⁄16 in. [1.5 mm] of the nominal center-line radius. Permissible deviation from the plane of bend (Fig. 1) shall not exceed 1⁄16 in. [1.5 mm] as measured from the points of tangency.

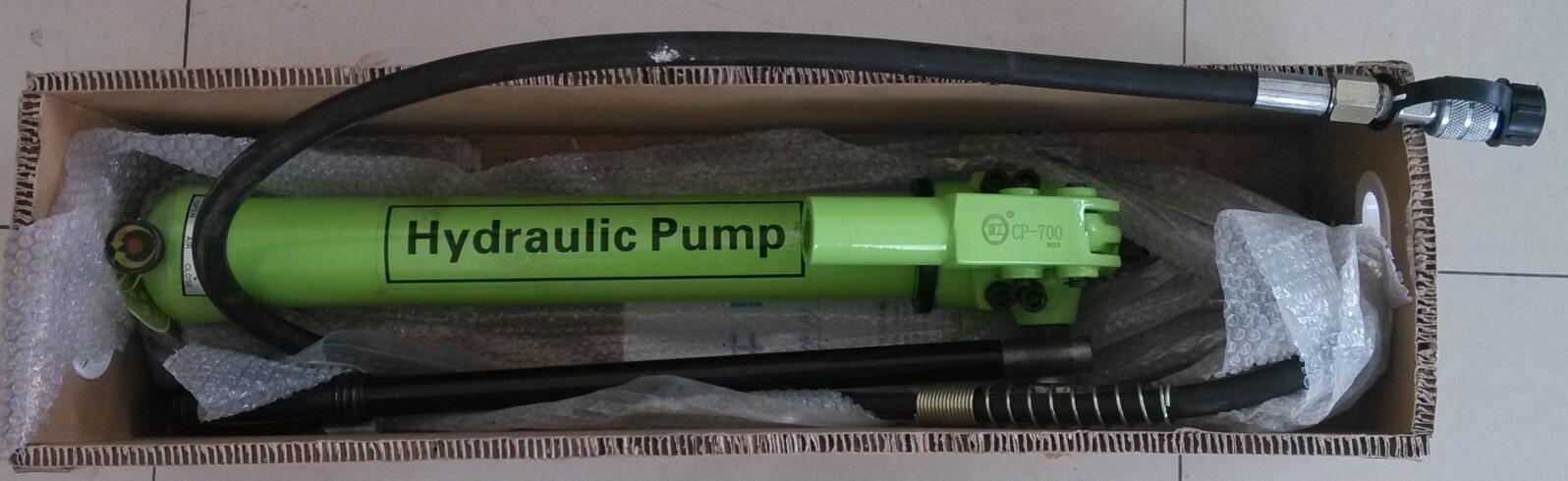

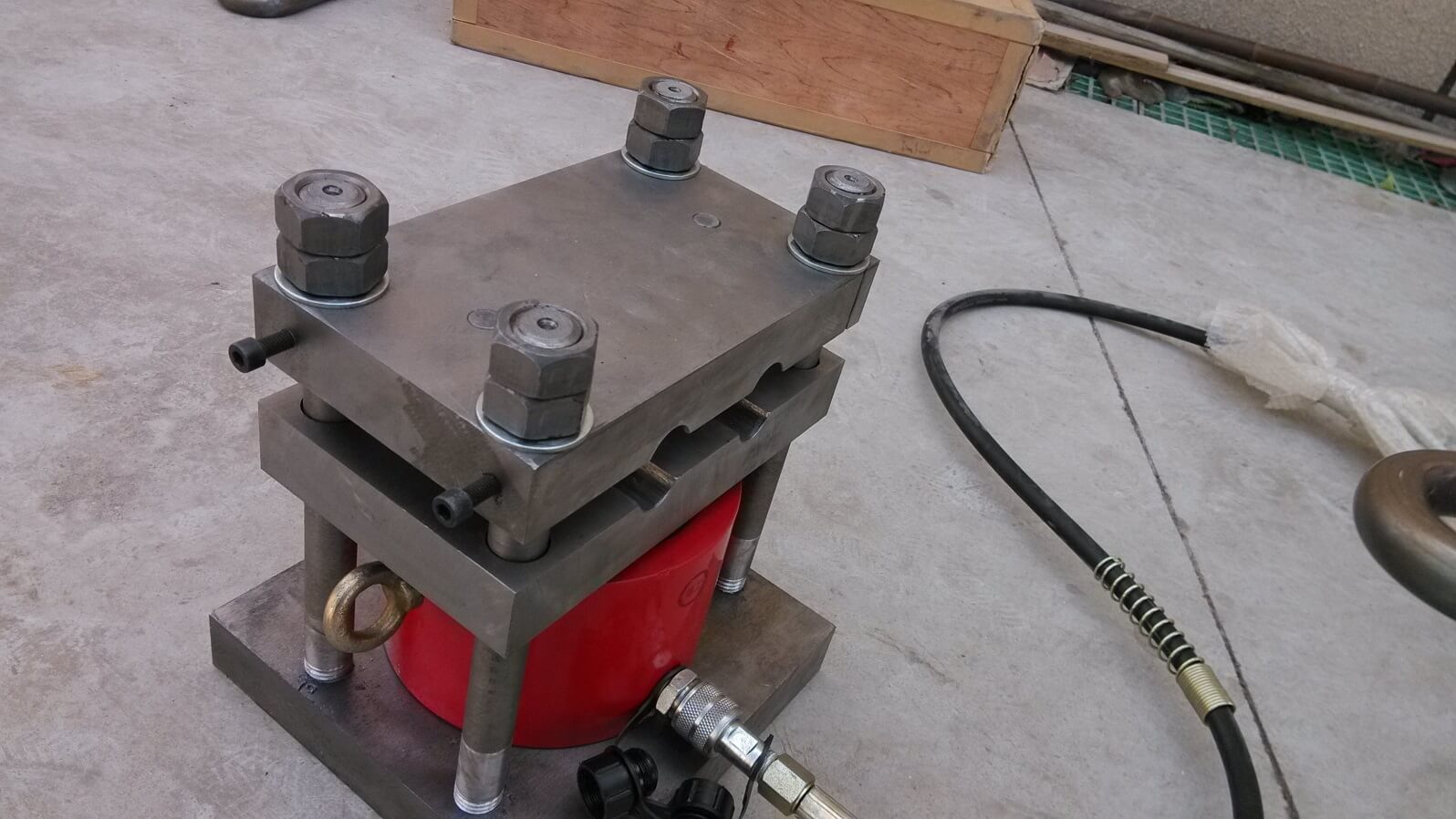

