1.2344 Tool Steel

1.2344 X40CrMoV5-1 BS4659 BH13 is an air hardening hot work tool steel which combines a very good red-hardness with toughness and covers a wide variety of applications. 1.2344 X40CrMoV5 hot work tool steel can be water cooled in service and offers high temperature strength and wear resistance

1.2344 is one of the hot work, chromium type tool steels. It also contains molybdenum and vanadium as strengthening agents. The chromium content assists this alloy to resist softening if used at higher temperatures. Secondary hardening steels with good tempering reistance. It maintains high hardness and strength at elevated temperatures. Good resistance to thermal fatigue, erosion and wear. Steel with very high thoughness and good ductility and hardenability. Tools can be water cooled.

1.2344 H13 finds applications for hot die work, die casting and extrusion dies, wear resisting tools, pressure die casting tools, pressing tools for light and heavy metal.

Forging : Heat slowly and uniformly to 700°C. Forge 1.2344 within a range of 1050/1150°C reheating if necessary, since forging must not be carried out below 850°C. Cool slowly, preferably in a furnace since this is an air hardening steel.

Annealing: Heat uniformly to 750/800°C, soak thoroughly and furnace cool.

Stress Relieving: After rough machining the 1.2344 components must be stress relieved, heat to 650/700°C and hold for 2 hours then furnace cool.

Hardening: Pre heat the 1.2344 to 750/850°C and soak thoroughly, then increase rapidly to the hardening temperature of 1000/1030°C in a controlled atmosphere or neutral salt bath. Cool in air.

This steel is suitable for vacuum hardening.

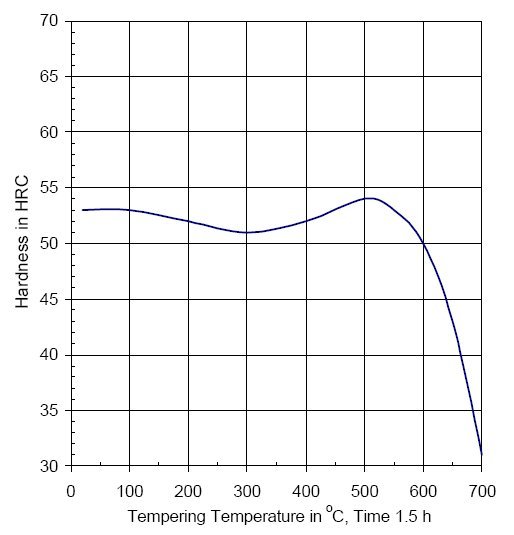

Tempering: Heat uniformly and thoroughly at the selected tempering temperature, depending on the hardness requirement. Hold for at least two hours per inch of total thickness and cool in air. Double tempering of 1.2344 is strongly recommended

| Chemical Composition |

|

|

|

| C. |

Si. |

Mn. |

Cr. |

Mo. |

V. |

| 0.38% |

1.00% |

0.40 |

5.00% |

1.30% |

1.00% |

| Tempering °C |

400 |

500 |

550 |

600 |

650 |

| HRc |

54 |

56 |

54 |

49 |

47 |

Tufftriding: Tufftriding 1.2344 hot work tool steel is done in a special salt bath at 570°C. Holding time 2 hours. It gives a surface hardness of approximately 950-1000HV.

Nitriding: Nitriding 1.2344 hot work tool steel gives a hard surface case which is very resistant to wear and erosion and also increases the corrosion resistance. Nitriding in ammoniac gas at 525°C gives a surface hardness of approximately 1000HV 1250HV. Before nitriding, the tool should be hardened and tempered at approximately 50°C above nitriding temperature.

| Temperature |

Time |

Approximate Depth of Case |

| 525°C |

10 hours |

0.125mm |

| 525°C |

20 hours |

0.180mm |

| 525°C |

40 hours |

0.250mm |

| 525°C |

60 hours |

0.300mm |

Welding:

Due to the high risk of crack formation welding of 1.2344 tool steel should be avoided, if possible. When, howe ver welding is essential, the following serves as a guide:

A . Welding of soft annealed 1.2344 X40CrMoV5< tool steel

· Preheat to 300 - 500°C

· Weld at 300-500°C

· Immediately stress relieve at 675-750°C. Soaking time at temperature, 3 hours.

Electrode: Cr-Mo alloy electrode for welding low alloyed steel.

B. Welding in connection with hardening of soft annealed 1.2344 X40CrMoV5 tool steel.

· Heat to austenitizing temperature.

· Cool to approx. 500°C

· Weld at approx. 500°C

· Cool to approx. 100°C in the same way as at normal hardening, then temper to desired hardness.

Electrode: Hard facing electrode.

C. Repair welding of 1.2344 X40CrMoV5 tool steel in hardened and tempered condition.

· Preheat to the tempering temperature (min. 300°C) previously used.

· Weld at tempering temperature. Do not weld below 150°C.

· Reheat immediately to 300°C. Soaking time 3 hours.

· Cool in air to approx. 80°C.

