Biofouling Resistance

Copper-nickel alloys have a high inherent resistance to macrofouling. This reduces the frequency of cleaning of piping systems and condenser, and decreases wave loading and fouling removal costs for platform structures. Also, the down time and expense of applying antifouling coatings to boat hulls is avoided and fuel consumption is improved. Fouling that does form is poorly adherent and thus easily removed.

The biofouling resistance of copper-nickel tubing allows shipboard condensers to maintain good heat transfer capability for several months between mechanical cleanings without the need for onboard chlorine generators required for other tubing materials.

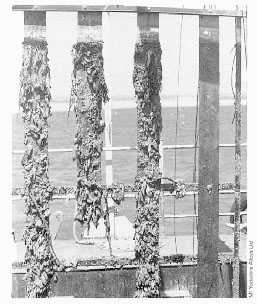

The most important requirement for optimum biofouling resistance is that the alloy should be freely exposed or electrically insulated from less noble alloys or free of cathodic protection as shown in Figure 4.

FIGURE 4. Exposure Panels. Panels after 12 months exposure at Langstone Harbour, UK. Left to right: Steel, 90-10 Copper-Nickel Sheathed Steel, Copper-Nickel; all products with aluminum anodes. Far right: unprotected copper nickel. There is no fouling on the unprotected Copper-Nickel.

FIGURE 4. Exposure Panels. Panels after 12 months exposure at Langstone Harbour, UK. Left to right: Steel, 90-10 Copper-Nickel Sheathed Steel, Copper-Nickel; all products with aluminum anodes. Far right: unprotected copper nickel. There is no fouling on the unprotected Copper-Nickel.General observations have led to the understanding that for open seawater exposures, such as experienced on ship hulls or offshore splash zone sheathing, the slime layers (microfouling) do not build up sufficiently to support macrofouling. When exposed to long periods under quiet conditions, some macrofouling will eventually occur but this has been observed to slough away at intervals.

It is generally thought that the 70-30 copper-nickel alloy has less biofouling resistance than the 90-10 alloy, having a lower copper content, but this is not always borne out in practice. The longest running copper-nickel yacht, the Asperida has given trouble free service since 1968 and it has a 70-30 hull. Fourteen year exposure for 70-30 test panels under quiet, tidal and flowing conditions at the LaQue Corrosion Services, Wrightsville Beach, North Carolina, showed negligible fouling after that time. Five year exposure data under quiet conditions, again at the Wrightsville Beach site, showed the response to fouling to be the same whether the alloy exposed was 90-10, 70-30 and unalloyed copper itself.

The copper-nickels in the same trials were found to corrode at one third of the rate of the copper. 70-30 copper-nickel welds occasionally prove preferential sites for fouling compared with the 90-10 base material. However, the welds are slightly more noble than the 90-10 and there may be a galvanic influence on the biofouling resistance of the welds. More detailed examinations are required to explain this. Currently, it suffices to say that any differences in biofouling properties of 90-10 and 70-30 alloys would appear to be of little practical significance for hulls and offshore platform splash zone sheathing.

Copper Nickel for Seawater Corrosion Resistance and Antifoulin

90-10 and 70-30 Copper-Nickel Alloys

Corrosion Resistance

The Importance of the Surface

General Corrosion Rates

Localised Corrosion

Velocity Effects

Sand Erosion

Galvanic Properties

Handling Sulfides

Ferrous sulfate treatment

Biofouling Resistance

Ease of Biofouling Removal

Reasons for Biofouling Resistance

Boat Hull Experience

Offshore Sheathing

Conclusions

|