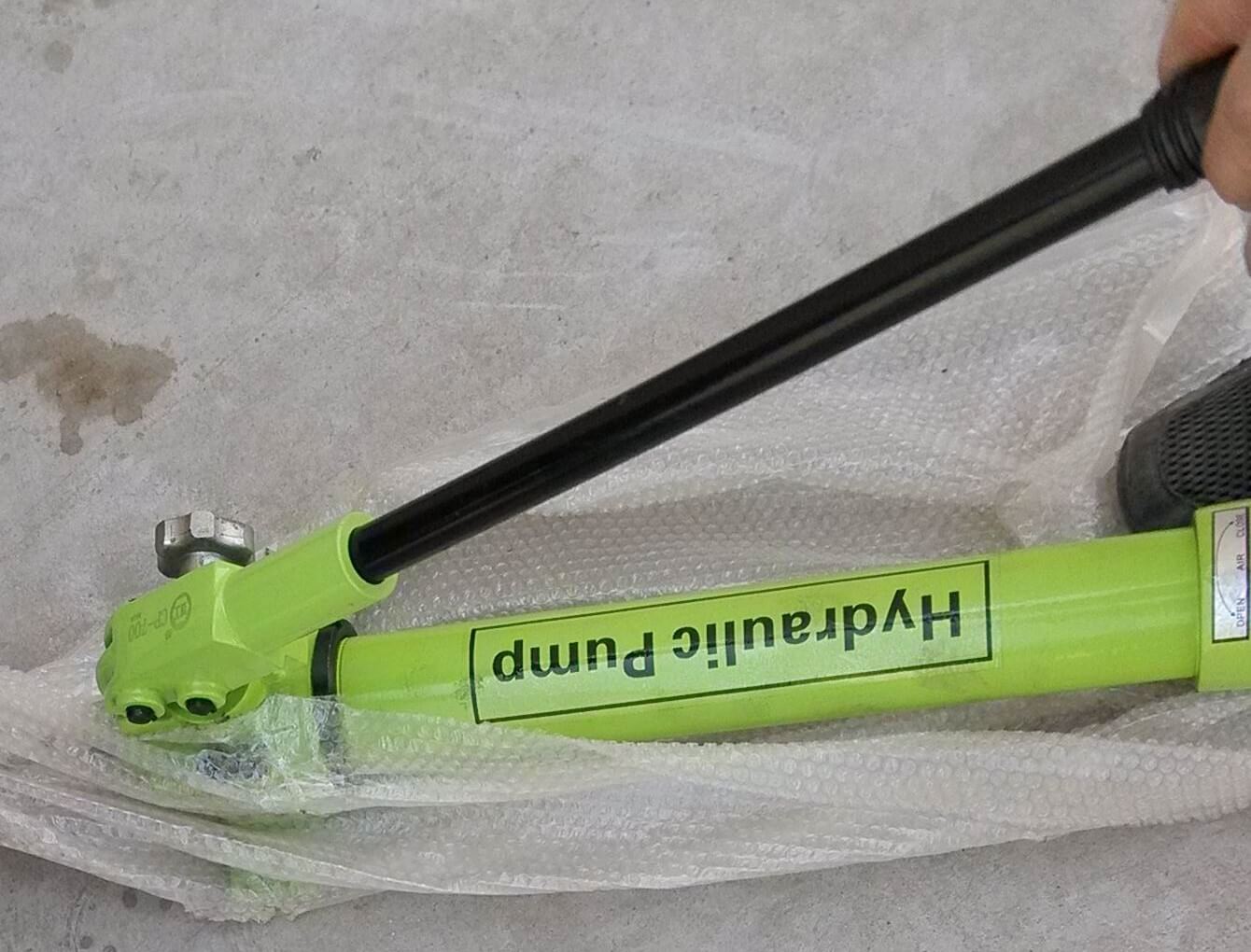

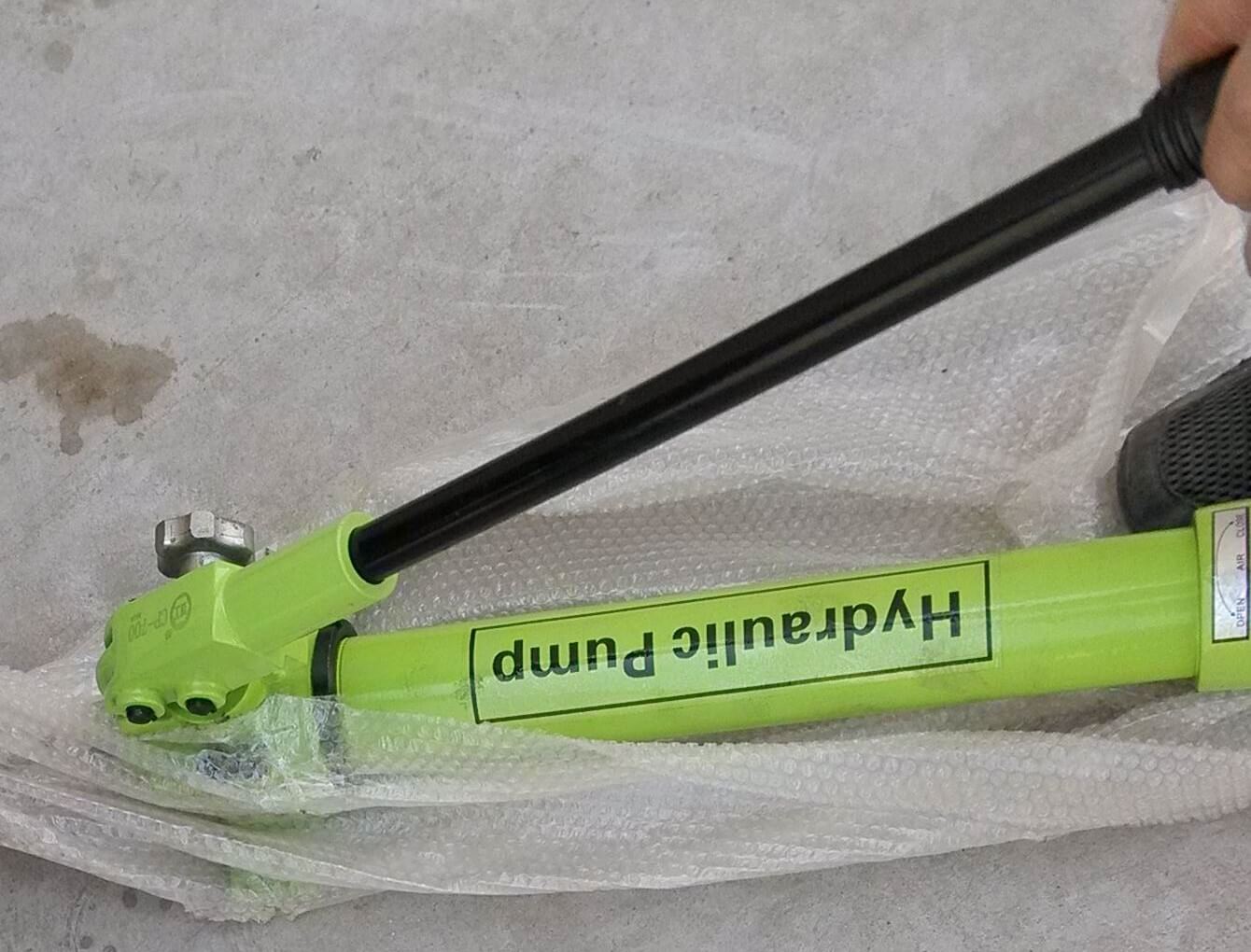

