S32205 S31803 1.4462 Resistance to Corrosion

2205 duplex stainless steel is a cost effective solution for many applications where the 300 series stainless steels are susceptible to chloride stress corrosion cracking. Stress corrosion cracking occurs when stainless steels are subjected to tensile stress, while in contact with solutions containing chlorides. Increasing temperatures also increase the susceptibility of stainless steels to stress corrosion cracking.

The combination of chromium, molybdenum and nitrogen convey the good resistance of 2205 to chloride pitting and crevice corrosion. This resistance is extremely important for services such as marine environments, brackish water, bleaching operations, closed loop water systems and some food processing applications. The high chromium, molybdenum and nitrogen contents of 2205 provide corrosion resistance superior to common stainless steels, such as, 316L and 317L in most environments.

General Corrosion

Because of its high chromium (22%), molybdenum (3%), and nitrogen (0.18%) contents, the corrosion resistance properties of 2205 are superior to that of 316L or 317L in most environments.

Localized Corrosion Resistance

The chromium, molybdenum, and nitrogen in 2205 also provide excellent resistance to pitting and crevice corrosion even in very oxidizing and acidic solutions.

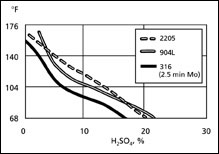

Isocorrosion Curves 4 mpy (0.1 mm/yr), in sulfuric

acid solution containing 2000 ppm

Stress Corrosion Resistance

The duplex microstructure is known to improve the stress corrosion cracking resistance of stainless steels.

Chloride stress corrosion cracking of austenitic stainless steels can occur when the necessary conditions of temperature, tensile stress, oxygen, and chlorides are present. Since these conditions are not easily controlled, stress corrosion cracking has often been a barrier to utilizing 304L, 316L, or 317L.

Corrosion Fatigue Resistence

Alloy 2205 combines high strength and high corrosion resistance to produce high corrosion fatigue strength. Applications in which processing equipment is subject to both an aggresively corrosive enviroment and to cycle loading can benefit from the properties of 2205.

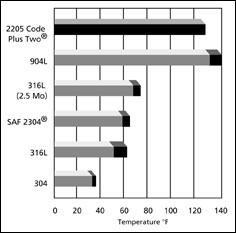

Critical Pitting Temperature in 1M NaCl Measured

Using the AvestaPolarit Pitting Cell

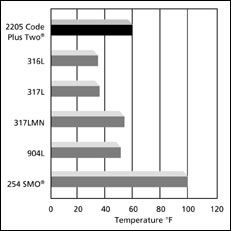

Critical Crevice Corrosion Temperature (CCT)

in 10% FeCl3•6H2O

General Corrosion in Wet Process Phosphoric Acids

| |

Corrosion Rate, ipy |

| Grade |

Solution A, 1401/4F |

Solution B, 1201/4F |

| 2205 |

3.1 |

3.9 |

| 316L |

>200 |

>200 |

| 904L |

47 |

6.3 |

| Composition, wt% |

| P2O5 |

HCl |

HF |

H2SO4 |

Fe2O3 |

| Sol A 54.0 |

0.06 |

1.1 |

4.1 |

0.27 |

| Sol B 27.5 |

0.34 |

1.3 |

1.72 |

0.4 |

| Composition, wt% |

| P2O5 |

Al2O |

SiO2 |

CaO |

MgO |

| Sol A 54.0 |

0.17 |

0.10 |

0.20 |

0.70 |

| Sol B 27.5 |

0.01 |

0.3 |

0.02 |

-- |

Stress Corrosion Cracking Resistance

(P=Pass, F=Fail)

Back to top

S31803 Stainless Steel Pipe

General Properties

Application

Standards

Chemical Composition

Resistance to Corrosion

Physical Properties

Mechanical Properties

Structure

Welding

Processing

Machinability

Corrosion of Piping

Corrosion Process

Surface Coatings for Corrosion

Corrosion Resistant Material

Bi- Metallic Corrosion.Galvanic Corrosion

1. Duplex Stainless Steel Pipe

2. Duplex Stainless Steel

3. Super-Duplex Stainless Steel

4. Principle of Duplex Stainless Steel

5. How the Austenite Ferrite Balance Achieved

6. Corrosion Resistance of Duplex Stainless Steel

7. Stress Corrosion Cracking SCC of Duplex Stainless Steel

8. Barrier to Using Duplex Stainless Steel

9. Duplex Stainless Steel Grades Comparison Table

10. S32101 | S31803 | S32205 | S32304 | S32750 | S32760

11. ASTM A789/A789M

12. ASTM A 790/A 790M

13. Duplex Stainless Steel Pipe

14. Austenitic-Ferritic Stainless Steel Pipe

15. Super-Duplex Stainless Steels and their characteristics

16. 2507 S32750 Duplex Steel Pipe

17. S31803 Stainless Steel Pipe

18. S32304(1.4362) Duplex Steel

19. S32205 Stainless Steel Pipe

20. 1.4462 Stainless Steel Pipe

21. Use of stainless steel under high temperature condition refer table

22. ASTM A789 S31803 Duplex Stainless Steel Pipe

23. ASTM A789 S32205 Duplex Stainless Steel Pipe

24. Duplex Stainless Steel Pipe Specification

25. ASTM A789 vs ASTM A790

|