· Reheat immediately to 300°C. Soaking time 3 hours.

Electrode: Hard facing electrode.

Physical properties (avarage values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 215

Density [g/cm3]: 7.78

Thermal conductivity [W/m.K]: 25.0

Electric resistivity [Ohm mm2/m]: 0.52

Specific heat capacity[J/g.K]: 0.46

Thermal conductivity [W/m.K]M

| 20°C |

500°C |

600°C |

| 25 |

28.5 |

29.3 |

Density [g/cm3]

| 20°C |

500°C |

600°C |

| 7.78 |

7.64 |

7.60 |

Electric resistivity [Ohm mm2/m]

| 20°C |

500°C |

600°C |

| 0.52 |

0.86 |

0.96 |

Specific heat capacity[J/g.K]

| 20°C |

500°C |

600°C |

| 0.46 |

0.55 |

0.59 |

Coefficient of Linear Thermal Expansion 10-6 °C-1

| 20-100°C |

20-200°C |

20-300°C |

20-400°C |

20-500°C |

20-600°C |

20-700°C |

20-800°C |

| 10.7 |

11.9 |

12.2 |

12.5 |

12.7 |

13.1 |

13.5 |

13.7 |

Continuous Cooling Transformation (CCT) Diagram

Soft Annealing

Heat to 760-810°C, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

Hardening

Harden from a temperature of 1020-1060°C followed by oil, air quenching or warm bath (450-550°C). Hardness after quenching is 52-56 HRC.

Tempering

Tempering temperature: See the diagram bellow.

Tempering Temperature (°C) vs. Hardness (HRC) vs. Tensile Stregth (N/mm2)

| 100°C |

200°C |

300°C |

400°C |

500°C |

550°C |

600°C |

650°C |

700°C |

| 53 |

52 |

51 |

52 |

54 |

53 |

50 |

43 |

31 |

| 1845 |

1790 |

1730 |

1790 |

1910 |

1845 |

1680 |

1360 |

995 |

Tempering Diagram

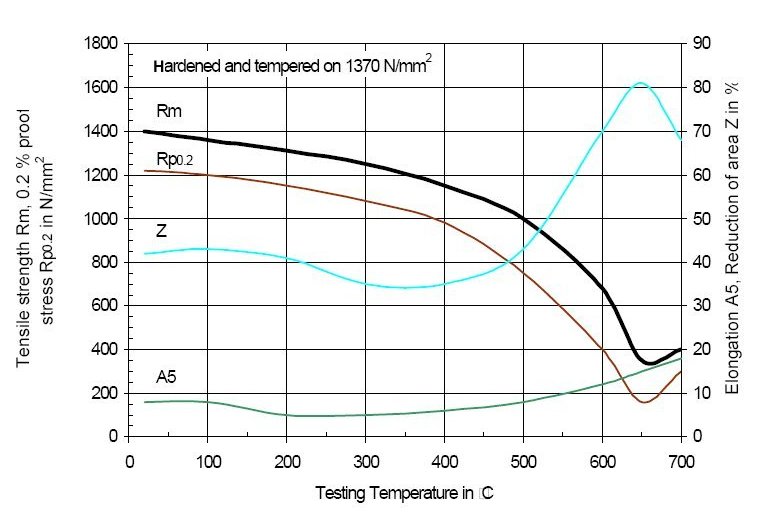

Diagram Tempering Temperature - Mechanical Properties

| Physical Properties: 1.2344 X40CrMoV5 |

Temperature: |

|

|

| |

200°C |

400°C |

600°C |

| Density (Kg/dm³) |

7.75 |

7.70 |

7.65 |

| Coefficient of thermal expansion (per °C from 0°C) |

11.9 x 10-6 |

12.4 x 10-6 |

12.8 x 10-6 |

| Thermal conductivity (cal/cm.s °C) |

60.0 x 10-3 |

62.4 x 10-3 |

63.6 x 10-3 |

| Modulus of elasticity: |

|

|

|

| N/mm² |

184 000 |

175 000 |

154 000 |

Pipes Tubes Plates Bars Square Tubes Weight Calculation Calculator

Pipe Working Pressure Calculation

Conversion Calculator Calculation-Pressure|Weight|Temperature|Volume|Length

Conversion Table-Pressure|Stress|Mass|Length|Temperature|SI Prelxes

Metals Weight Calculator-Aluminum|Brass|Bronze|Copper|Magnesium|Plastic|Nickel|Steel|Titanium|Zinc

1.2080|1.2083|1.2311|1.2344|1.2363|1.2379|1.2436|1.2510|1.2550|1.2767|1.2842|1.3343

AISI O1|AISI W1|AISI D2|AISI D3|AISI D6|AISI A2|AISI H13|AISI S1|AISI S7|AISI P20|AISI M2|AISI M42

1008|1010|1015|1018|1020|1025|1035|1040|1045|1050|1117|1141|1144 | 12L14|1215 | 4140 | 4150 | 4340 | 8620 | A36|A653|A513

|