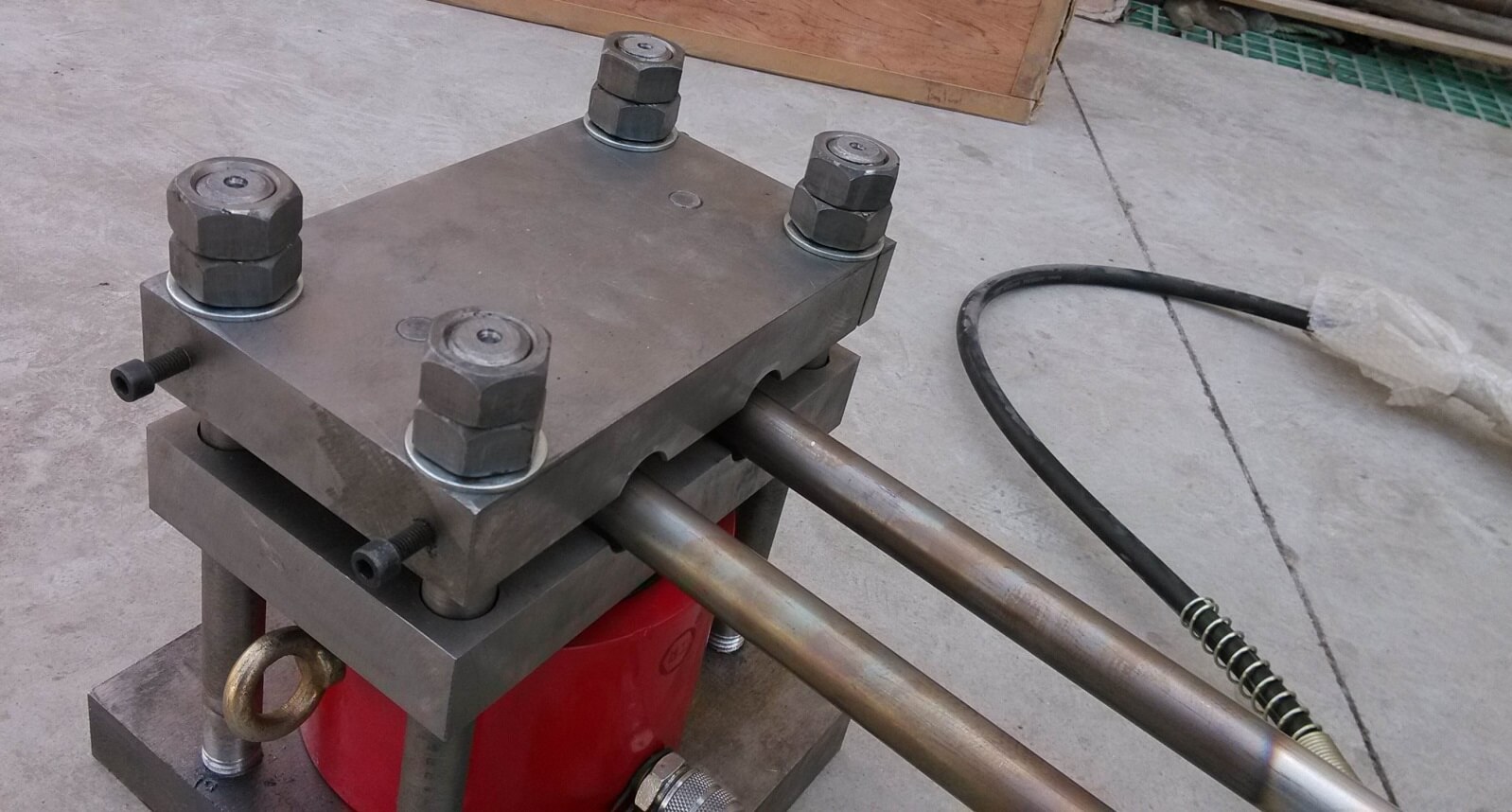

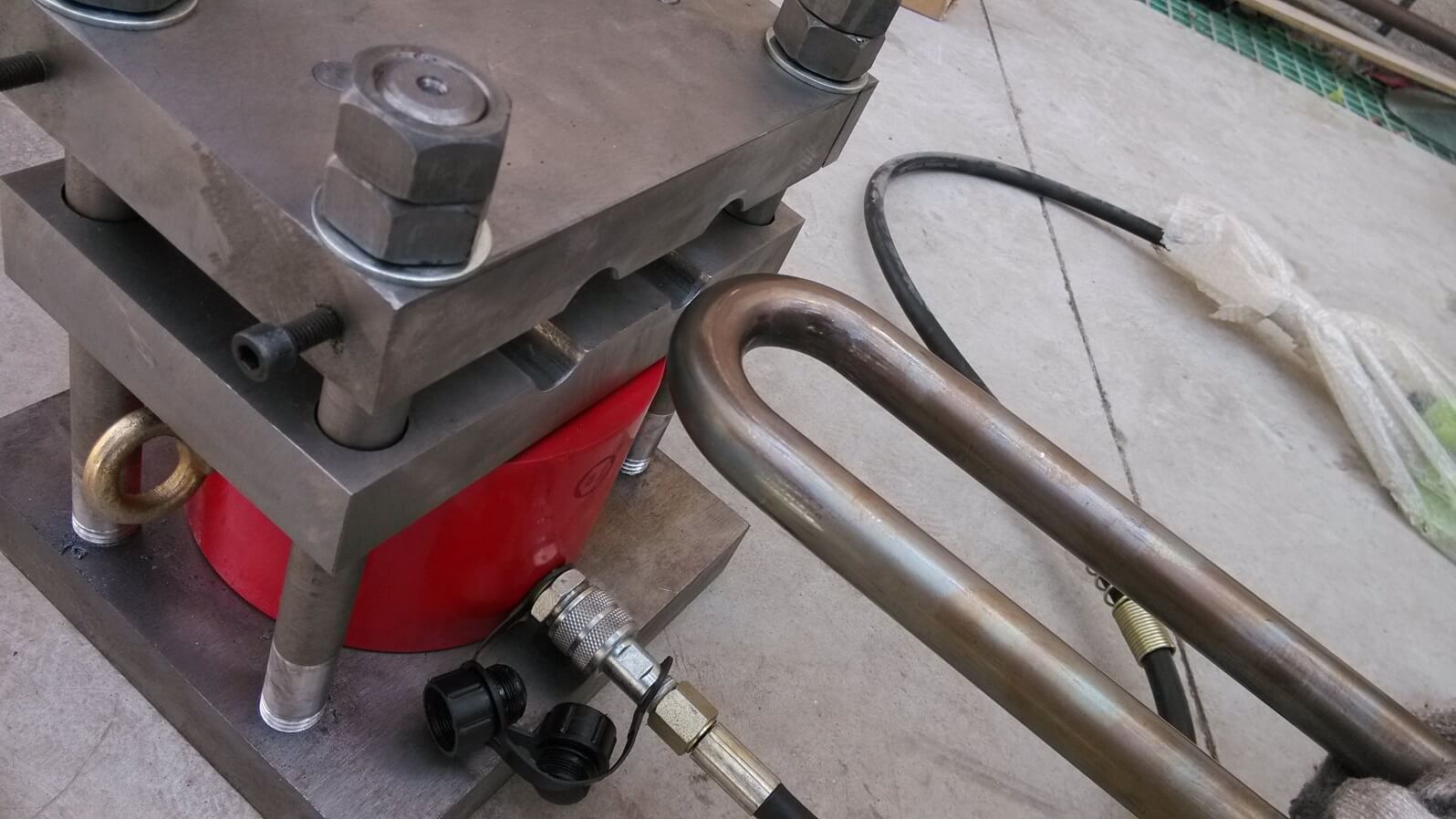

The shaping equipment consist of three parts:

1) Hydraulic Pump; 2) Hydraulic Cylinder; 3) Mechanical Parts (Mould)

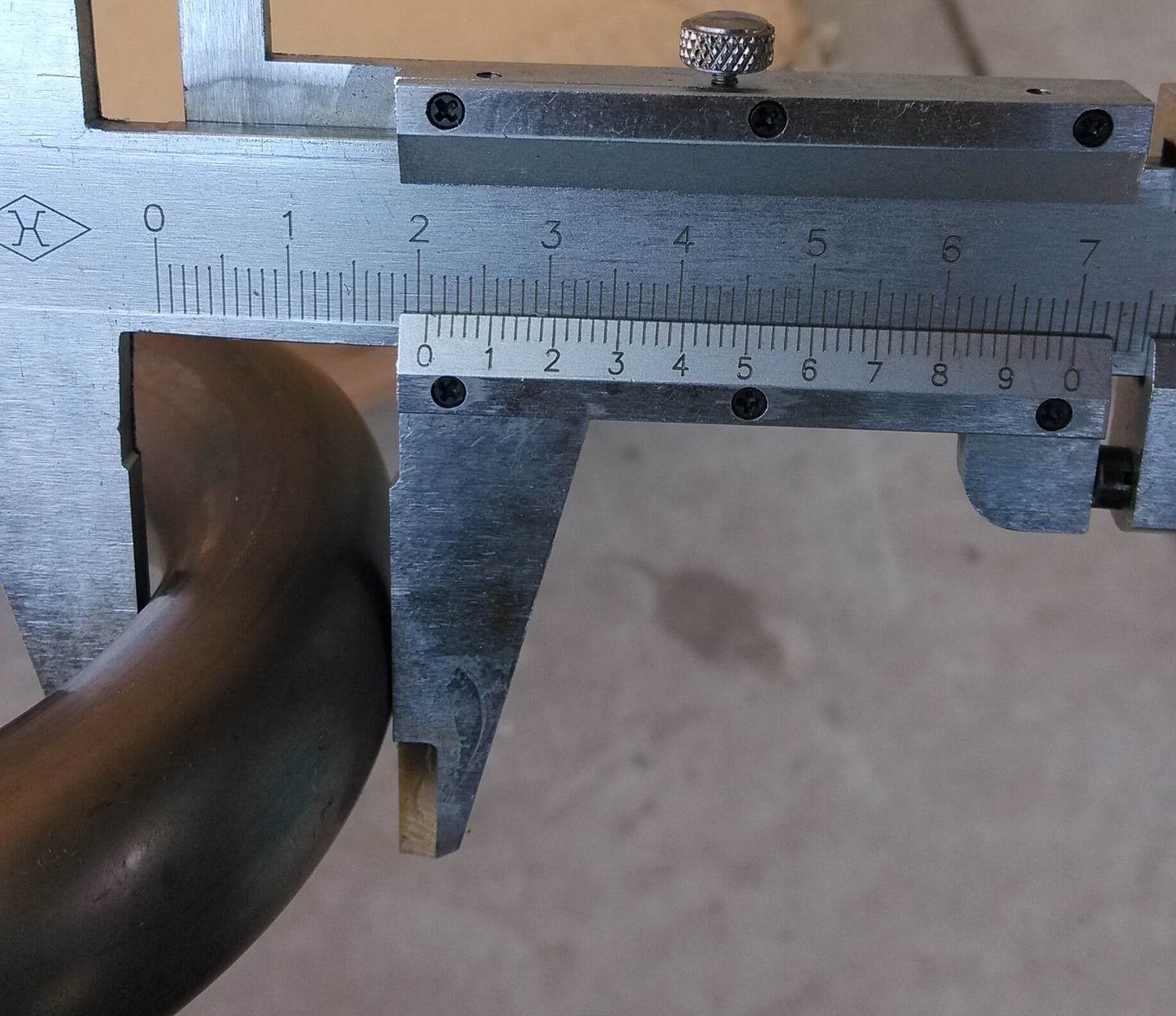

2. The testing stainless steel tubes specimen Radius = 38.1mm, OD=25.4mm, Wall thickness=2.11mm

3. The specimen stainless steel tube’s minimum outside diameter on U parts before shaping is 20.8mm

Shaping Steps:

1. Put the hydraulic cylinder into the mechanical parts. And connect the hydraulic pump with the hydraulic cylinder.

Notice: Please screw up!

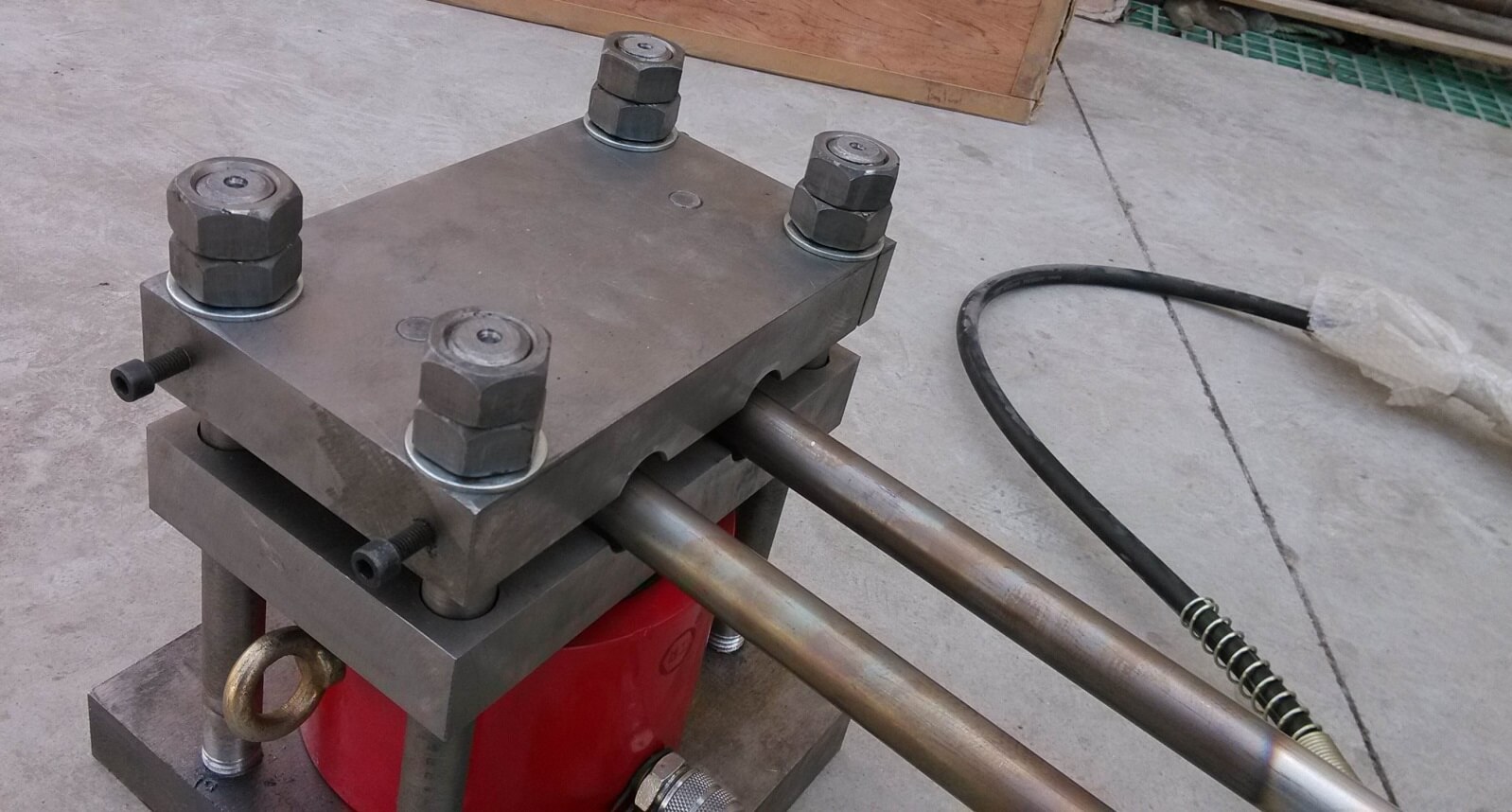

2.Put the U bend stainless steel tubes into the mechanical parts mould.

3.Tighten the argent screws of hydraulic pump. Manual operated the hydraulic pump.

4.When the mould gap turn into about 5mm, then finished. We use a red skin to test.

5.Loosen the argent screws of hydraulic pump.

6.Then the pressure of hydraulic cylinder disappears.

7.Take the U bend stainless steel tubes out.

8.The specimen stainless steel tubes outside diameter on U bend parts shaped to 23.8mm now.

Notice: Because of long distance of transport. Please tighten again the 4 screws top of the mould.

Related References:

|